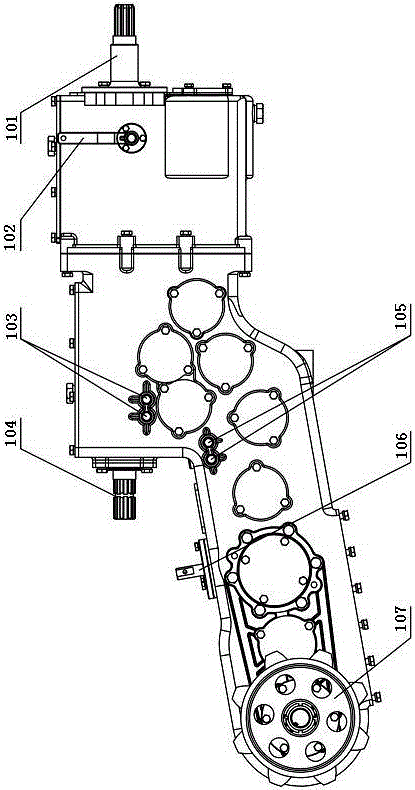

Track tractor twelve-gear transmission assembly

A tractor, twelve-speed technology, applied in the direction of vehicle gearbox, mechanical equipment, components with teeth, etc., can solve the problems of high manufacturing cost, high strength, high center of gravity, and achieve reasonable power distribution and increase the number of gears. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

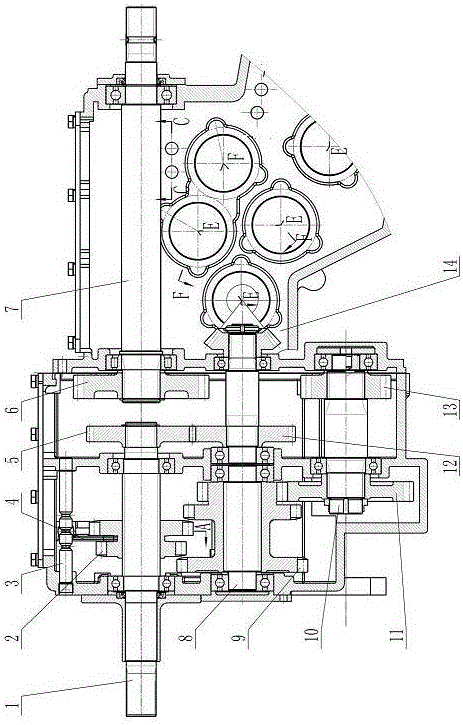

[0020] Below in conjunction with accompanying drawing the present invention is described in detail as follows

[0021] exist figure 2 Among them, the power input shaft 1 is installed in the front box, the rotary tillage active dual gear 2 is installed on the power input shaft 1, the rotary tiller shift fork 4 is placed in the rotary tiller active dual gear 2, and the rotary tiller gear shift The fork 4 is fixed on the shift fork shaft 3 of the rotary tillage, the driving gear 5 of the input shaft is installed on the end of the power input shaft 1, and the passive gear 6 of the rear box rotary tillage output shaft is installed on the rear box rotary tiller output shaft 7 , the rotary tillage intermediate shaft 8 is equipped with the triple tooth 9 of the rotary tillage intermediate shaft and the passive tooth 12 of the front box travel output shaft, the front box travel output shaft passive tooth 12 meshes with the input shaft travel active tooth 5, and the end of the rotary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com