Device used for replacing wide and thick plate rolling mill hydraulic AGC cylinder and using method thereof

A wide and thick plate rolling mill technology, which is applied in the field of replacing the hydraulic AGC cylinder of wide and heavy plate rolling mills, can solve the problems of manpower and equipment, long time, and many steps, and achieve the effects of saving maintenance time, convenient manufacture, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

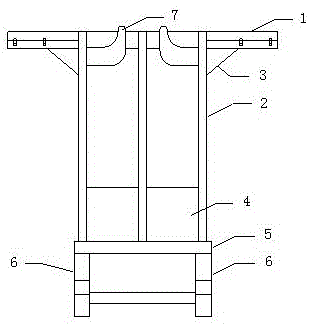

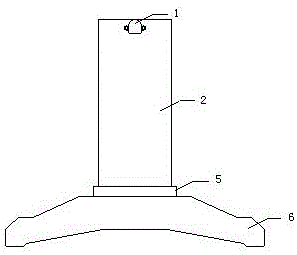

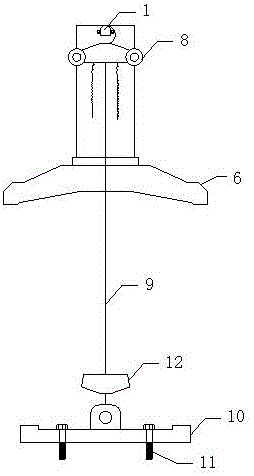

[0033] In the device for replacing the hydraulic AGC cylinder of the wide and heavy plate rolling mill of the present invention, the hydraulic AGC cylinder of the wide and heavy plate rolling mill is arranged in the pit at the lower part of the two rolling mill arches. The two rolling mill arches are L-shaped and arranged oppositely. In the middle position of the L-shaped rolling mill arch, the device for replacing the hydraulic AGC cylinder of the wide and heavy plate rolling mill includes a girder support unit and two electric hoists.

[0034] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the beam support unit according to the embodiment of the present invention, figure 2 for figure 1 side view. As shown in the figure, the beam support unit includes a beam, a support plate, a rib plate, and a base. The beam 1 is a long 2060mm long steel beam; the two sides of the beam are welded to the top of the support plate 2, and the beam is...

Embodiment 2

[0037] The device using method for replacing the hydraulic AGC cylinder of the wide and heavy plate rolling mill of the present invention comprises the following steps:

[0038] a. Put the device for replacing the hydraulic AGC cylinder of the wide and heavy plate rolling mill on the work roll changing guide rail with the 50t crane and movable hydraulic unit in the wide and heavy plate mill workshop, and use the work roll change device to replace the hydraulic AGC of the wide and heavy plate rolling mill. The device of the cylinder is pushed into the rolling mill stand to ensure that the base 6 of the device for replacing the hydraulic AGC cylinder of the wide and heavy plate rolling mill is correctly in contact with the L-shaped rolling mill arches on both sides, and the device for replacing the hydraulic AGC cylinder of the wide and heavy plate rolling mill is placed After stabilization, the operator will open the pit cover, and then use the conveyor roller changing device to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com