Passivation treatment process for cylinders of electronic grade arsine, phosphine and their mixture gases

A gas cylinder, passivation treatment technology, applied in the direction of phosphine, arsenic/antimony hydride, metal hydride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

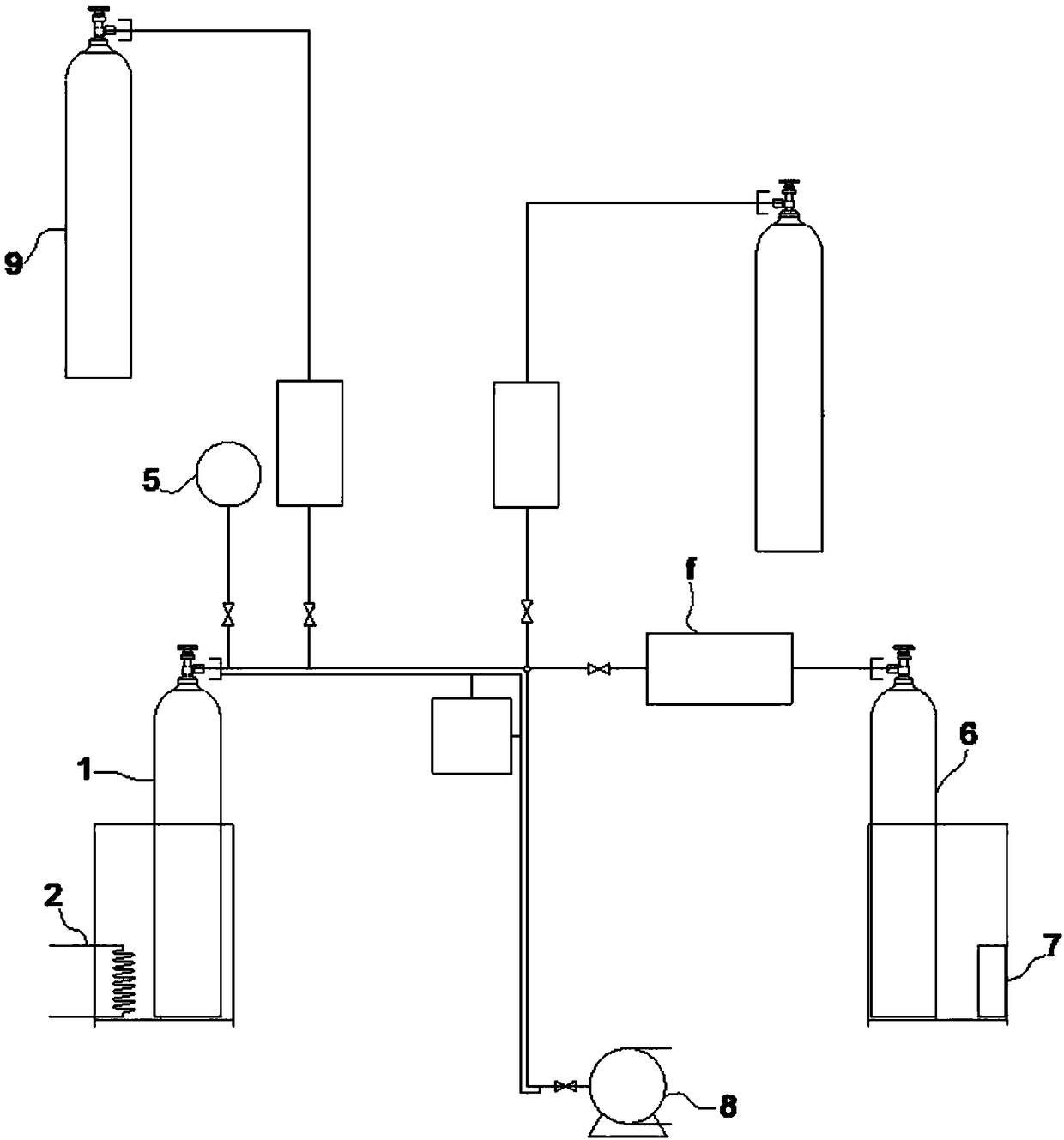

[0017] With reference to accompanying drawing, a kind of passivation treatment process of electronic grade arsine, phosphine and its mixture gas steel cylinder is characterized in that, comprises the following steps:

[0018] 1) heating and baking the first steel cylinder 1 to be passivated at a high temperature of 100-200°C;

[0019] 2) Vacuumize the first steel cylinder 1 through the exhaust fan 8, and continue to heat and bake the first steel cylinder 1 at a temperature of 100-200°C. 3) Purging replacement: when the first steel cylinder 1 is pumped to a vacuum state , filling the first steel cylinder 1 with nitrogen or hydrogen or an inert gas by displacing the gas cylinder 9, and continuously heating and baking the first steel cylinder 1 at a temperature of 100-200°C;

[0020] 4) Vacuumize the first steel cylinder 1 through the exhaust fan 8, and continue to heat and bake the first steel cylinder 1 at a high temperature of 100-200°C. The whole process of this step controls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com