External circulating DTB fluidized bed crystallizer

A fluidized bed and external circulation technology, applied in the direction of solution crystallization, evaporation separation crystallization, etc., can solve the problems of increased crystal nucleation rate, increased fine crystals, frequent collisions, etc., and achieve the elimination of supersaturation and uniform crystal particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

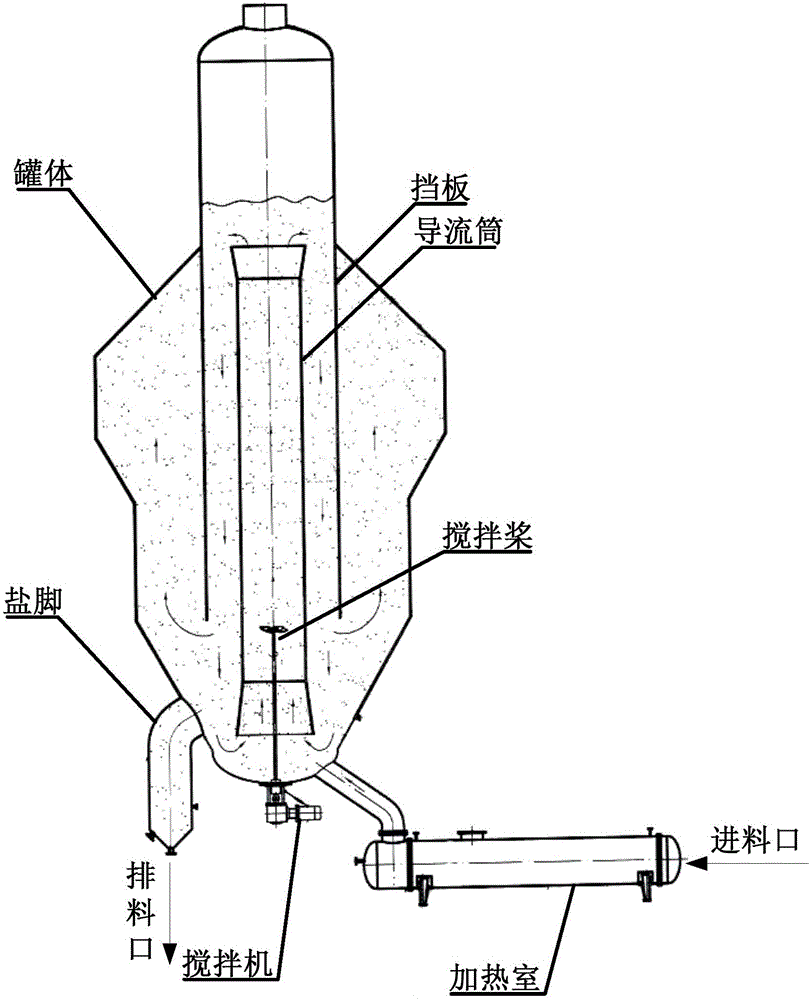

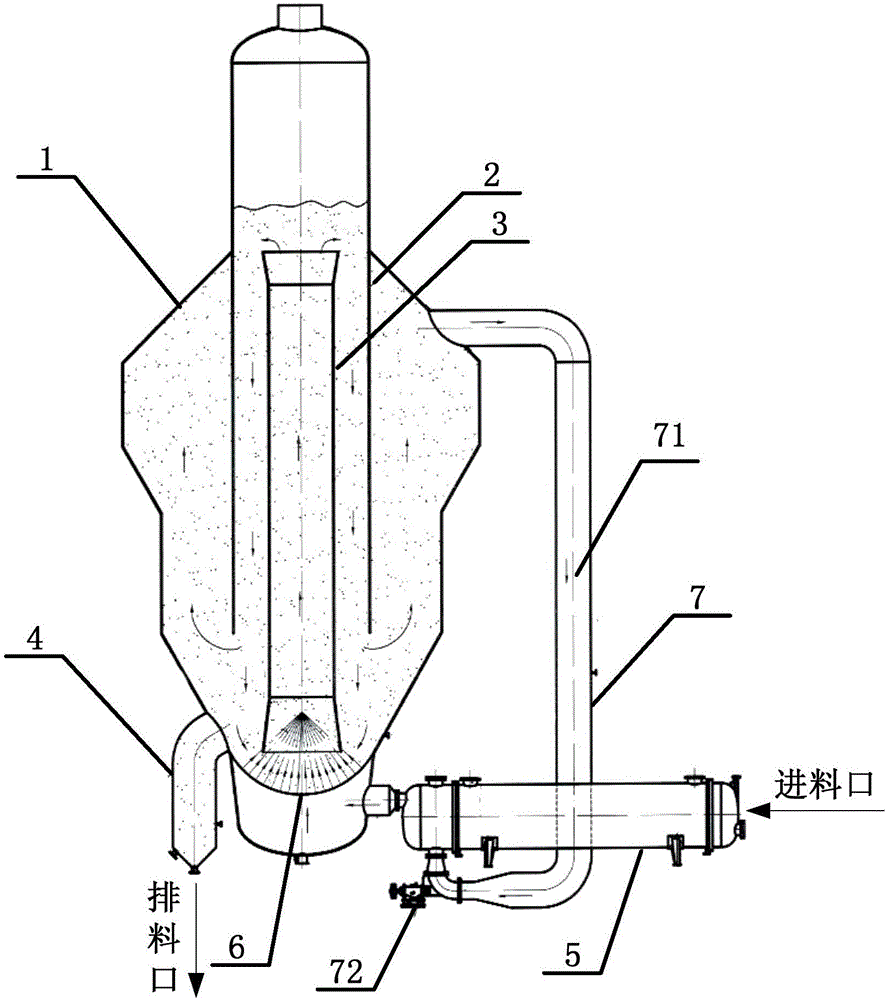

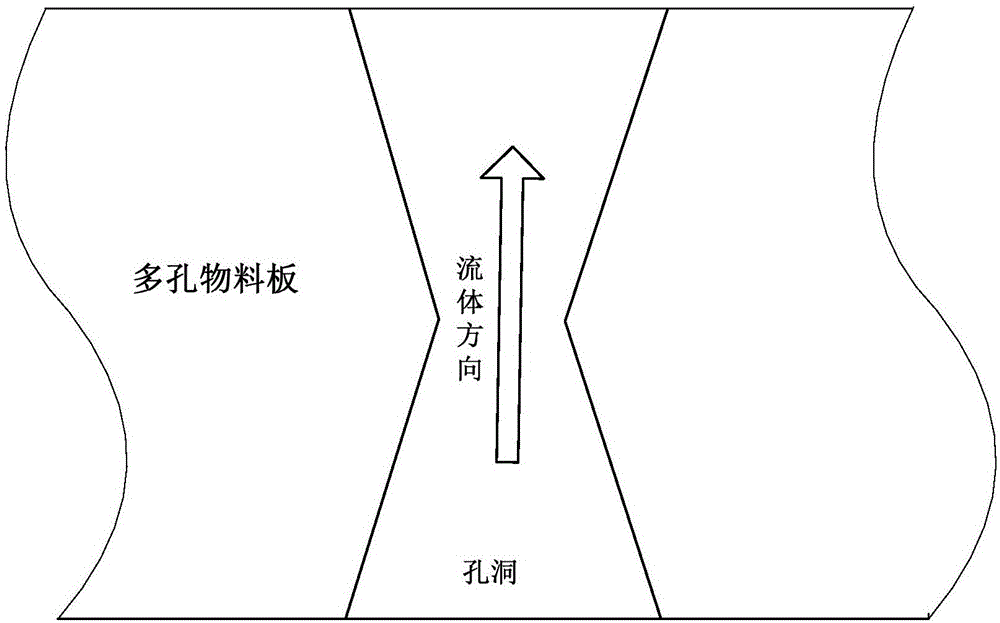

[0013] figure 2 It is a structural diagram of a specific embodiment of the external circulation DTB fluidized bed crystallizer of the present invention. Such as figure 2 As shown, the external circulation DTB fluidized bed crystallizer of the present invention includes a tank body 1, a baffle plate 2, a draft tube 3, a salt foot 4, a heating chamber 5, a porous distribution plate 6, and an external circulation device 7. Wherein the structure and function of the tank body 1, the baffle plate 2, the guide tube 3, the salt foot 4, and the heating chamber 5 are similar to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com