A positive and negative pressure forming mold

A forming mold, positive and negative pressure technology, applied in metal processing and other directions, can solve the problem of unsatisfactory cutting results, achieve high cutting efficiency, improve stability, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

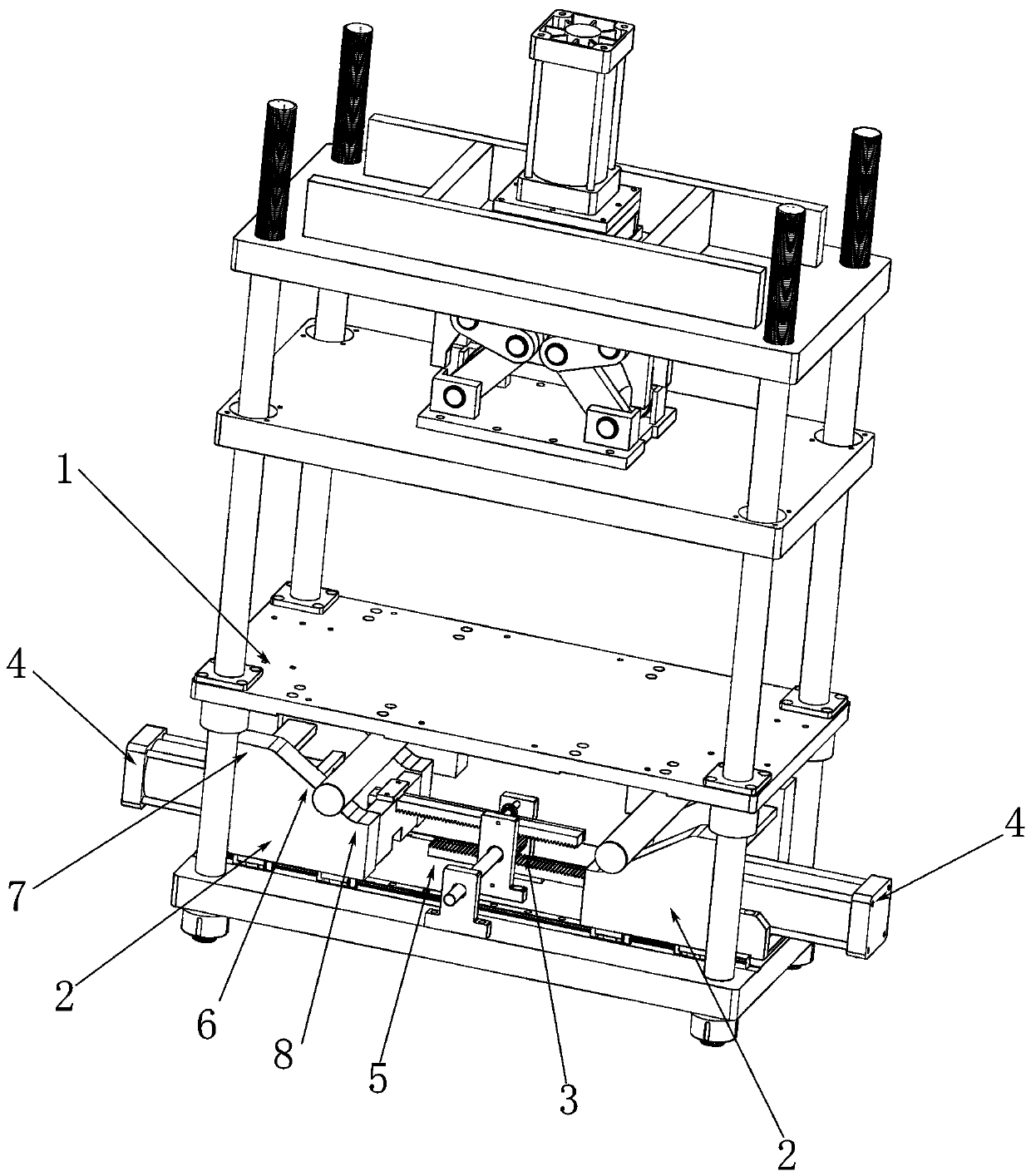

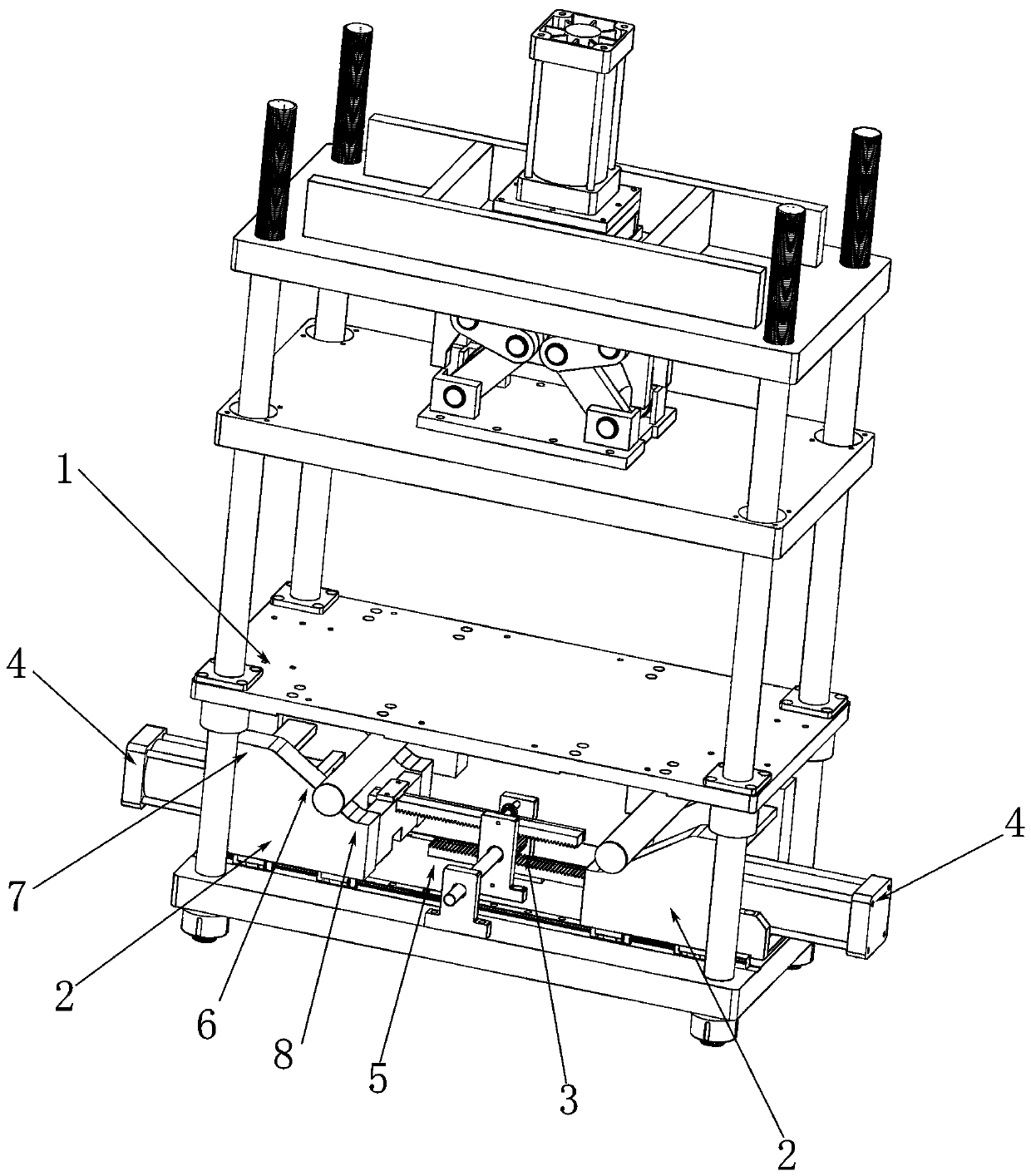

[0015] The invention relates to a positive and negative pressure molding die, comprising an upper die and a lower die. Such as figure 1 As shown, the lower mold includes a carrier 1, a sliding module 2 and a cutting module. A rotating shaft 3 with fixed rotation is arranged at the center below the carrier 1 .

[0016] The symmetrical part of the sliding module 2 is below the carrier platform 1 , and the two ends of the sliding module 2 are respectively connected with a driving module 4 and a guide block 5 . The two guide blocks 5 roll on the rotating shaft 3 respectively. In order to further improve the stability, both the surface of the rotating shaft 3 and one side of the sliding block can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com