Lateral-clamping vibration hammer

A vibratory hammer and side clamping technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the difficulty of picking up piles, affect the flexibility and stability of excavator piling, and make it difficult for the clamping device to lie down on the pile and problems such as driving inclined piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

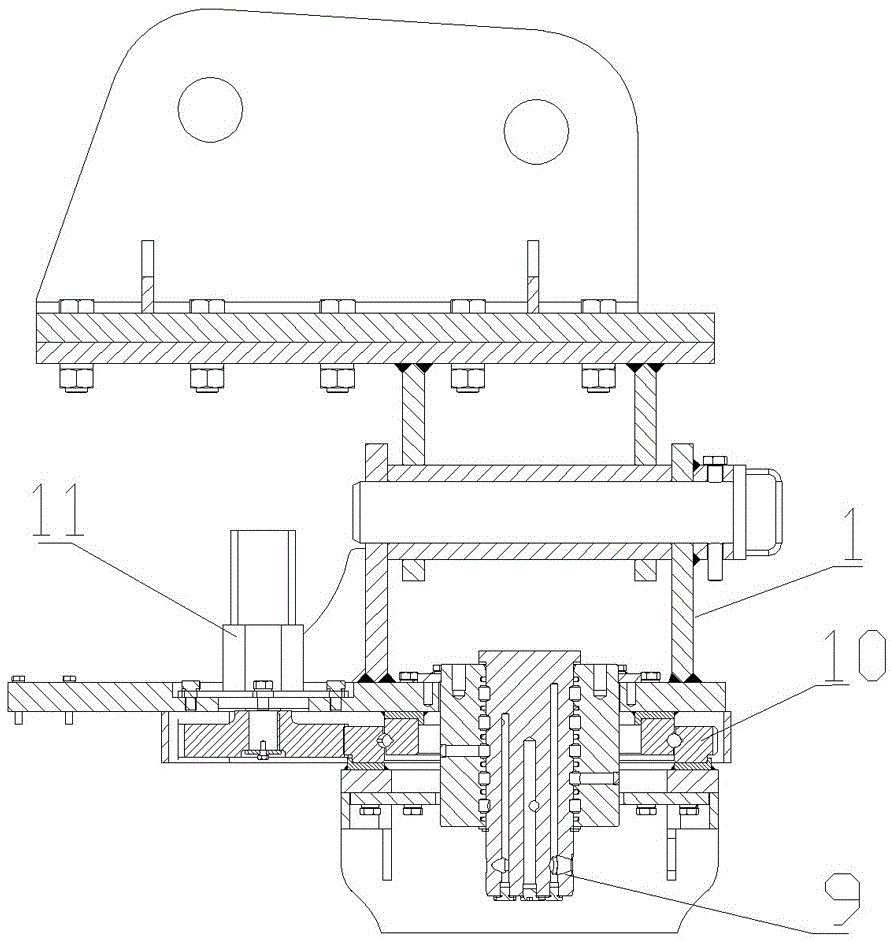

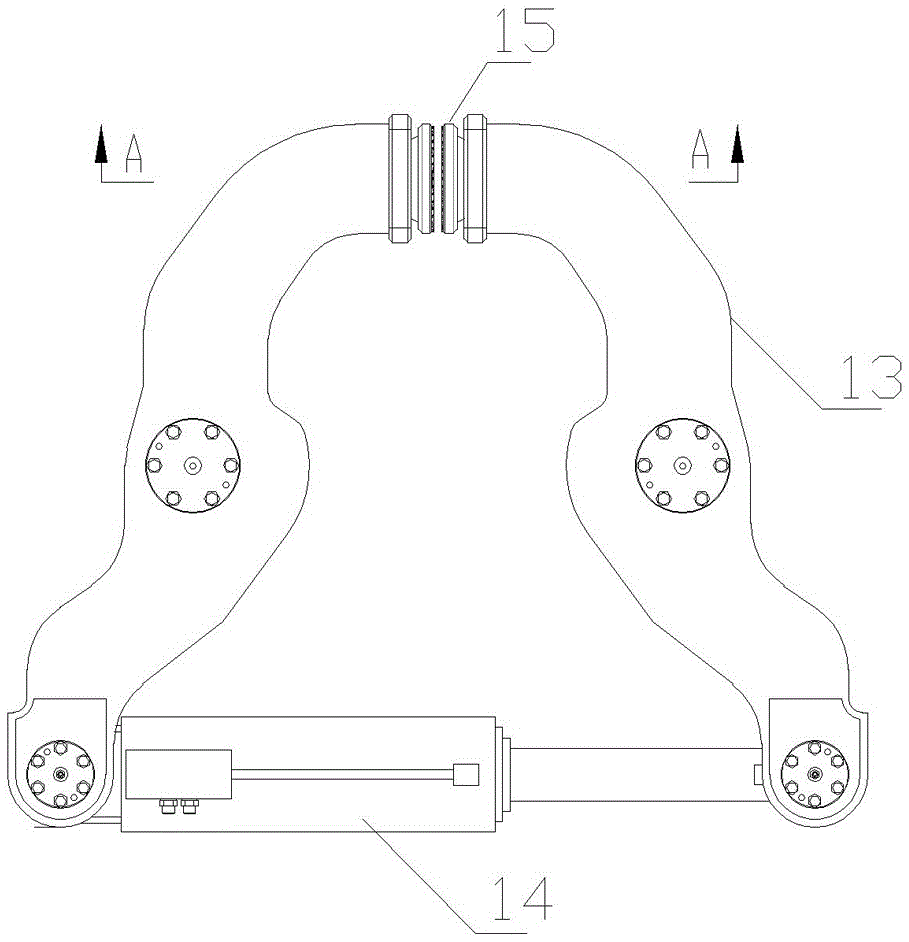

[0017] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. This side clip vibratory hammer comprises vibrating device 1, clamping device 2, hoisting device 3 and control system, and hoisting device comprises the structure such as boom as prior art, and control system can be programmable logic controller PLC, and described vibrating device 1 is connected with the clamping device 2, the clamping device 2 and the vibrating device 1 are arranged in the vibration damping device 4, the vibration damping device 4 includes an outer frame 5 and a rubber spring 6 arranged on the inner wall of the outer frame 5, the rubber spring 6 is connected with the vibration box 7, the vibration box 7 is used to install the vibration device 1, a rotating body 8 is arranged above the vibration damping device 4, and a central rotary joint 9 and a rotating body are connected between the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com