Small floor grout spreading all-in-one machine

An all-in-one machine and slurry spreading technology, which is applied in construction and building structure, etc., can solve the problems of low slurry spreading efficiency and increase the labor intensity of construction personnel, and achieve the effect of reducing labor intensity, reliable structure and improving the level of mechanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

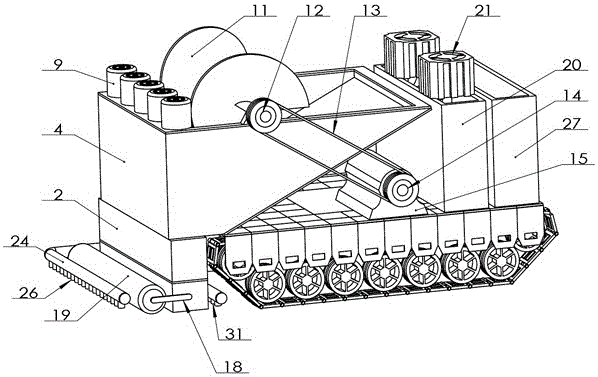

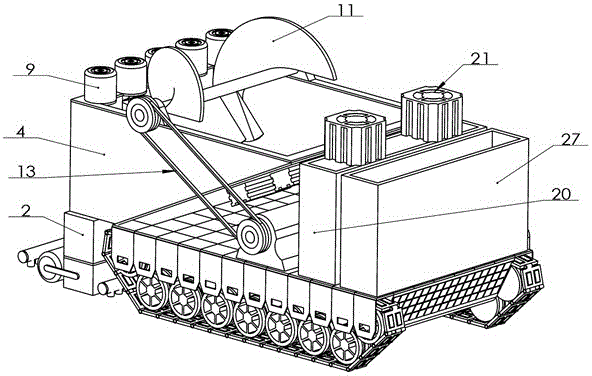

[0075] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 and Figure 22 As shown, a small-scale all-in-one floor grouting machine includes a crawler chassis 1, a front frame 2, a circular through hole 3, a hopper 4, a feeding plate 5, an extrusion motor fixing seat 6, a conveying tube 7, a belt Block bearing 8, extrusion motor 9, extrusion auger 10, stirring auger 11, driven pulley 12, belt 13, driving pulley 14, motor 15, extruder 16, tapered through hole 17, connecting rod 18, Drum 19, pulp box 20, stirring motor 21, agitator 22, pulp outlet 23, pulp delivery pipe 24, slurry delivery pipe control valve 25, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com