Marine fuel oil supply device and method

A technology for supplying device and fuel, applied in charging system, combustion engine, fuel injection control, etc., can solve the problems of old control method, unable to respond in time, pressure and viscosity value to provide engine, etc., to achieve clean oil. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a kind of marine fuel oil supply device:

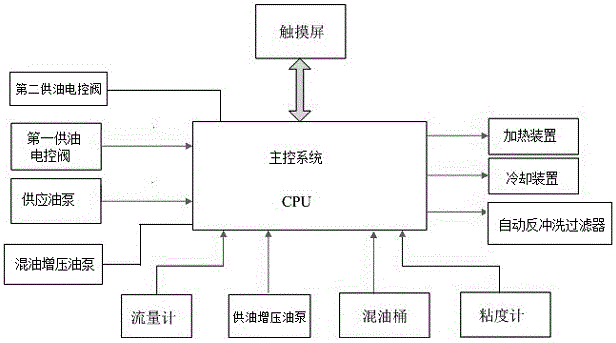

[0037] refer to figure 1 , the marine fuel oil supply device includes a mixed oil tank 9, an oil tank 1 and a main control system, and the described oil tank 1 is selected from at least 2 or 3 kinds of diesel tanks, gas oil tanks and heavy oil tanks; in the mixed oil tank 9 An oil mixing pipeline 5 is provided between the oil tank 1 and an oil supply pipeline 14 is provided between the oil mixing barrel 9 and the engine;

[0038] The oil mixing pipeline 5 is provided with a first oil supply electric control valve 2, a filter 3, an oil supply pump 18 and a flow meter 8 in sequence according to the direction of oil delivery;

[0039] The oil supply pipeline 14 is provided with an oil supply booster pump 7, a second oil supply electric control valve 19, and a viscometer 12 in sequence according to the oil delivery direction; A heating device 11 and a cooling device 10 are arranged in parallel; two oil supply booste...

Embodiment 3

[0042] Embodiment 3, in the marine fuel supply device described in Embodiment 1 or 2: the oil-mixing booster pump 4 is also connected in parallel on the supply oil pump 18, and the oil-mixing booster pump 4 is connected to the CPU through a signal line. There are 2 permanent oil-mixing booster oil pumps 7, one for constant and one for standby.

Embodiment 4

[0043] Embodiment 4, in a kind of marine fuel oil supply device described in embodiment 1 or 2 or 3: also be provided with automatic backwash filter 13 on the fuel supply pipeline 14 of the rear stroke of viscometer 12, automatic backwash filter 13 13 is connected with the CPU through a signal line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com