Automatic washing pipette unit

A pipette and washing liquid technology, applied in the field of washing liquid pipetting devices, can solve the problems of increasing the labor intensity of operators, excessively long showering time, and many washing times, and achieves good environmental protection effect, easy batch cleaning and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

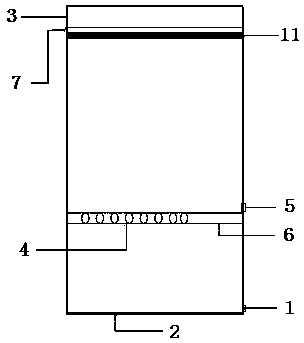

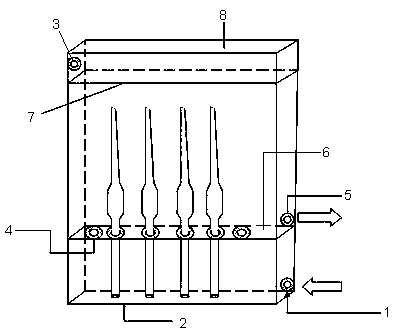

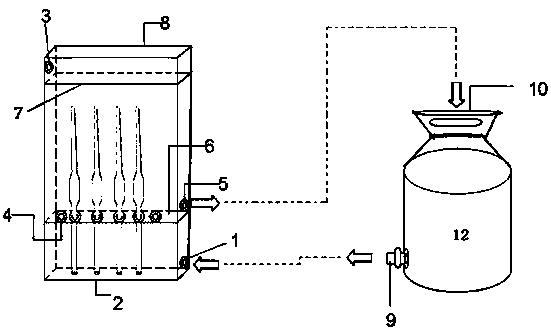

[0027] In this example, see Figure 1~5 , an automatic washing pipette device, which is composed of a container and a liquid flow inlet 1 and a liquid flow outlet 5 installed on the side wall of the container. The container is made of plexiglass transparent material. The section of the container is square. Shaped side wall, base 2 and openable sealing cover 8 enclose to form a box-type washing chamber, the container is formed by a barrel-shaped side wall and base 2 into a tank-shaped container, and a movable pipette is used to fix the mounting plate 6. A series of pipette insertion mounting holes 4 are distributed on the pipette fixing mounting plate 6, so that the tip of the pipette to be washed is installed upside down in the mounting hole 4, and the pipette to be washed can be placed in the mounting hole 4. The pipette is arranged on the pipette fixed mounting plate 6, and also adopts a rubber stopper. When the part of the mounting hole 4 on the pipette fixed mounting plate...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

[0036] In this embodiment, a lotion supply switch valve is provided on the lotion supply pipe 9, and a faucet is used as a source of cleaning water. On and off are controlled separately. This embodiment is also very convenient, can improve cleaning efficiency, is easy to control, and saves power consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com