Integrated primary explosive production line, and workshop plane layout structure thereof

A technology of plane layout and priming charge, which is applied in the direction of detonators, industrial buildings, offensive equipment, etc., can solve the problem of small space and achieve the effects of quantity reduction, safety performance guarantee and ideal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

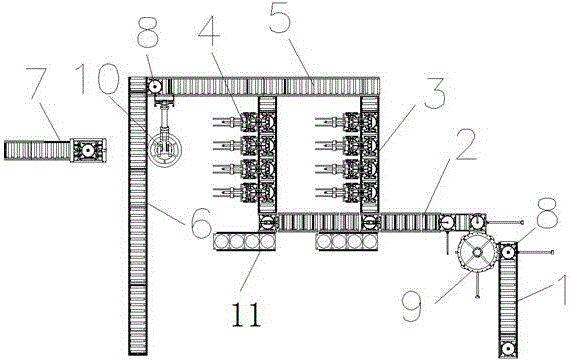

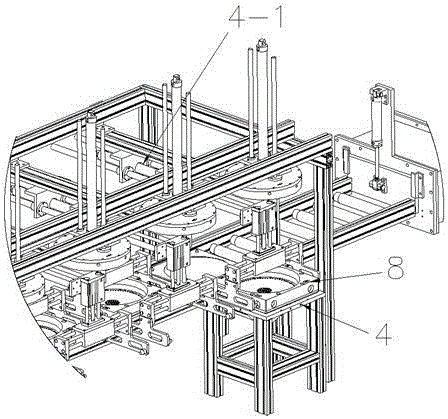

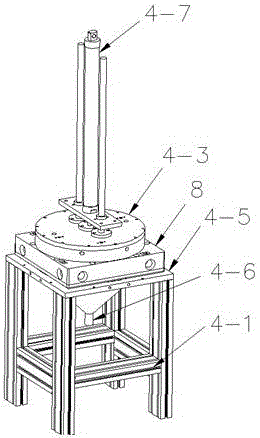

[0017] Embodiments of the present invention: an integrated primary explosive production line, including a medicine tray conveyor 1, a medicine tray transfer machine 2 is arranged at the end of the medicine tray conveyor 1, and the delivery direction of the medicine tray transfer machine 2 is the same as that of the medicine tray conveyor 1. Vertical, between the medicine tray conveyor 1 and the medicine tray transfer machine 2, there is a sub-disc suction and filtration device 9, and the conveying connection is realized through the cylinder push plate; two medicine drying conveyors are arranged on one side of the medicine tray transfer machine 2 3. The conveying direction of the medicine drying conveyor 3 is perpendicular to the medicine tray transfer machine 2. The medicine tray transfer machine 2 and the medicine drying conveyor 3 are connected by a manipulator. There is a medicine drying and cooling device 4; the other side of the medicine tray transfer machine 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com