Automatic poling vehicle for transmission stringing engineering

A technology of power transmission frame and pole car is applied in the field of electric power engineering, which can solve the problems of low efficiency and multiple labor force, and achieve the effects of high sensitivity, labor force reduction and work efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

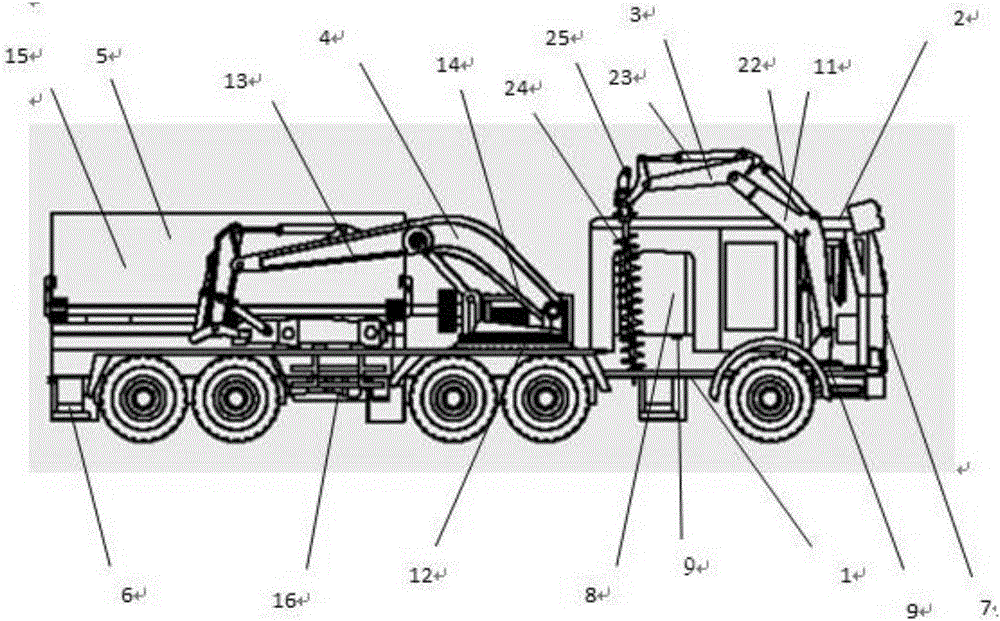

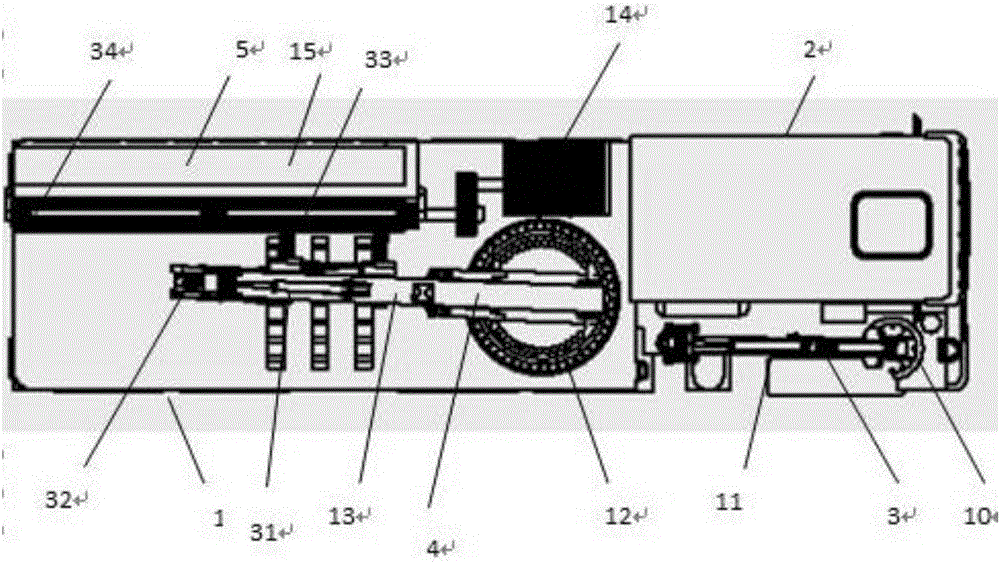

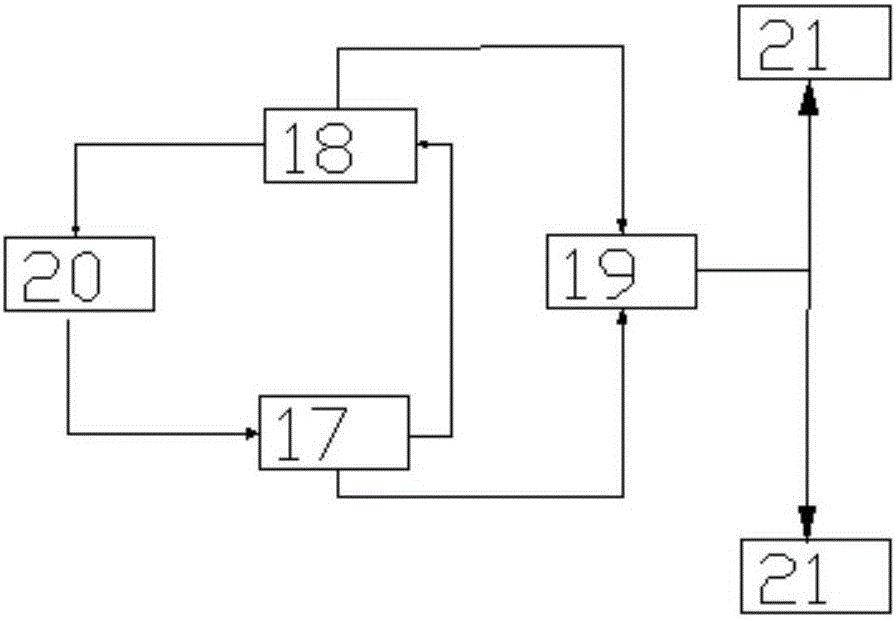

[0033] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 , figure 2 and image 3 Shown: the automatic pole vehicle for power transmission and wiring engineering of the present embodiment, which includes a vehicle frame 1, a control room 2, a drilling device 3, a pole device 4 and a rod pulling device 5, the control room 2, the drilling device 3. The pole device 4 and the lever device 5 are both arranged on the vehicle frame 1, on which the vehicle frame 1 is provided with a jack 6, and the control room 2 includes a cab 7 and a control room 8, and the bottom of the control room 8 is A slideway 9 is provided, the drilling device 3 includes a rotating disk 10 and a drilling arm 11, the vertical rod device 4 includes a planetary wheel 12 and a mechanical arm 13, and the rod pulling device 5 includes a rod pulling motor 14 and a storage rod box 15.

[0034] The vehicle frame 1 is provided with a driving device 16, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com