A magnesium oxide spray gun

A magnesium oxide and spray gun technology, applied in the field of magnesium smelting industry, can solve the problems of easy damage to the vacuum environment of the vacuum melting furnace and low work efficiency, and achieve the effects of low cost, convenient installation and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

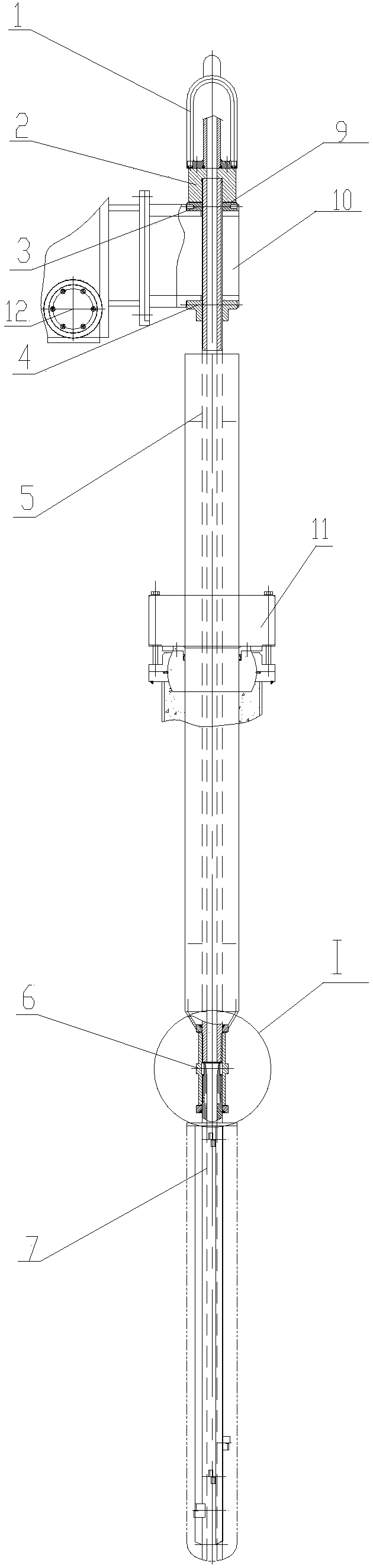

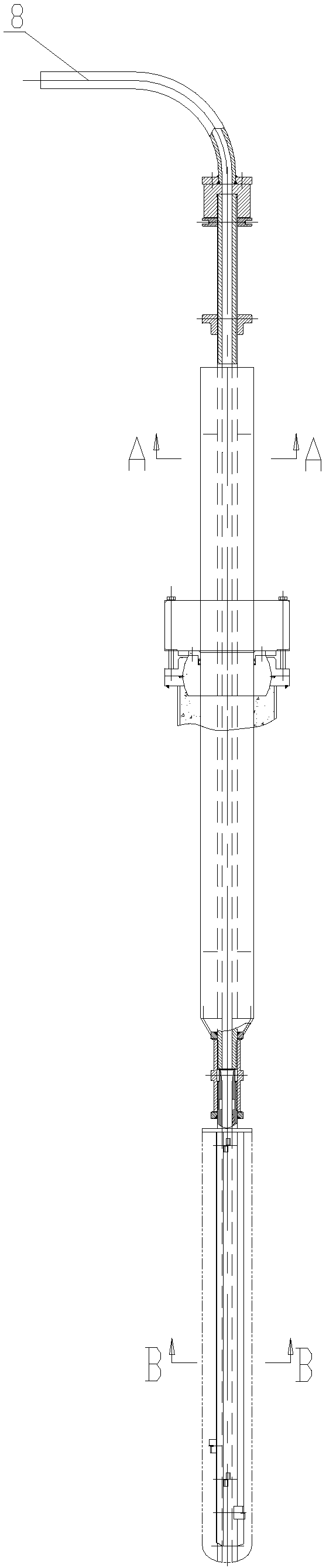

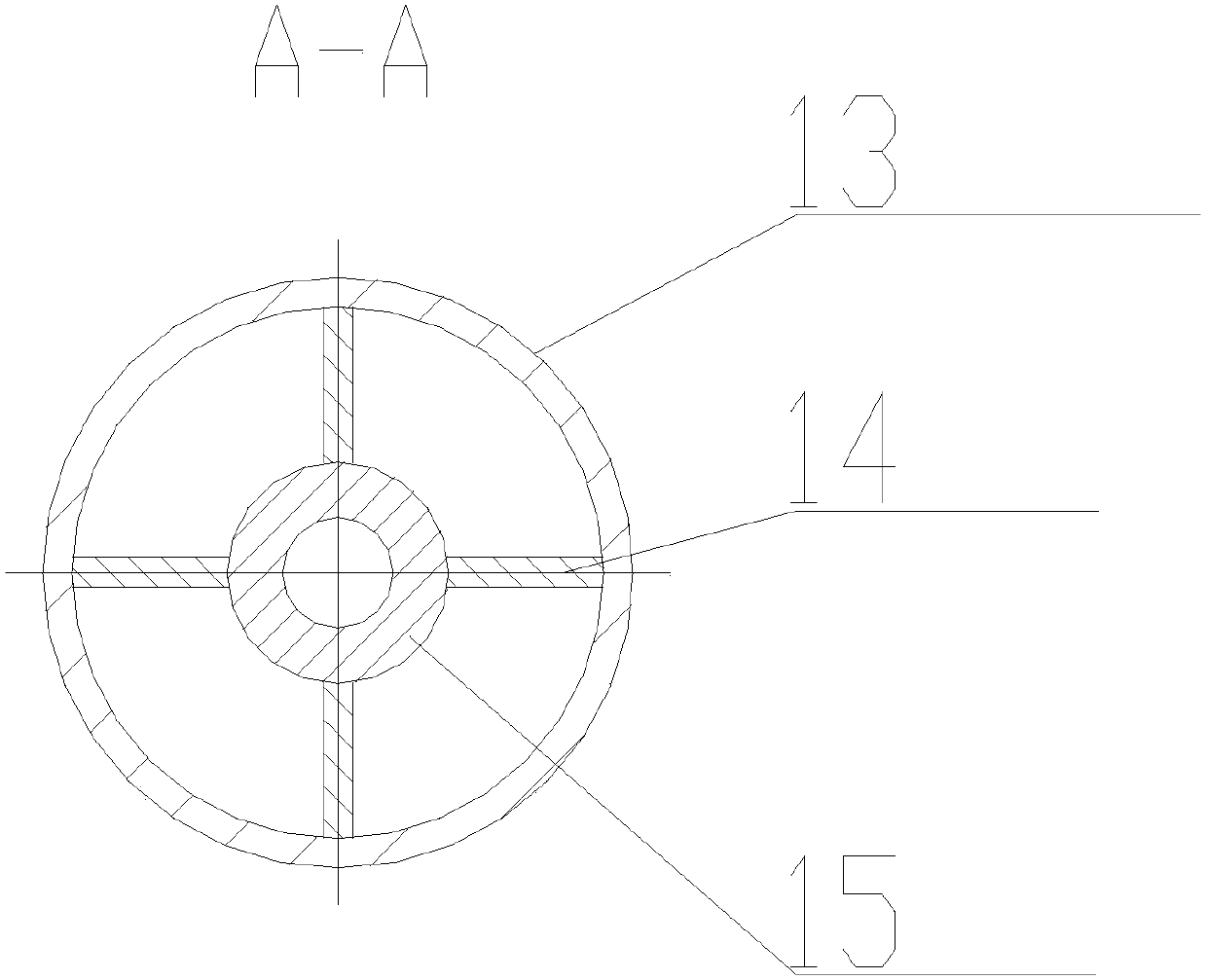

[0012] from figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the present invention is from top to bottom from the top suspension ring 1, the cylindrical joint body 2, the sealing nut 3, the locking nut 4, the tubular upper gun body 5, the connecting nut 6, the tubular lower gun body 7, the connecting bend Tube 8 is composed. The suspension ring 1 is connected together with the upper part of the joint body 2 by bolts. The upper gun body 5 includes an upper spray gun tube 15. The upper and lower surfaces of the upper spray gun tube 15 are all provided with threads, and the top of the upper thread is screwed into the bottom of the joint body 2. At the same time, the upper thread is equipped with a sealing nut 3 and a locking nut 4, and a sealing gasket 9 is placed between the sealing nut 3 and the bottom of the joint body 2 to play a sealing role and prevent leakage. The outer surface of the upper spray gun tube 15 is covered with a long section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com