A multi-channel percussion detection device for a composite material adhesive structure

A composite material and detection device technology, applied in measurement devices, analysis materials, material analysis using sonic/ultrasonic/infrasonic waves, etc. Improve damping, good detection effect, high percussion frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

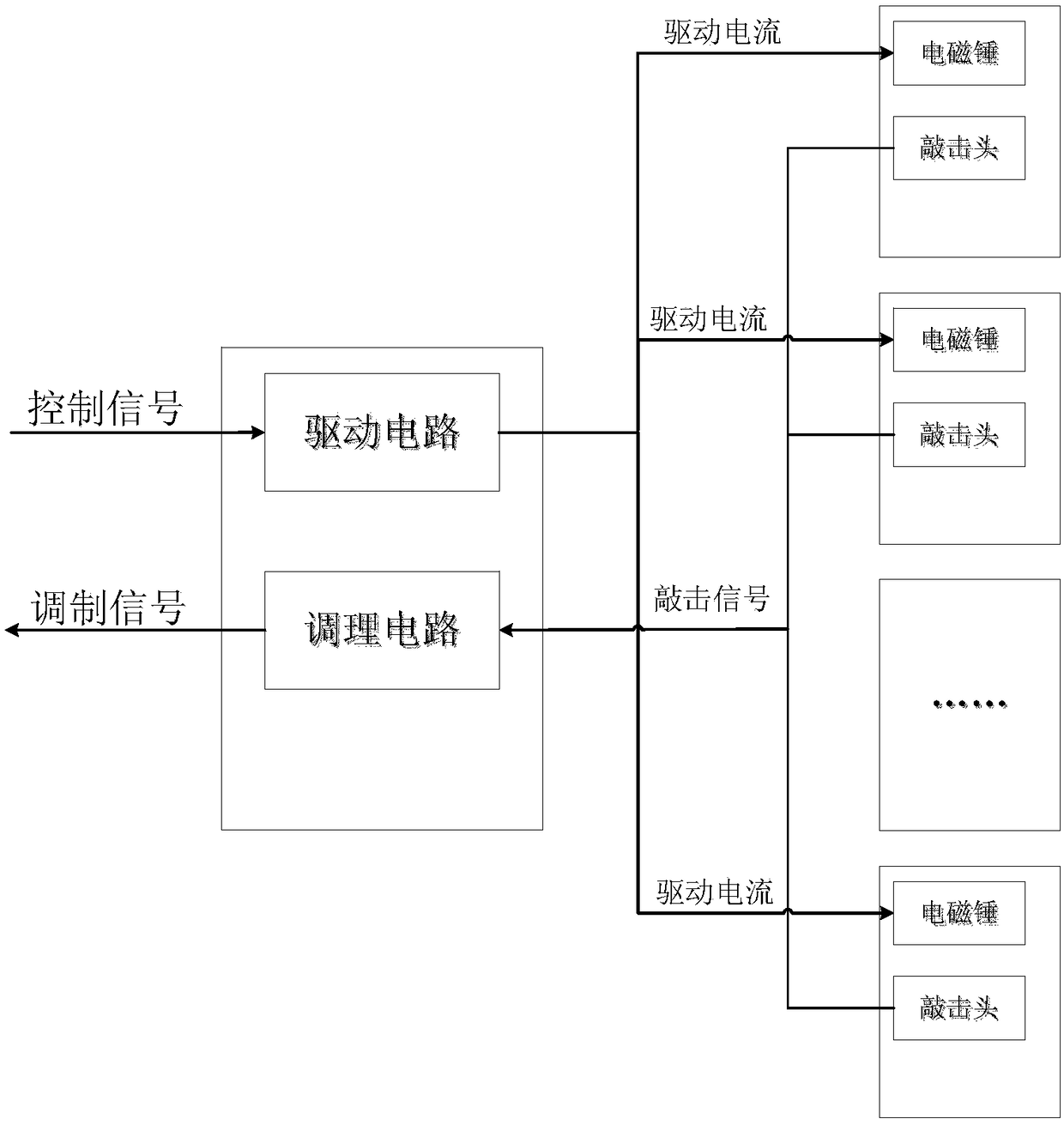

[0029] figure 1 It is a schematic diagram of a multi-channel percussion detection device for a composite material bonded structure. As shown in the figure, the multi-channel percussion detection device includes a drive circuit, a conditioning circuit, N electromagnetic hammers and N percussion heads, and the percussion heads correspond to the electromagnetic hammers one by one, wherein:

[0030] The drive circuit receives external input control signals, generates 2N drive current signals, and outputs them to N electromagnetic hammers at the same time;

[0031] The conditioning circuit receives the knocking signals collected by N knocking heads, amplifies, filters and compares the knocking signals to generate modulated signals and output them to external devices;

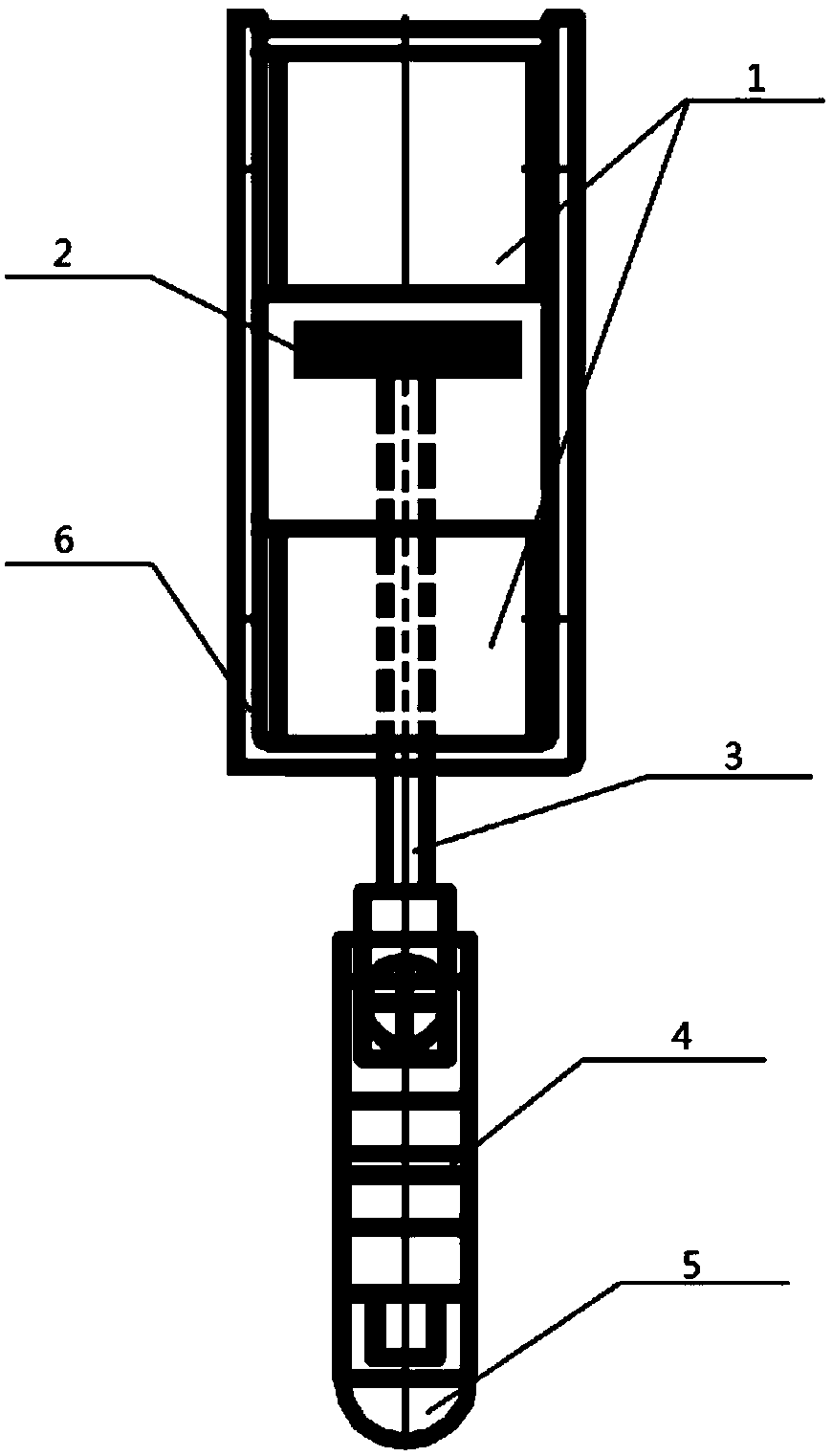

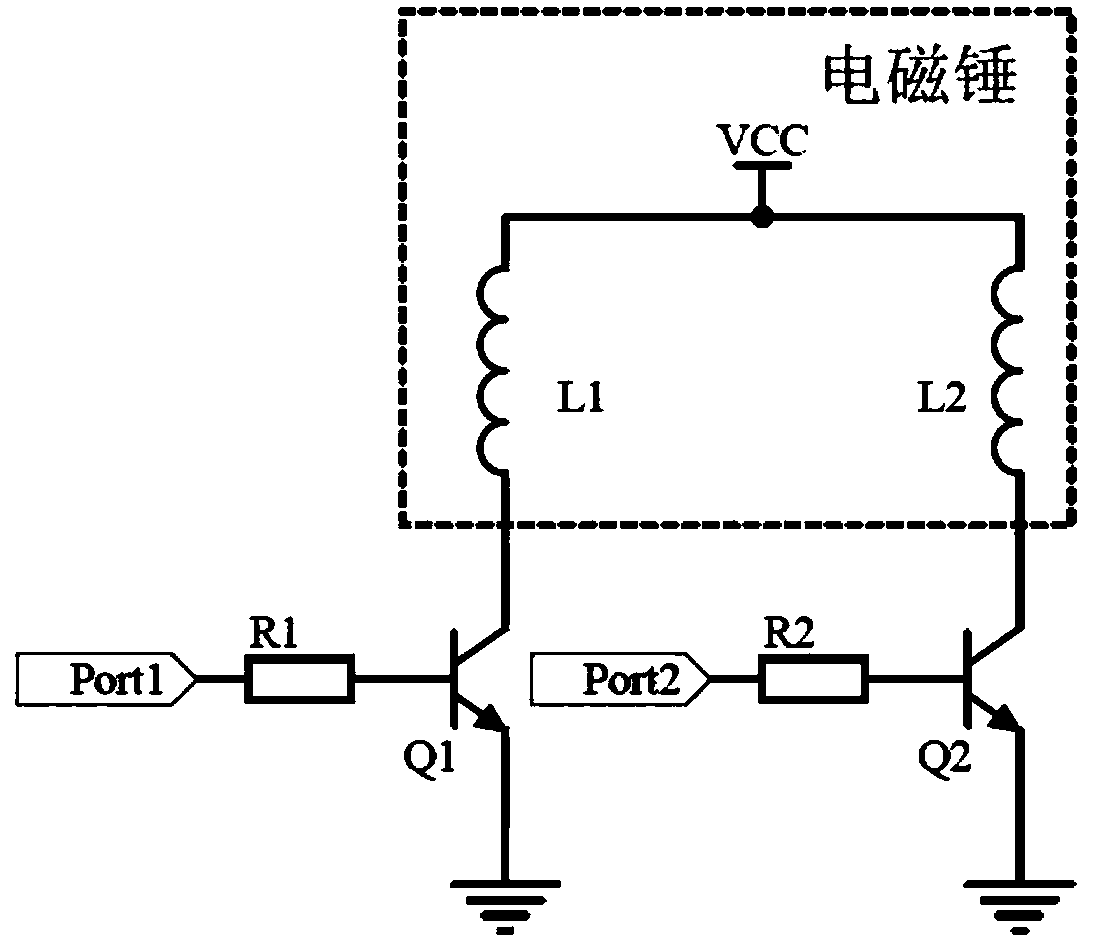

[0032] Electromagnetic hammer, including two electromagnetic coils and a metal slide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com