Mechanism for punching side wall of firefighting main machine shell

A technology for the side wall of the shell and the fire-fighting main engine, which is applied in the direction of the feeding device, manufacturing tool, positioning device, etc., can solve the problems of low punching efficiency, punching error, troublesome fixing, etc., and achieve accurate punching, high efficiency, Firm clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

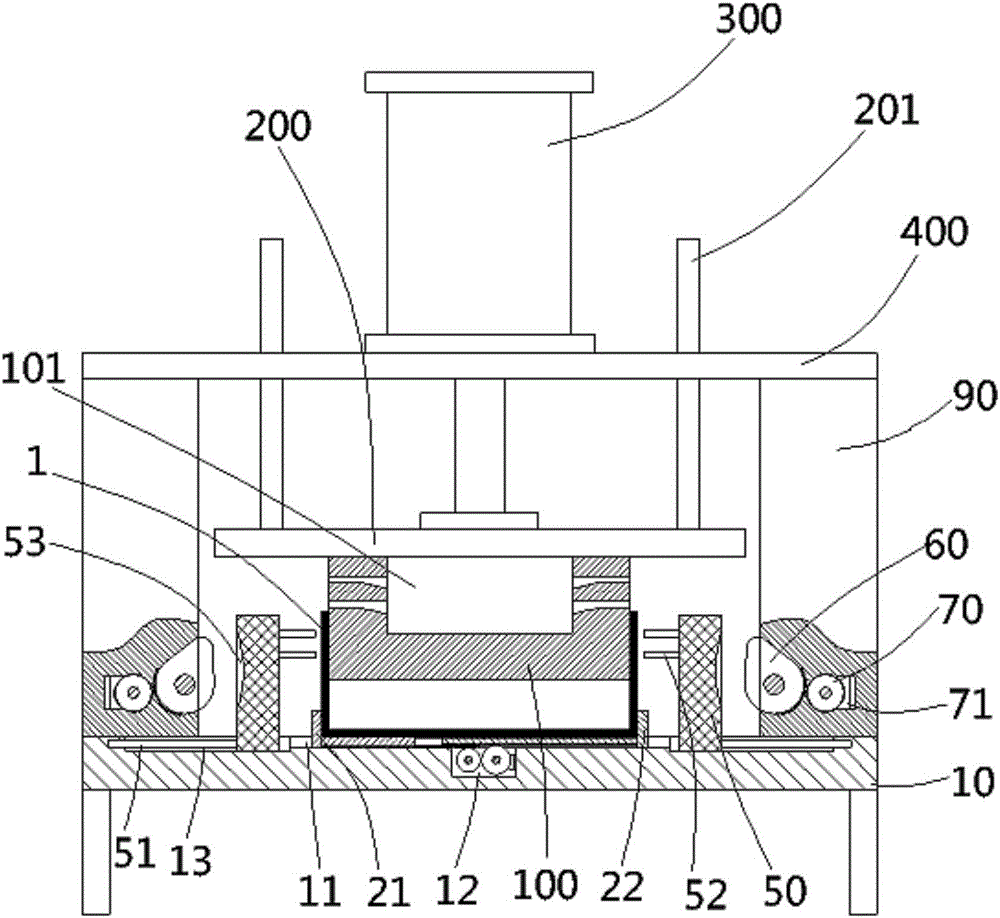

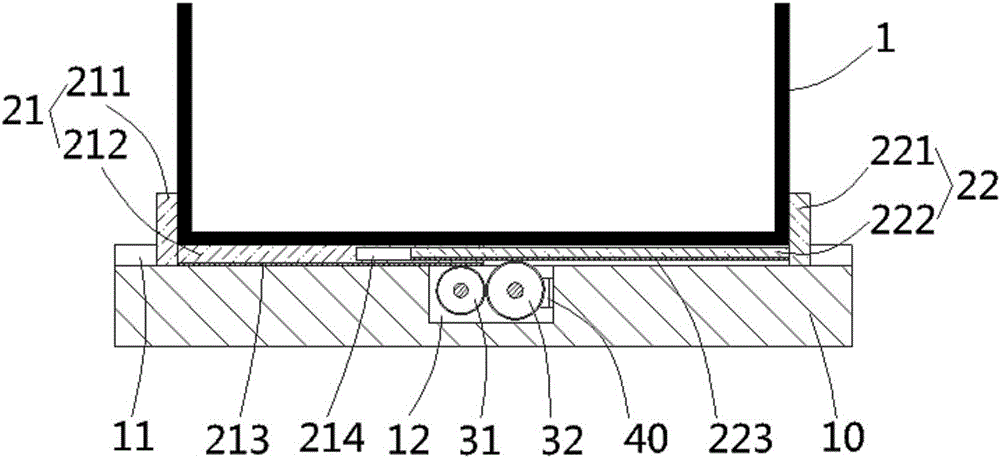

[0022] see figure 1 , figure 2 , a kind of mechanism that is used for punching the side wall of fire main engine housing described in the present invention, comprises frame 10, and the middle part of the top surface of described frame is formed with slot 11, and described slot is inserted and sleeved with The first clamping plate 21 and the second clamping plate 22 that are both “L” shaped and oppositely arranged, and the first clamping plate 21 and the second clamping plate 22 are respectively connected to the two sides of the shell 1 to be processed. Correspondingly, the first clamping plate 21 includes a first vertical plate 211 and a first horizontal plate 212 perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com