Pretreatment device of refrigeration house door plate

A pretreatment device and door panel technology, applied in static electricity, metal processing, electrical components, etc., can solve the problems of high work intensity, low work efficiency, cold storage door panel coating and cutting backward, etc., to achieve high production efficiency and improve cutting quality , Reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

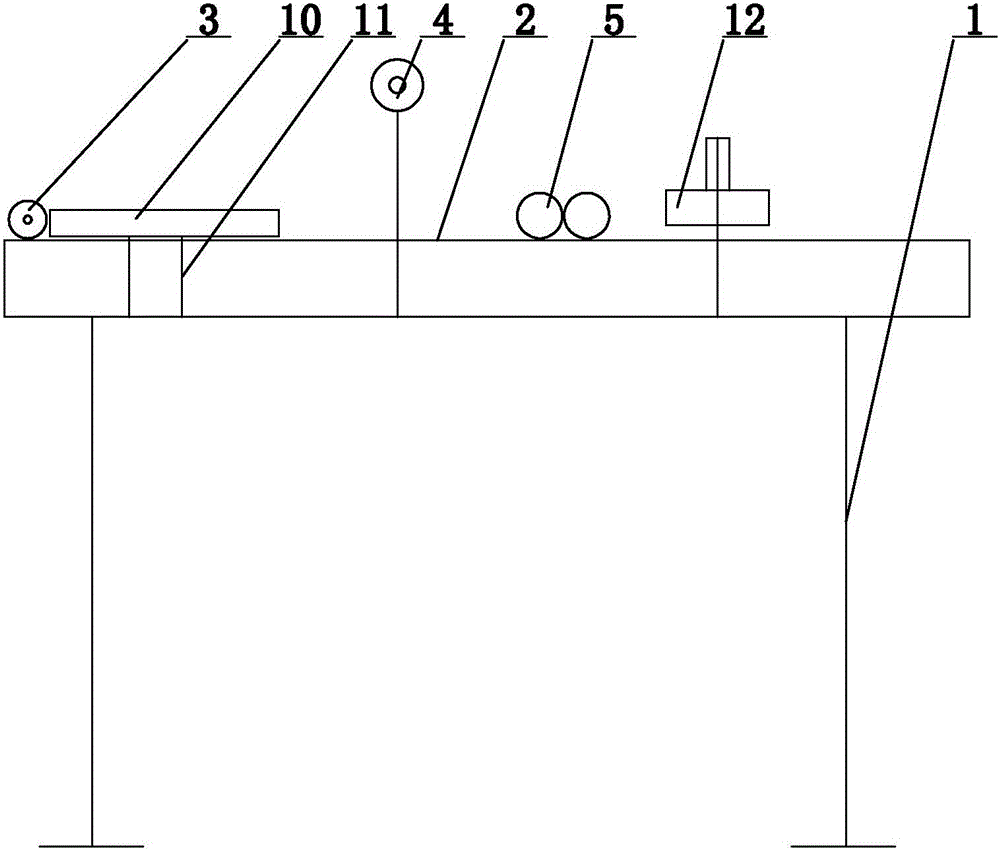

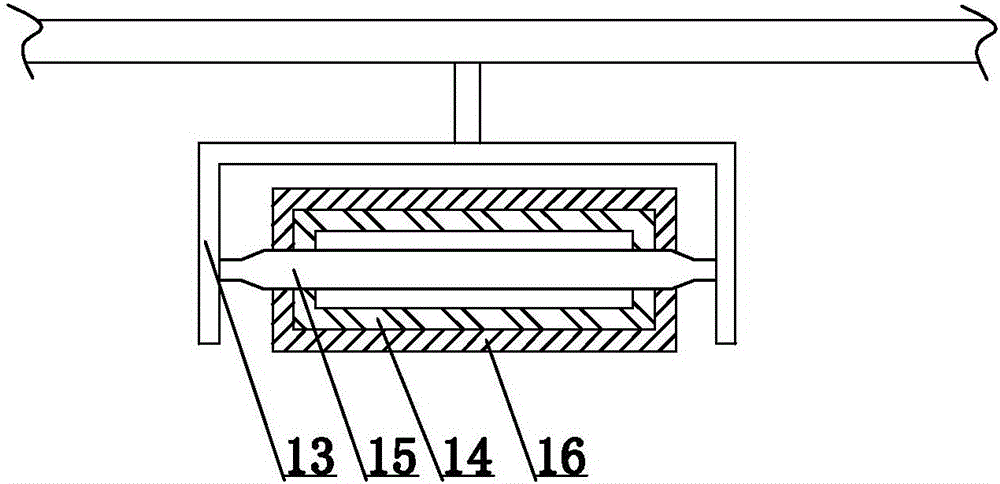

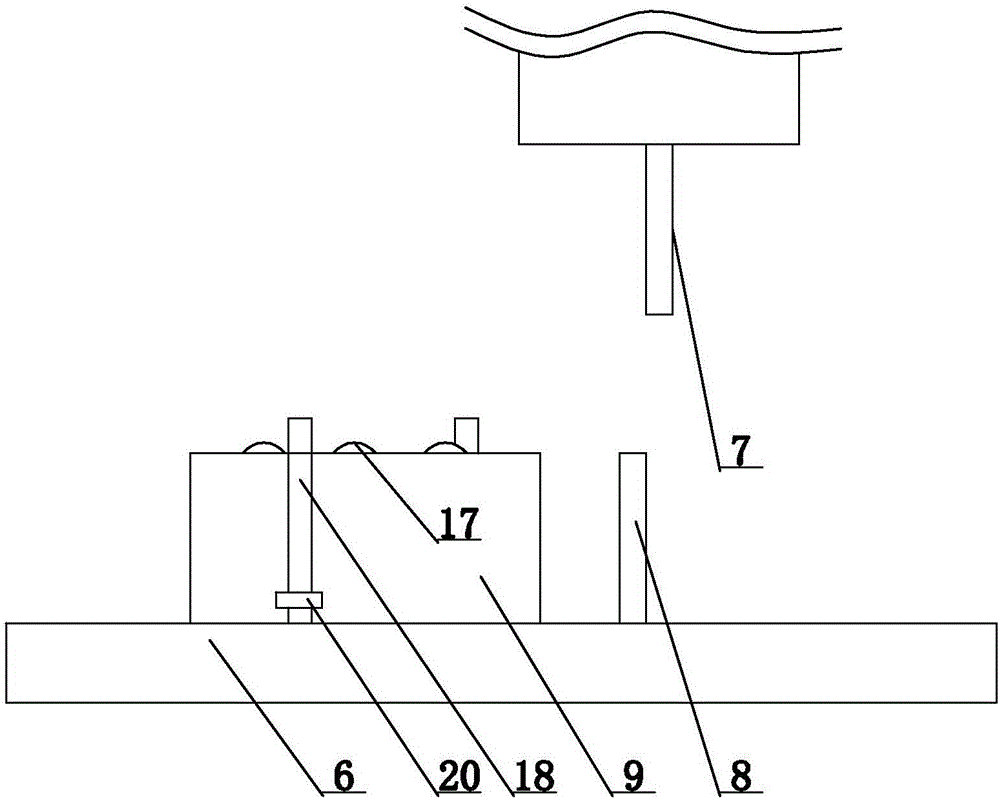

[0023] Such as figure 1 , image 3 and Figure 4 As shown, the cold storage door panel pretreatment device described in this embodiment includes a film-coating station and a cutting station arranged in sequence, and the film-coating station includes a film-coating frame 1, and the film-coating frame 1 is set Conveyor belt 2, the starting end of conveyor belt 2 is provided with a flattening roller 3 corresponding to the door panel, a lamination roller 4 is provided above the middle position of the conveyor belt 2, and a cutting station is provided at the other end of the conveyor belt 2, and the lamination roller 4 and the cutting station are arranged in sequence Laminating roller 5 and destaticizing mechanism 12 are set; The cutting station includes a cutting platform 6 and at least one set of cutting knives, and the cutting knives include an upper cutting knife 7 and a lower cutting knife 8 arranged oppositely, and the upper cutting knife 7 Connect drive unit 1, on the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com