Modularization sole structure

A modular, sole technology, applied in soles, footwear, clothing and other directions, can solve the problems of inconvenient walking, bad walking habits, deformation of the wearer's walking posture, etc., to achieve the effect of convenient adjustment, prevention of sagging feet, and delaying wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

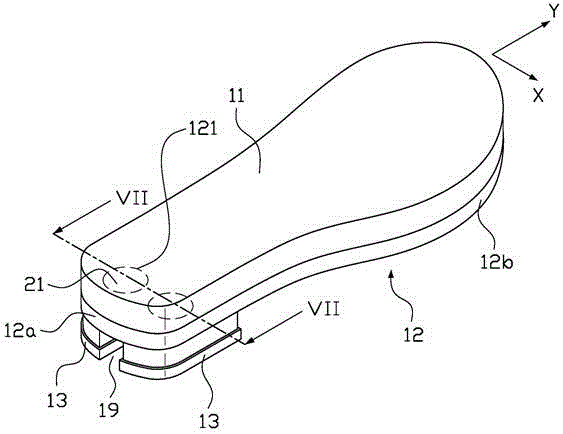

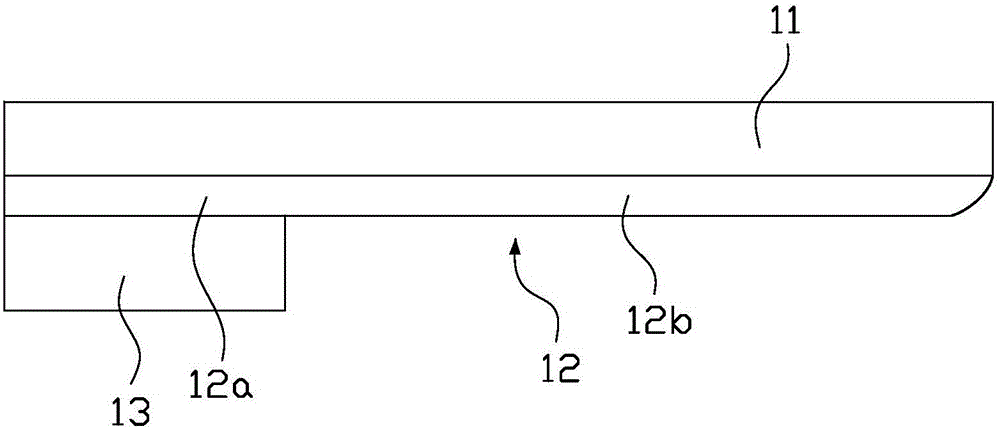

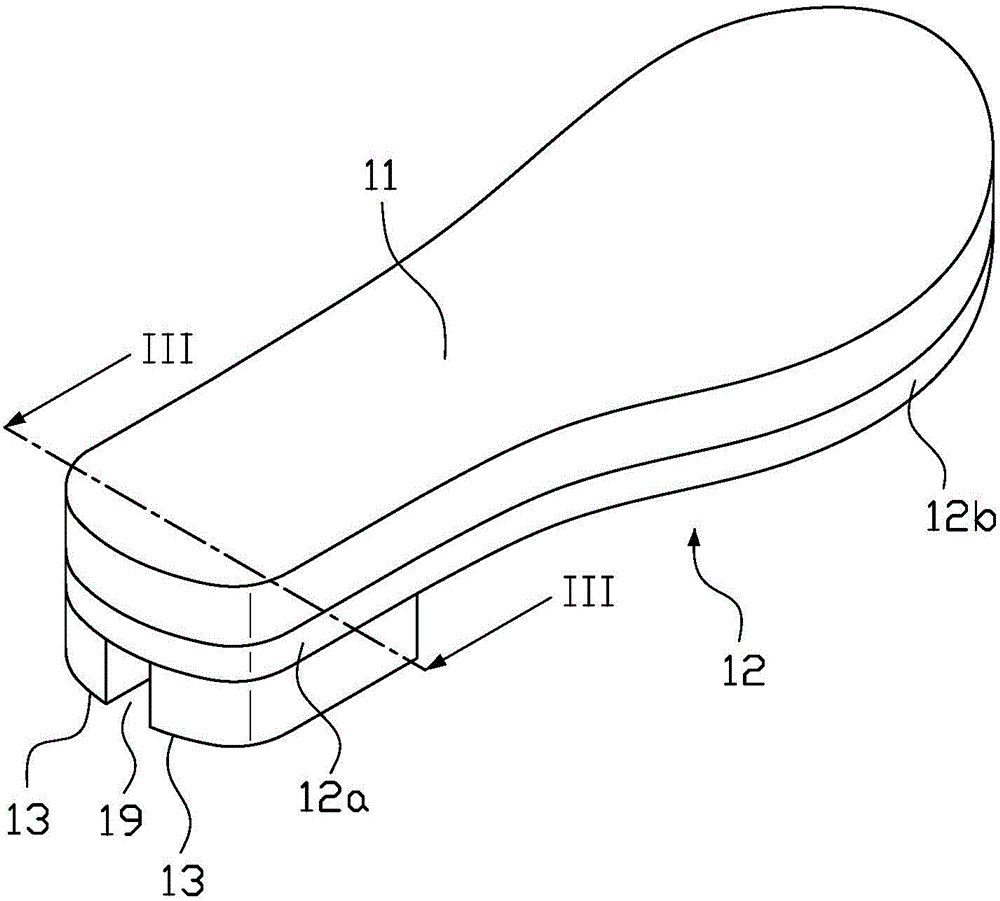

[0051] figure 1 It is a schematic diagram of the front view of the sole structure in the first embodiment of the present invention, figure 2 for figure 1 For the three-dimensional assembly diagram of the sole structure in , please refer to Figure 1 to Figure 2, the sole structure in this embodiment includes an insole 11 and a sole 12, the sole 12 is provided with at least one protrusion 120, and the protrusion 120 is equipped with a detachable anti-friction cushion block adapted to the protrusion 120 at the bottom near the ground 13. The insole 11 is arranged on the sole 12, but according to actual conditions, the insole 11 can also be omitted.

[0052] Figure 3a to Figure 3e for figure 2 Schematic diagrams of the cross-sectional structures of different examples along the line III-III, please refer to Figure 3a to Figure 3e , the wear pad 13 includes a wear pad 131 in contact with the ground and a fixed fin 132 arranged on the periphery of the wear pad 131 and conne...

no. 2 example

[0060] Figure 4 It is a schematic diagram of the front view of the sole structure in the second embodiment of the present invention, Figure 5 for Figure 4 The three-dimensional exploded schematic diagram of the sole structure in Image 6 for Figure 4 The three-dimensional assembly diagram of the sole structure in Figure 7 for Image 6 Schematic diagram of the cross-sectional structure along line VII-VII. Please refer to Figure 4 to Figure 7 , in this embodiment, the protrusion 120 is provided with an airbag chamber 121, and the airbag chamber 121 is provided with an airbag body 21, and the airbag chamber 121 and the airbag body 21 can be stretched and compressed. The airbag chamber 121 and the airbag body 21 can be arranged in a part of the protrusion 120 or in all of the protrusions 120. By setting the airbag chamber 121 and the airbag body 21 in the protrusion 120, the cushioning and shock absorption of the sole structure can be effectively improved. effect, and...

no. 3 example

[0062] Figure 8 It is a three-dimensional exploded schematic view of the sole structure in the third embodiment of the present invention, Figure 9 for Figure 8 Schematic diagram of the structure of the insole of the sole structure in the upward view, Figure 10 for Figure 8 The three-dimensional assembly diagram of the sole structure in Figure 11 for Figure 10 The schematic diagram of the cross-sectional structure along the line XI-XI in the middle. Please refer to Figure 8 to Figure 11 , in the present embodiment, every two protrusions 120 are distributed in a row in the left-right direction (X direction in the figure) of the sole 12, and the airbag bodies 21 in the two protrusions 120 of each row are connected by The tube 22 is connected as one. Specifically, a plurality of rows of protrusions 120 may be arranged along the front and rear direction (Y direction in the figure) of the sole 12, two protrusions 120 of each row are distributed along the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com