Formwork assembly system based on groove type rectangular pipes and construction technique

A technology of grooved and rectangular tubes, which is applied in the mold matching system and construction technology field based on grooved rectangular tubes, can solve the problems of increasing forest tree felling, uneven concrete surface, and labor-intensive labor, so as to shorten the construction period, The construction quality is easy to guarantee and the effect of reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

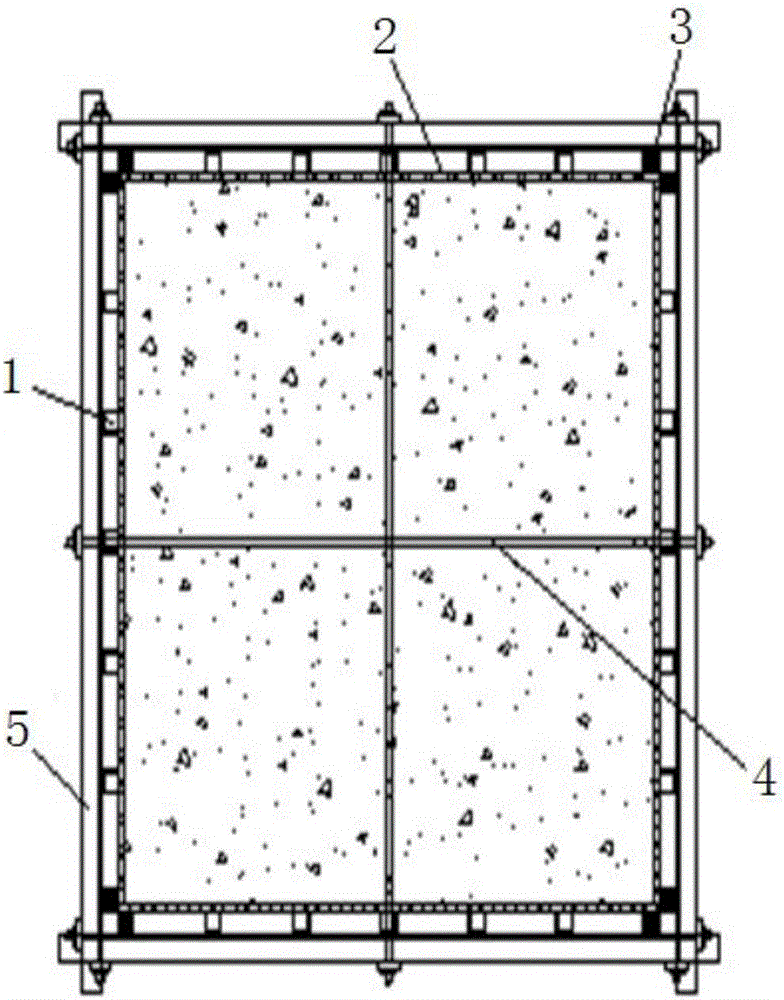

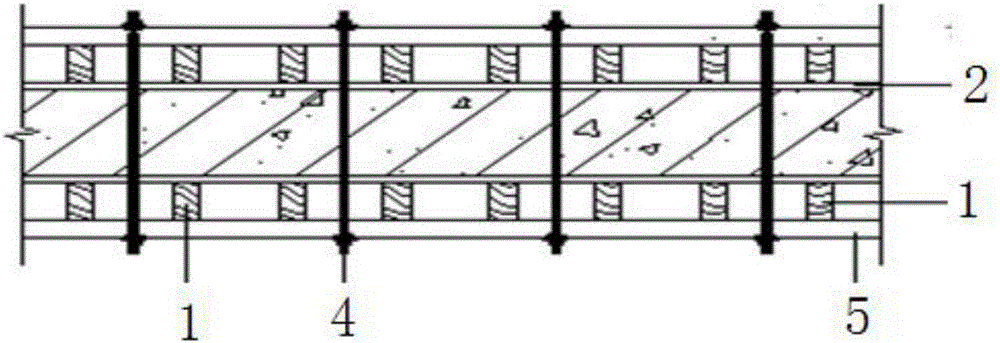

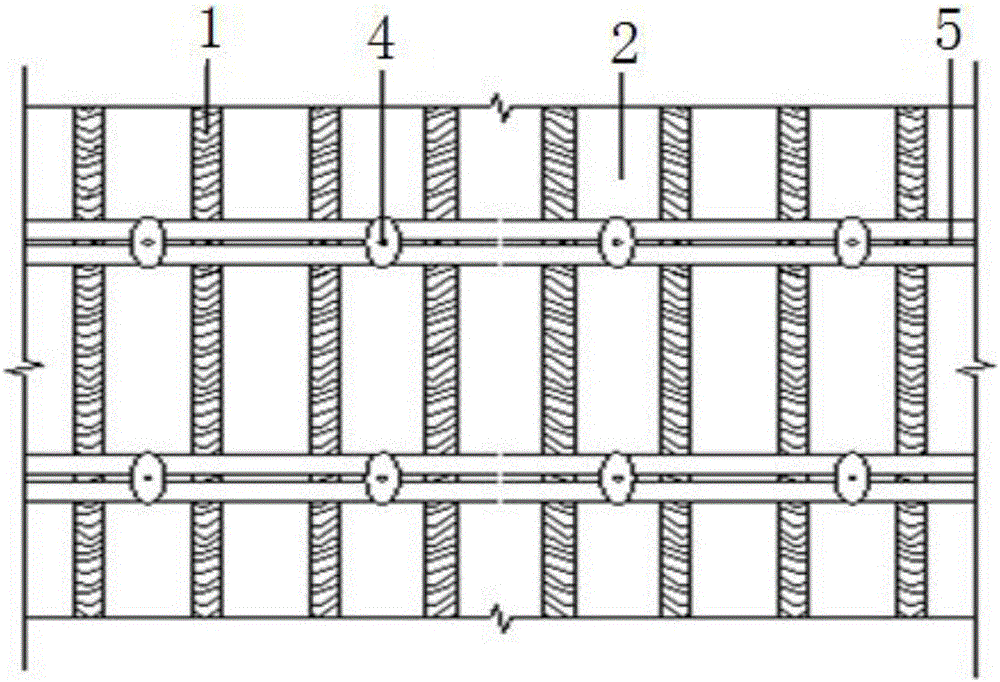

[0045] see Figure 1-5 , a mold matching system based on a grooved rectangular tube, including a column mold mechanism, a wall mold mechanism, a beam mold mechanism and a support mechanism; the column mold mechanism includes a grooved rectangular tube 1, a panel 2, a wooden square 3, The pull screw 4 and the main corrugated rib 5, the panels 2 are respectively arranged around the cylinder, the panels 2 form a square frame, the grooved rectangular tubes 1 are vertically arranged, and are evenly spaced outside the panel 2 along the horizontal direction , the wooden squares 3 are set at the four corners of the square frame formed by the panels 2, and the wooden squares 3 are parallel to the grooved rectangular tube 1, the main ribs 5 are arranged horizontally, and the main ribs 5 are evenly spaced along the vertical direction The wooden sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com