Blasting simulation test device and blasting simulation test method on basis of geo-mechanical model tests

A model test and geomechanics technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc. It can solve the problem that true three-dimensional loading cannot be achieved, the impact of blasting effects is not considered, and the size of the test device is small. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

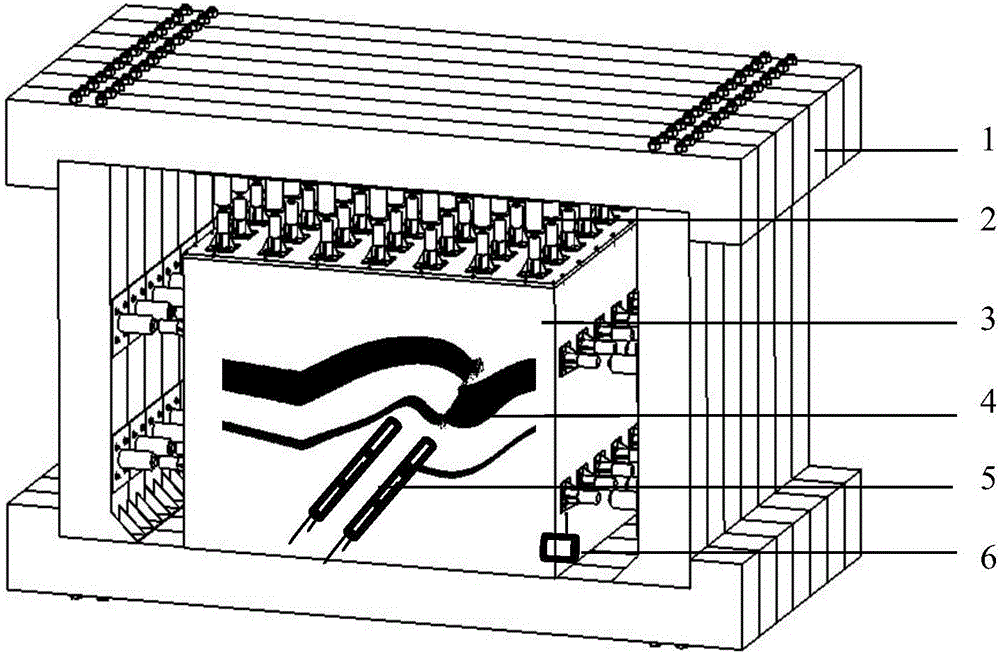

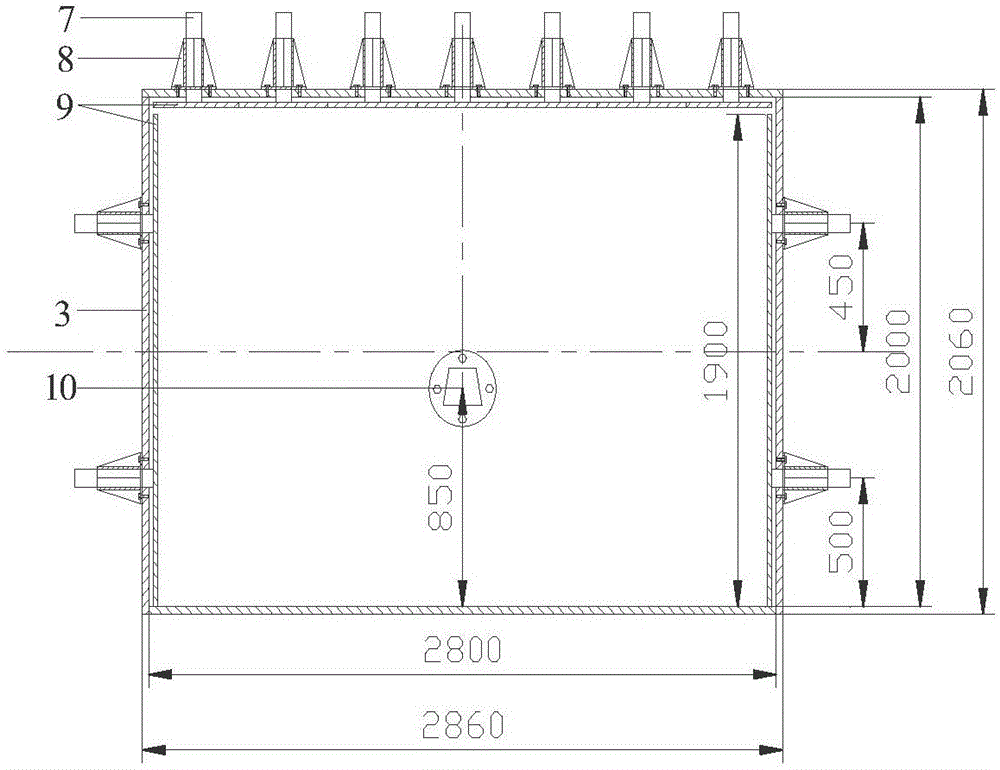

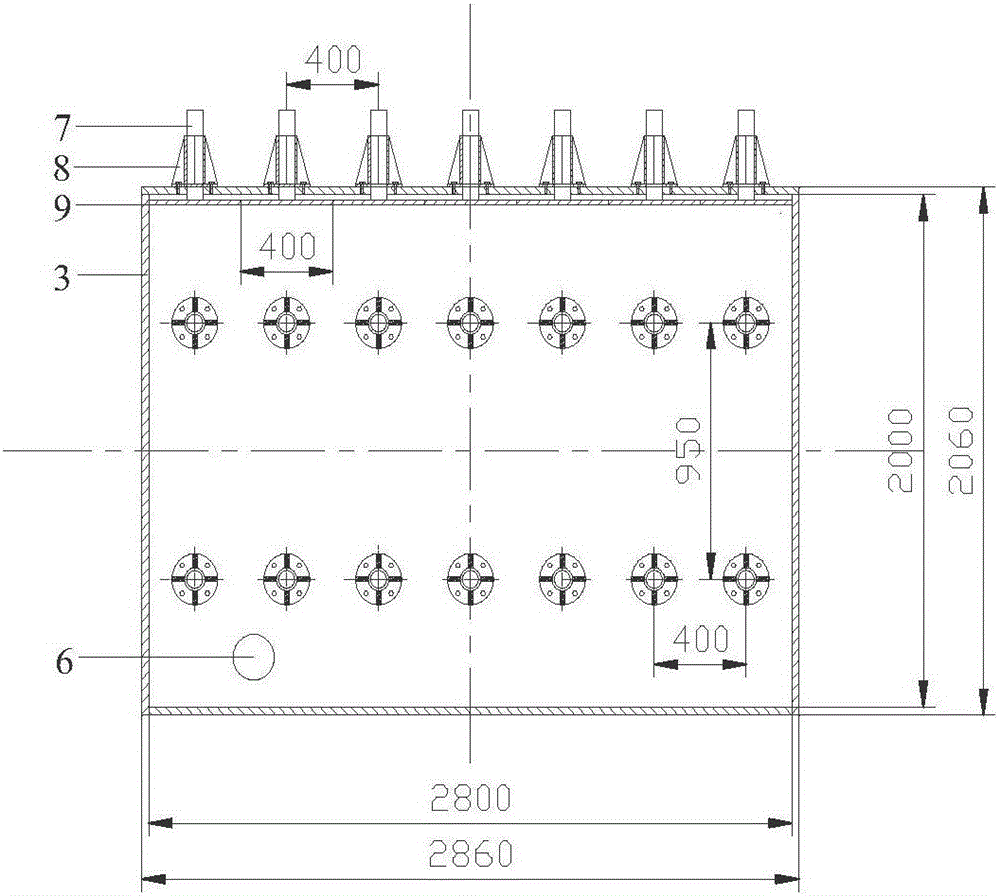

[0028] Example: such as Figure 1-Figure 8 As shown, the large-scale three-dimensional blasting simulation test device mainly includes hydraulic loading systems (1) and (2), and a test box (3); the data monitoring sensor wiring port (6) is arranged in the test box (3) Lower right side: the micro-dose controlled blasting technology, filling the blasting hole with RDX or detonating cord (17) and connecting the detonator (18), sealing the hole with yellow mud, and detonating the detonator through the detonator for blasting Simulation test.

[0029] In this embodiment, by analyzing the control effect of tectonic movement on the development of geological weak-faced coal body, the structural belt area where the coal seam structure is damaged is selected as the test model for blasting to disturb the geological weak-faced coal body, and the geological coal body test model of the structural belt ( 4). Coal powders of different particle sizes were used as aggregates, and sodium humate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com