Automatic control system of high-efficiency and energy-saving type asphalt mixture stirring equipment

An automatic control system, asphalt mixture technology, applied in roads, road repairs, roads, etc., to achieve the effect of reducing power consumption, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

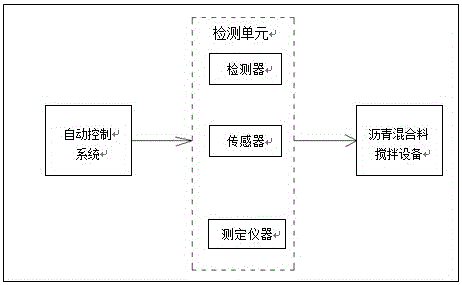

[0013] Such as figure 1 As shown, an automatic control system of high-efficiency and energy-saving asphalt mixture mixing equipment, the automatic control system automatically detects the asphalt mixture mixing equipment through the detection unit. The detection unit includes detectors (current detectors, voltage detectors, etc.), sensors (pressure sensors, temperature sensors, speed sensors, carbon monoxide sensors, nitrogen oxide sensors, sulfide sensors, oxygen sensors, grayscale sensors, load cells, Position sensors, combustible gas sensors, etc.), measuring instruments (viscosity measuring instruments). The asphalt mixing equipment is equipped with a burner, a monitoring frequency converter, an induced draft fan and a drying drum. The control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com