Artificial stone and preparation method thereof

An artificial stone and limestone technology, applied in the field of artificial stone and its preparation, can solve the problems of polluting the environment, high manufacturing cost, high energy consumption, etc., and achieve the effects of wide distribution, energy saving and soil resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

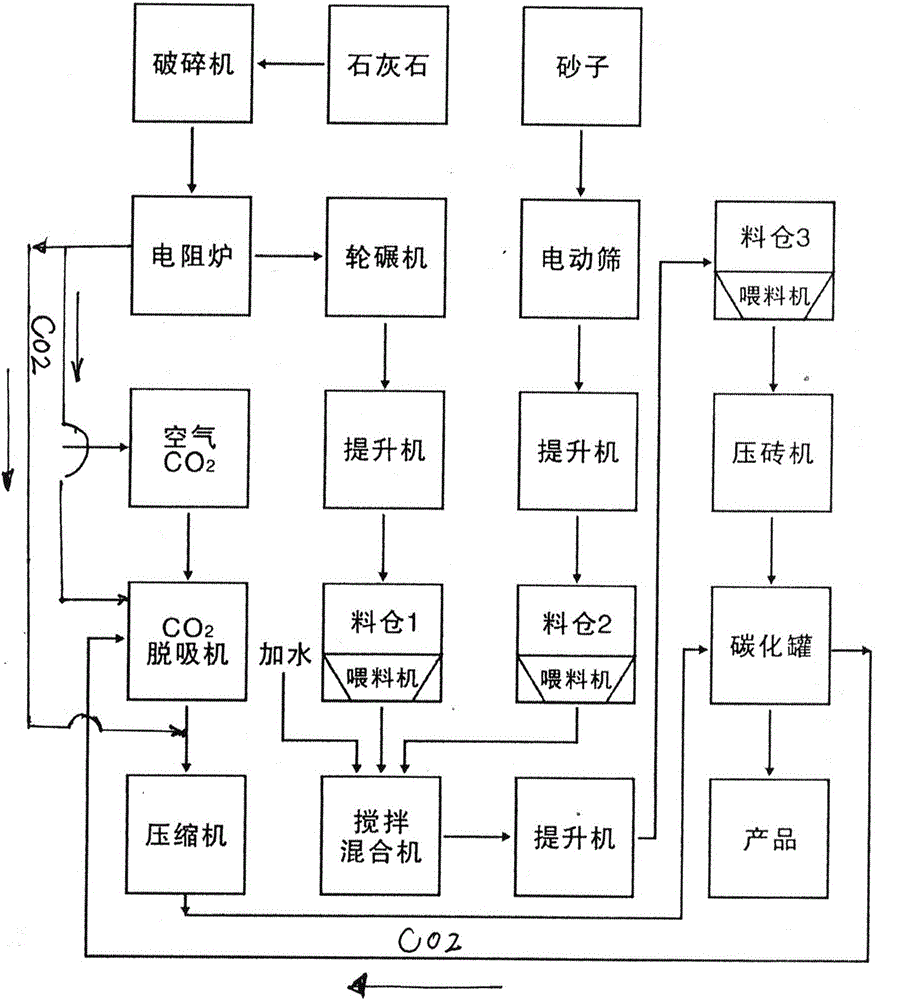

[0025] A method for preparing artificial stone, comprising the steps of:

[0026] 1. Crush the large limestone to 40-50 mm, send it to the resistance furnace with a bucket elevator, bake and modify half-baked and slightly oxidized with CO 2 After discharge, stop the furnace and cool down, manually push it into the wheel mill, then crush it to 5-10mm, and transport it to the silo for preparation by elevator.

[0027] 2. The sand is loaded and transported from the sand storehouse by the dump truck to the bucket elevator, and then transported to the silo for material preparation. The sand particle size is 0.2-1.0mm.

[0028] 3. Use the disc feeder at the lower part of the limestone and sand silos to adjust the ratio of sand and limestone to a weight ratio of 100:5-10, and then send it to the mixing mixer for mixing operation until it is uniform. Water is added to moisten and discharge the material when it is sticky, and it is lifted by the bucket elevator to the silo of the bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com