Outer-hanging type automatic rod replacing drilling machine

A plug-in, automatic technology, used in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of inconvenient maintenance, high use cost, high price, etc., and achieve good stability, space saving, and good hinge stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

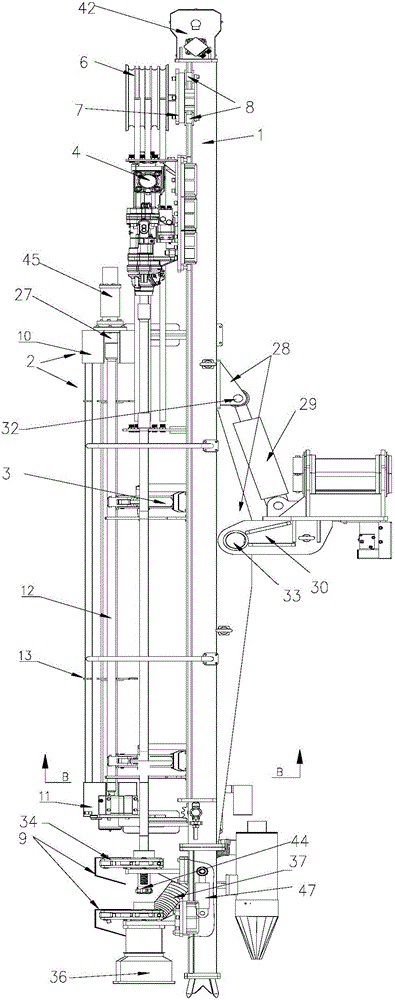

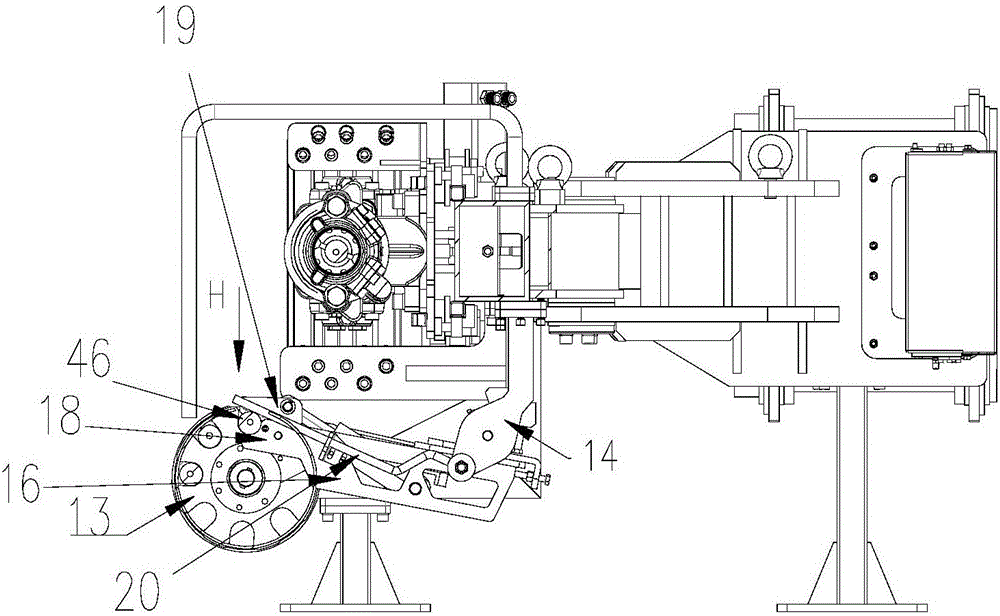

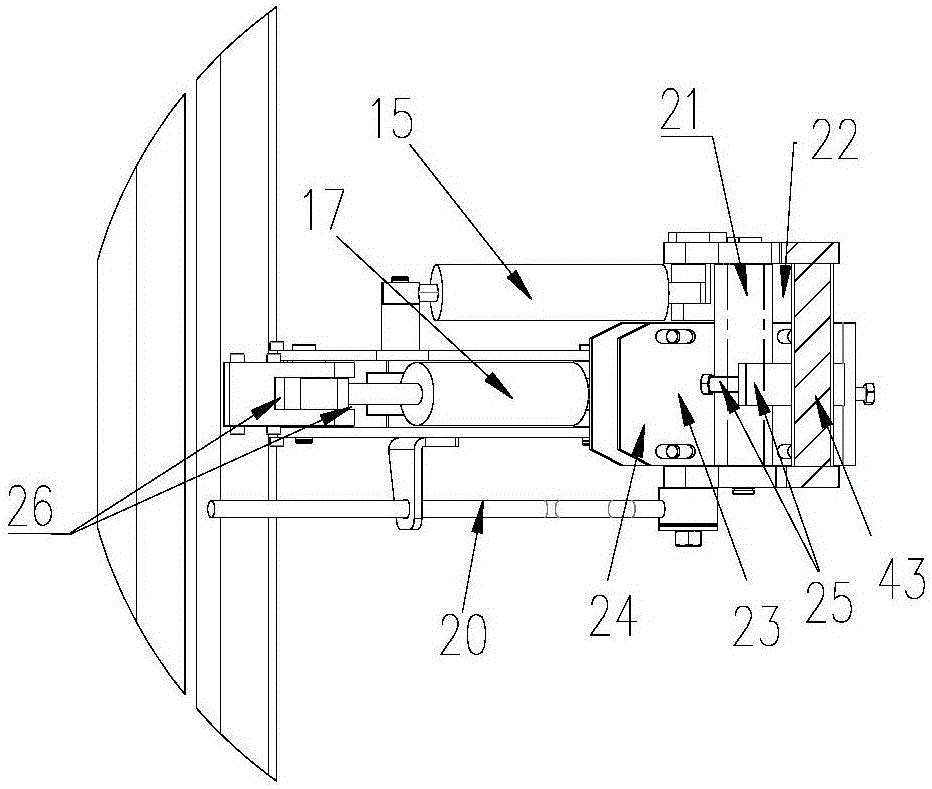

[0037] refer to figure 1 , figure 2 , the present embodiment includes a guide rail 1, a transmission mechanism, a pipe winding mechanism, a clamping device, a rod storage device 2, a manipulator 3, and a rock drill 4; the guide rail 1 is a vertical plate provided with a guide groove or a guide rod; the transmission mechanism includes a power Source, transmission device, lifting wheel 5 that can roll up and down along the guide rail; the winding mechanism includes a drum 6 with a plurality of grooves, a mounting bracket 7, the drum is fixed on the lifting wheel 5, the mounting bracket 7 and the moving guide wheel 8 Fixed connection, the mobile guide wheel 8 can slide up and down in the guide rail; the clamping device is a plurality of holders 9 installed on the guide rail; the rod storage device includes an upper end cover 10, a lower end cover 11, a rotating shaft 12, and a solid rod chuck 13 , the upper end cover 10 and the lower end cover 11 are respectively located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com