A superconducting cyclotron vacuum exhaust system

A cyclotron and vacuum exhaust technology, which is applied in the direction of magnetic resonance accelerators, electrical components, accelerators, etc., can solve the problems of intensified multi-electron effects, small effective pumping speed of the accelerating cavity, and beam acceleration, etc., to achieve high vacuum environment Requirements, increase the vacuum gain rate, and reduce the effect of beam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

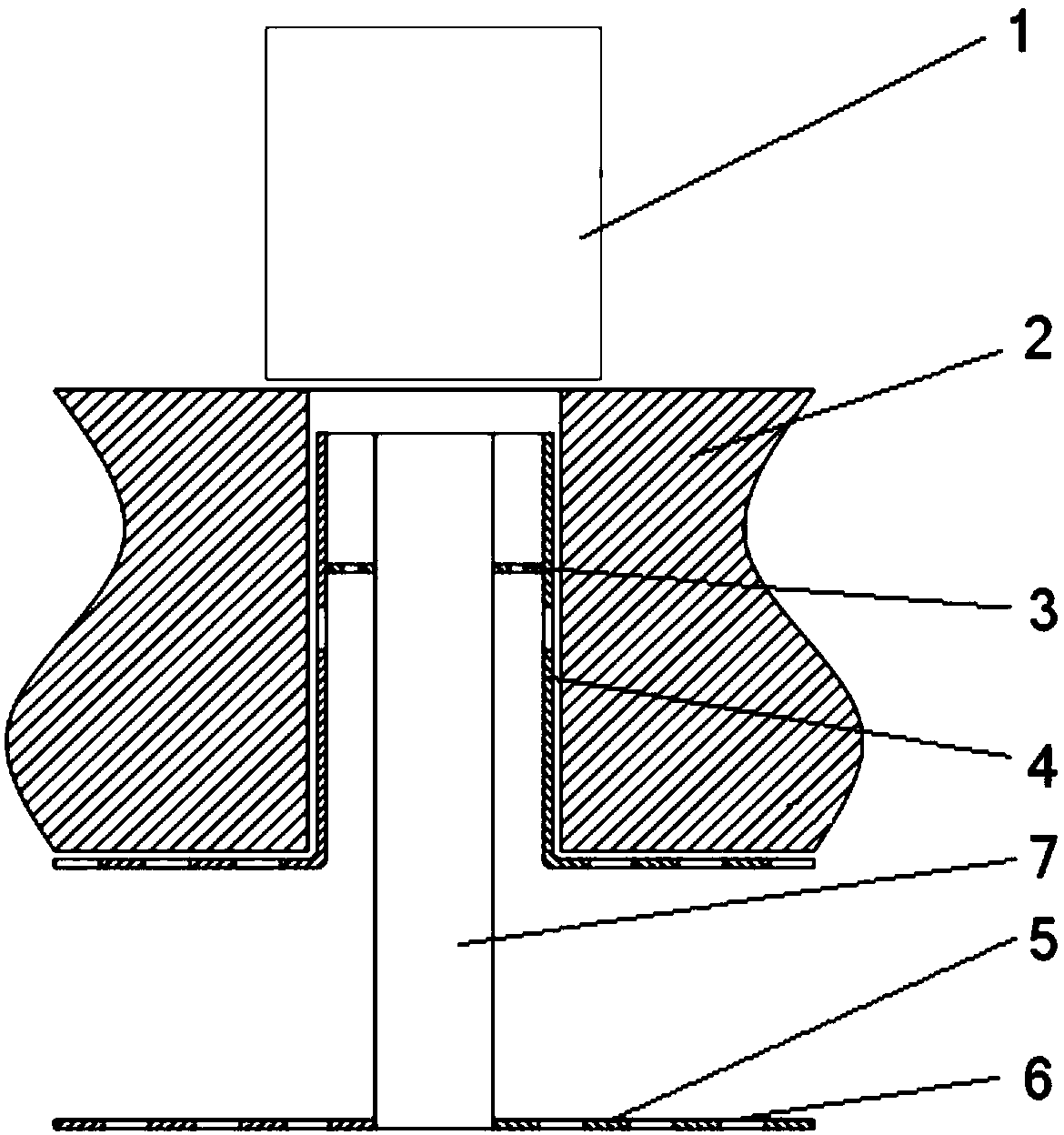

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, it is a partial structure diagram of the superconducting cyclotron vacuum exhaust system provided by the present invention. The superconducting cyclotron vacuum exhaust system includes a first exhaust passage, a second exhaust passage and a third exhaust passage. The first exhaust passage is arranged in the high-frequency inner rod 7 of the superconducting cyclotron high-frequency system, the second exhaust passage is arranged between the high-frequency inner rod 7 and the high-frequency outer conductor 4 of the high-frequency system, and the third row The air passage is set between the high-frequency outer conductor 4 of the superconducting cyclotron and the main magnet cover plate 2 of the superconducting cyclotron; the first exhaust passage, the second exhaust passage and the third exhaust pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com