Automatic generation method and device for compressor control system

An automatic generation and control system technology, applied in the direction of pump control, machine/engine, mechanical equipment, etc., can solve the problem that the unit control system cannot meet the requirements of high efficiency and high accuracy, shorten the development cycle, improve work efficiency, reduce The effect of program error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

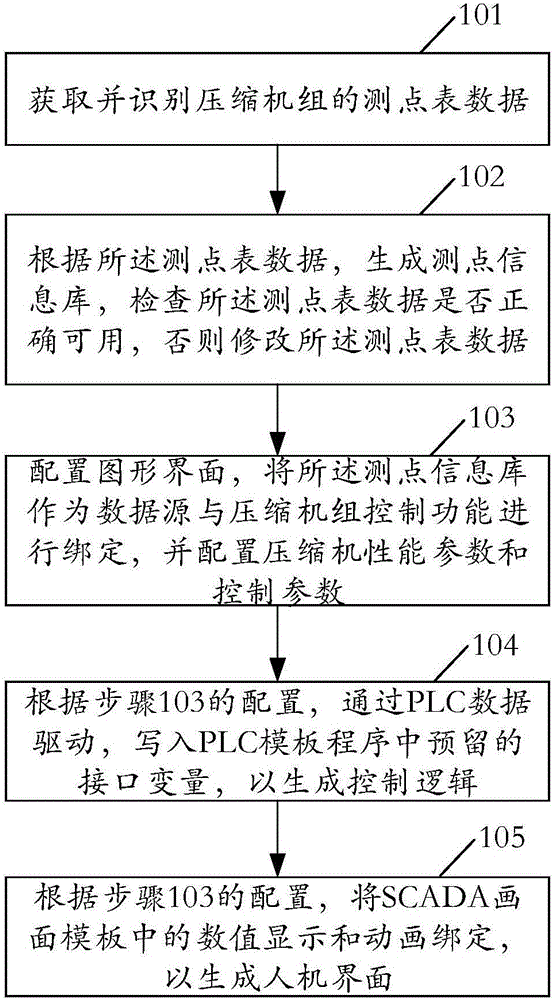

[0022] like figure 1 As shown, it is a flowchart of an automatic generation method for a compressor control system, including:

[0023] Step 101, acquiring and identifying the measuring point table data of the compressor unit;

[0024] Wherein, the measuring point table data includes measuring point number, description, range, alarm upper and lower limits, interlock upper and lower limits, etc.;

[0025] Step 102, generate a measuring point information database according to the measuring point table data, check whether the measuring point table data is correct and available, otherwise modify the measuring point table data;

[0026] Wherein, checking whether the measuring point data is correct and available is mainly to judge whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com