Method and device for conveying reel cassette for electronic component packaging carrier tape

A technology for electronic components and conveying devices, which is used in packaging, transportation and packaging, and coiling strips, etc., can solve problems such as complex structure and procedures, the path for the throwing of the cassette is too far, and the conveying path of the cassette is not smooth. , to achieve the effect of simple mechanism, light load and smooth transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

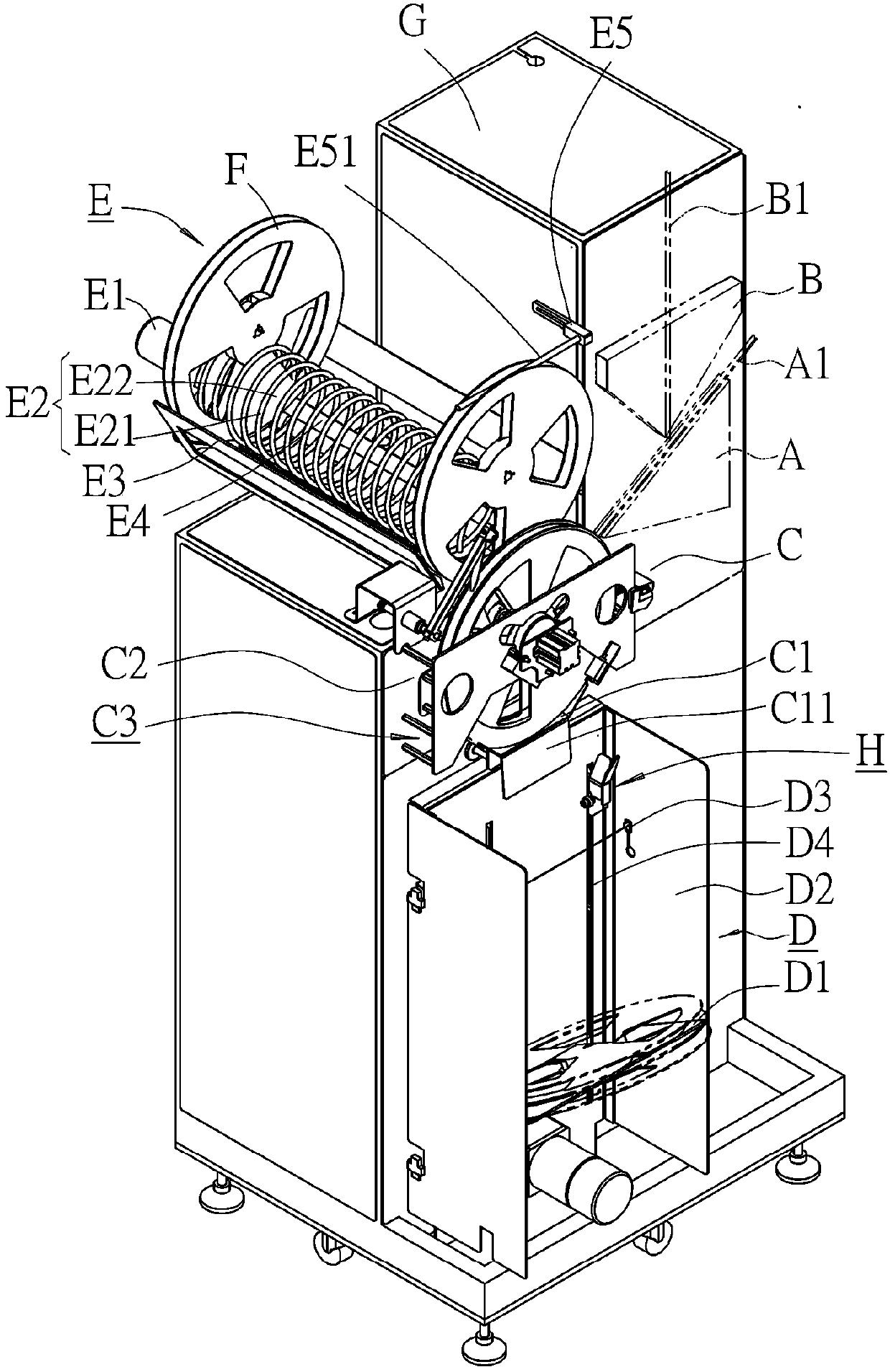

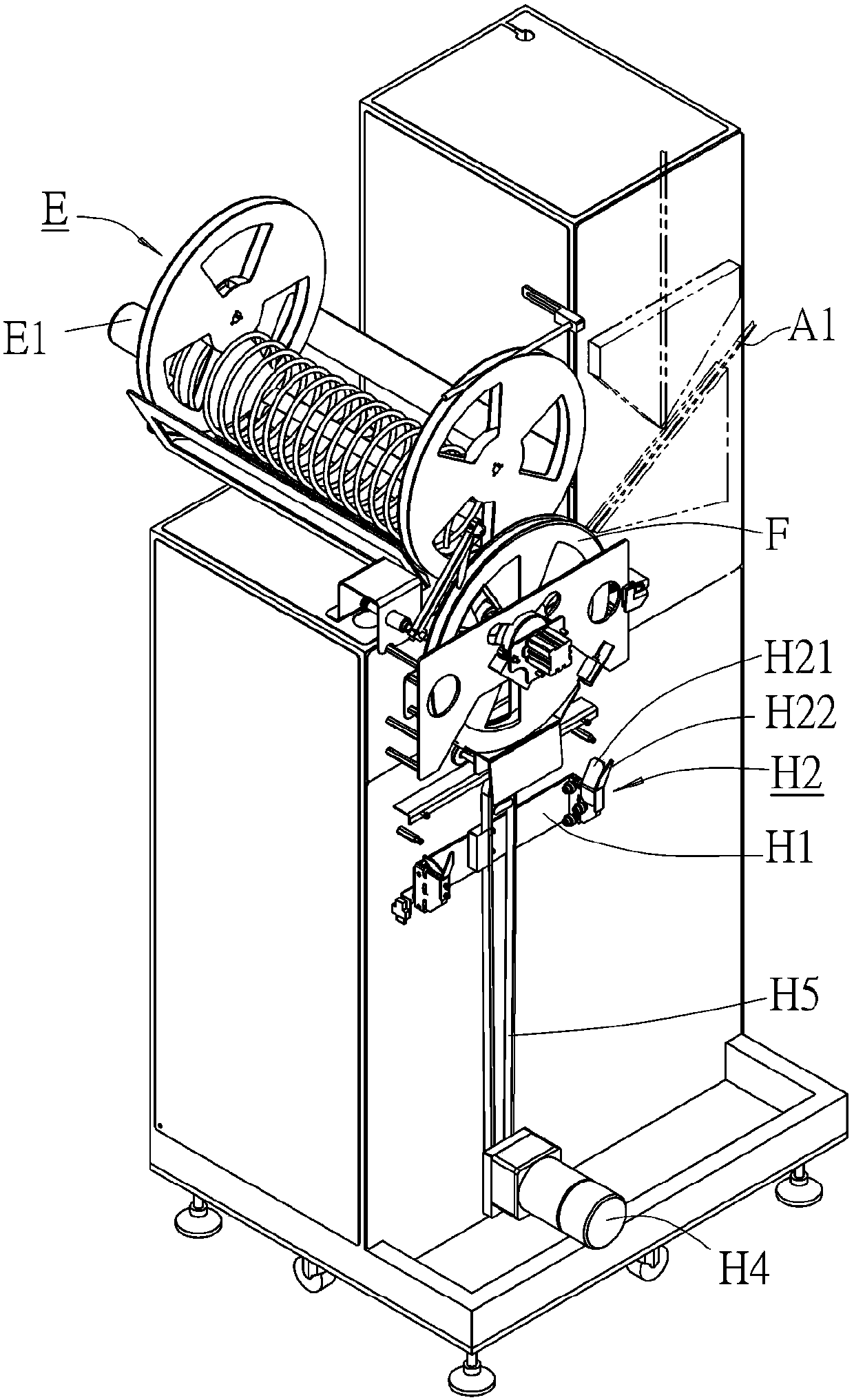

[0038] see figure 1 , 2 , the embodiment of the method and device for conveying the electronic component packaging carrier tape of the present invention can be described with the device shown in the figure, including:

[0039] A carrier tape conveying device A, used to convey the carrier tape A1 that has been placed in the electronic components;

[0040] A sticker conveying device B, used to convey stickers B1;

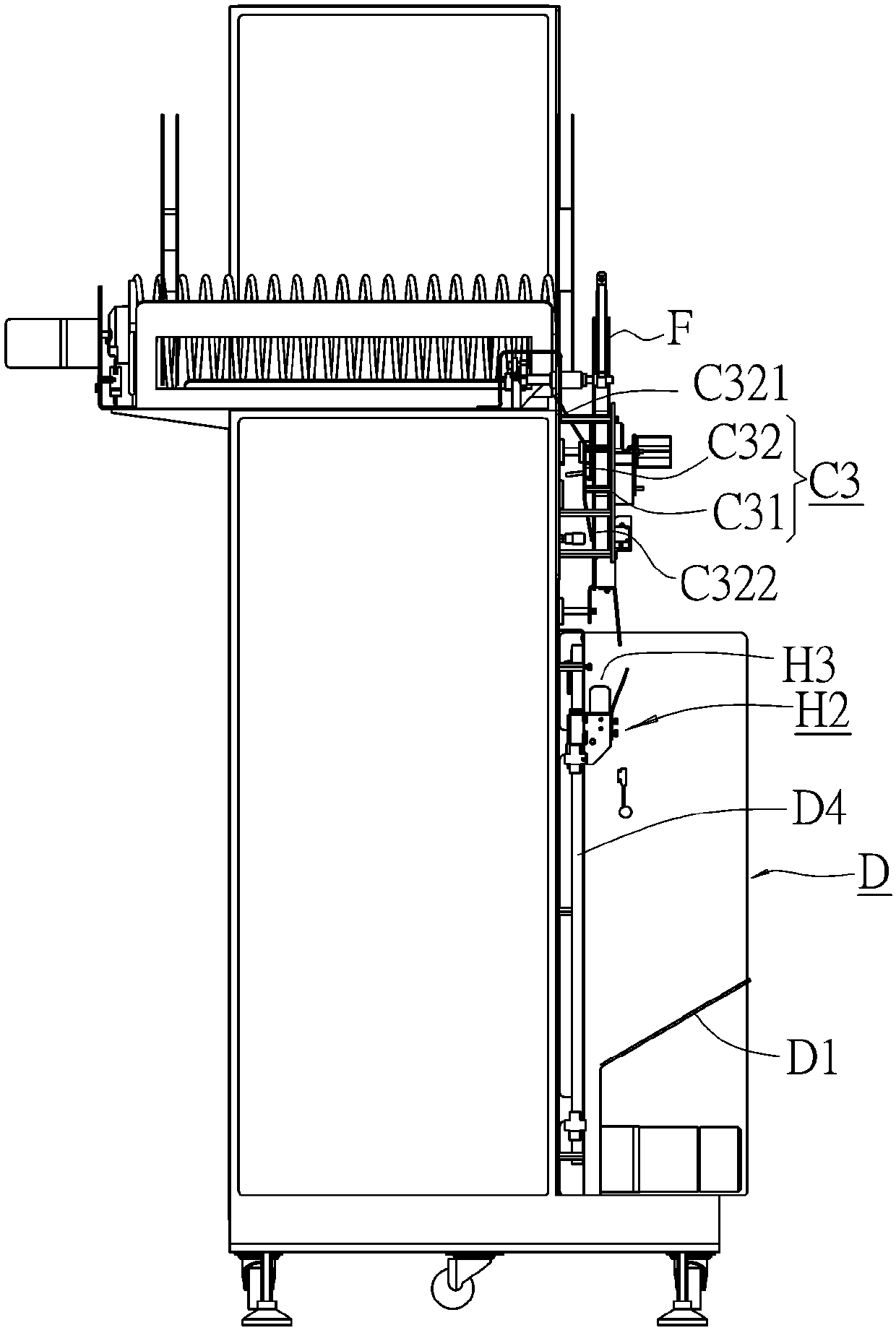

[0041] A winding device C, which winds up the carrier tape A1 attached to the sticker B1 conveyed by the sticker conveying device B, which includes a bracket C1 that can be driven for forward and backward displacement, and is located above the bracket C1. A carrier C3 providing a loading space C2; the bracket C1 is provided with a guide surface C11 on the front side; the carrier C3 includes a side frame C31 located on the front side of the loading space C2, and behind the rear side of the loading space C2 Side frame C32, wherein, a rearwardly deflected guide port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com