Driving cab rollover protection mechanism

A technology for protecting the mechanism and the cab, applied to the superstructure, the superstructure of the truck, transportation and packaging, etc., can solve the problems of the cab turning out of control, casualties, falling off, etc., to avoid the failure of the limit structure and reduce the cost Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

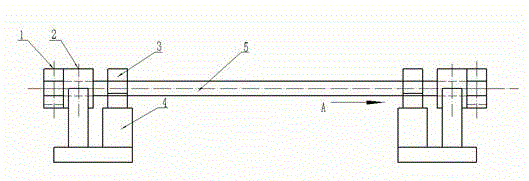

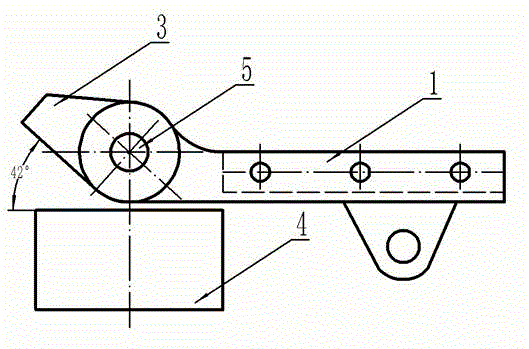

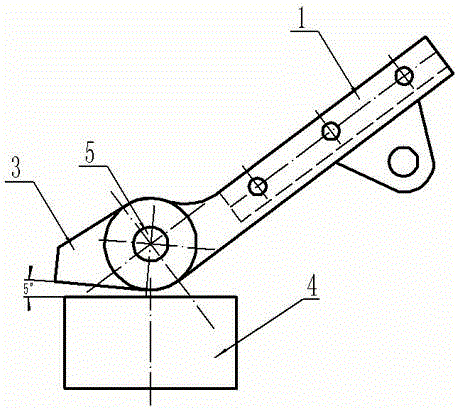

[0015] like figure 1 and figure 2 As shown, a cab overturning protection mechanism includes a lift cylinder connecting arm 1 connected to the cab longitudinal beam, and a turning torsion bar 5, and the connecting arm 1 and the turning torsion bar 5 are connected by welding. The two ends of the overturning torsion bar 5 are respectively provided with a suspension lower support 2, the overturning torsion bar 5 can rotate through the suspension lower support, the suspension lower support 2 is fixed on the vehicle frame by bolts or welding, and the overturning torsion bar Both ends of 5 are provided with a limit arm 3, and the limit arm 3 is fixed on the turning torsion bar 5 through a spline connection or welding; each suspension lower support 2 is provided with a limit block 4 corresponding to the limit arm 3 , the limit block 4 and the suspension lower support 2 are of an integrated structure, and are made by casting; after the limit arm 3 is turned over, the angle formed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com