Externally-adjusting spring jar

A jar and jarring technology, which is applied in wellbore/well components, earthwork drilling, vibration generating devices, etc., can solve the problems of small jarring force, moderate jarring force of tubular jars, and complicated processing. , to achieve the effect of convenient operation, strong shock force and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

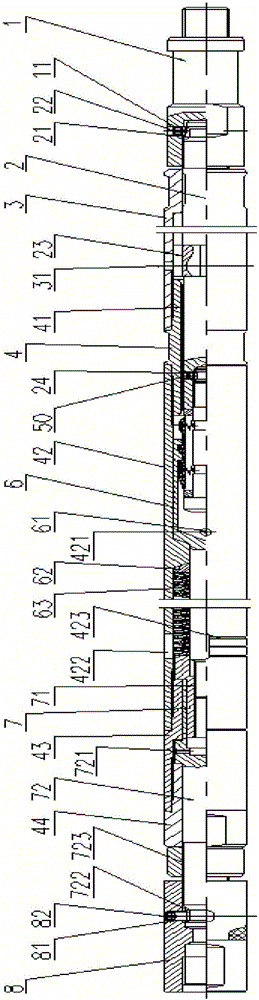

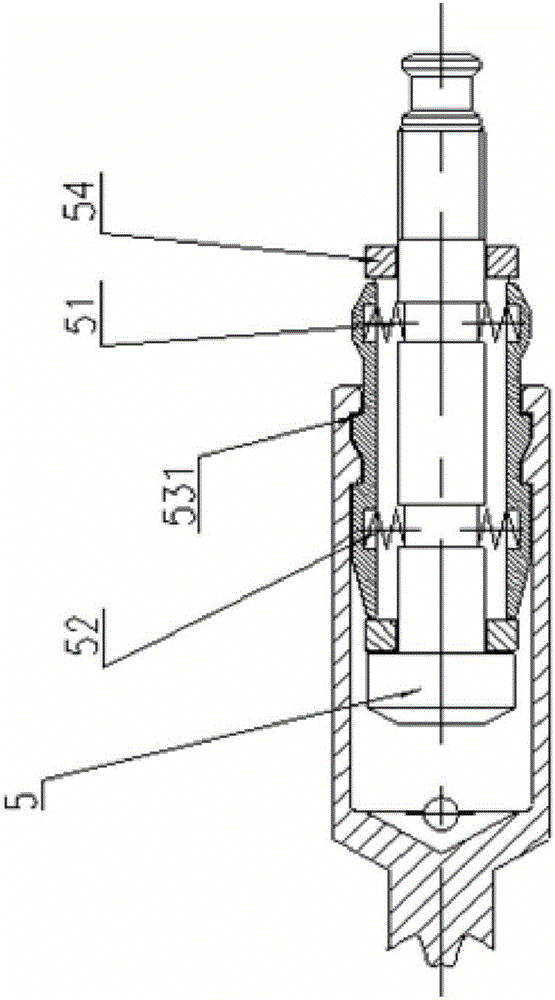

[0020] like Figures 1 to 4 As shown, the externally adjustable spring jar of the present invention includes a fishing neck 1, a jarring rod 2, a sleeve 3, a connecting nipple 4, a jarring connecting rod 5, an extension rod 6, an inner adjusting rod 7 and a lower joint 8.

[0021] The fishing neck 1 has a rod-shaped structure, its upper end is connected with an external tool string, and its lower end is provided with a fishing neck screw hole 11 along the radial direction.

[0022] The upper end of the shock rod 2 is sleeved inside the lower end of the fishing neck 1 and a screw mounting groove 21 is provided in the radial direction. A set screw 22 is fixed to the lower end of the fishing neck 1; at the same time, the inner wall of the lower end of the shock rod 2 is provided with threads, and the middle section is provided with a ventilating groove 23 in the radial direction, and the lower end of the shock rod 2 is positioned at the bottom of the ventilating groove 23. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com