Ultrasonic flaw detection tool for steel plate

An ultrasonic and tool technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. Low manufacturing cost, wide application range, and the effect of solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

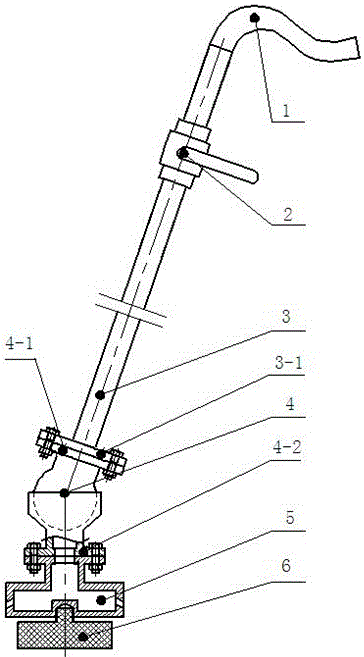

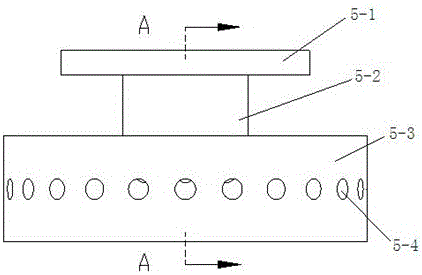

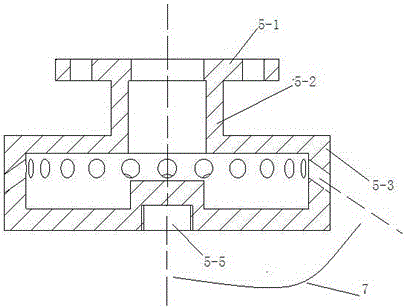

[0021] Specific implementation methods: such as figure 1 As shown, the present invention provides a steel plate ultrasonic flaw detection tool, which includes a flaw detection head 6, and also includes a connecting pipe 3, a fluid universal joint 4 and a water spray device 5 connected together in sequence, and the flaw detection head 6 is arranged on the water spray device 5 Below, between the connecting pipe 3 and the fluid universal joint 4, between the fluid universal joint 4 and the water spray device 5, and between the water spray device 5 and the flaw detection head 6 are all detachable connections. Among them, when holding the flaw detection steel plate on the top of the connecting pipe 3, as the horizontal distance between the flaw detection point and the human body changes, the angle between the connecting pipe 3 and the water spray device 5 changes, and the fluid universal joint 4 can ensure that the flaw detection head 6 and the The plates are always in surface cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com