Split-type ratchet wrench

A ratchet wrench, split-type technology, applied in the field of wrenches, can solve problems such as the inability to screw and disassemble threaded connectors in closed systems, and achieve the effects of improving operational safety, avoiding bad force effects, and avoiding easy slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

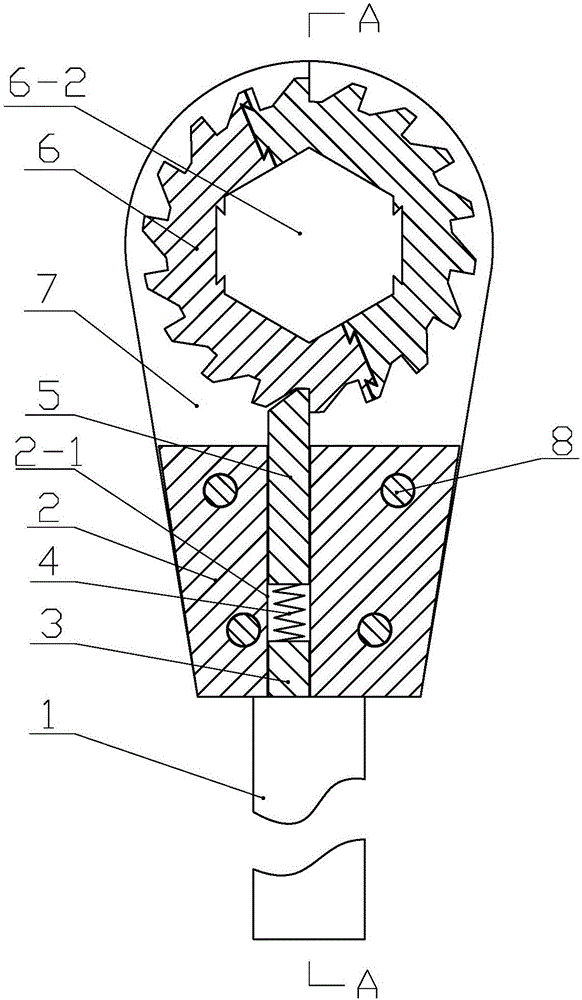

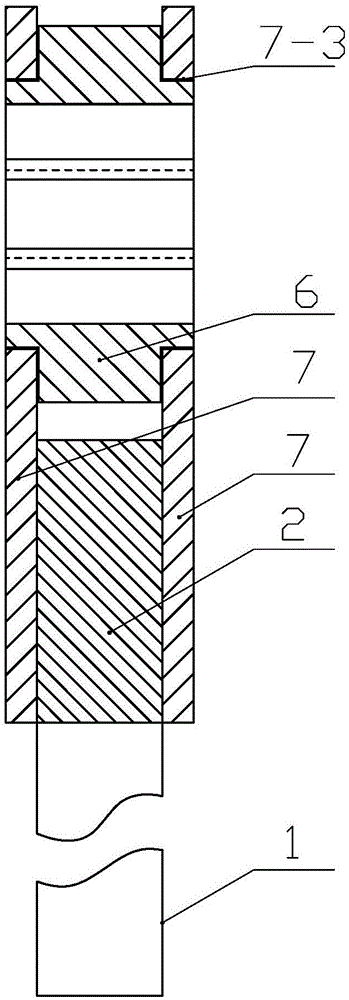

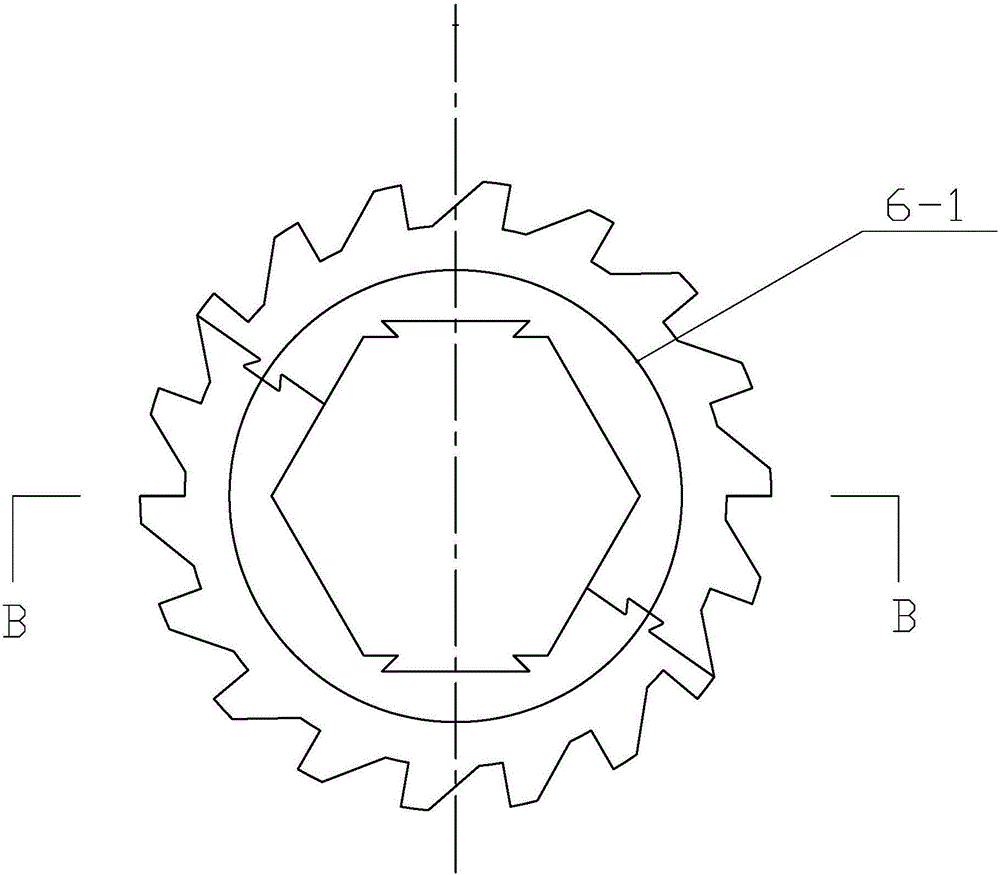

[0021] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, a split type ratchet wrench of this embodiment, including a handle 1, a fixed core 2, a plug 3, a spring 4, and a pawl 5, one end of the handle 1 is fixedly connected to one end of the fixed core 2, the The inside of the fixed core 2 is provided with a first through hole 2-1, the axis of the first through hole 2-1 is arranged parallel to the axis of the handle 1, and the plug 3 and the spring 4 are installed on the bottom of the fixed core 2 sequentially from bottom to top. In the first through hole 2-1, one end of the ratchet 5 is in contact with one end of the spring 4, and the other end surface of the ratchet 5 is an inclined plane. It also includes a split ratchet 6 and a two-component split positioning plate 7. The one-piece ratchet 6 includes two half-wheels 6-1 connected head to tail through the dovetail chute, and the center of the split-type ratchet 6 is provided with a fi...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 1 to Figure 5 To illustrate this embodiment, the split ratchet 6 is positioned above the ratchet 5 through the two-component positioning plate 7 , and the hubs of the split ratchet 6 are in clearance fit with the two second through holes 7 - 3 . In such a design, the arc-shaped groove 7-2 mainly serves to limit the radial position of the ratchet to realize the rotation of the ratchet around the ratchet axis. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 , image 3 and Figure 9 To illustrate this embodiment, a split type ratchet wrench also includes a split type inner sleeve 9, and the split type inner sleeve 9 includes two half sleeves 9-1 that are in close contact with each other. The first polygonal through hole 6-2 of the ratchet 6 cooperates, and the split inner sleeve 9 is fixedly connected in the first polygonal through hole 6-2 through the dovetail chute, and the center position of the split inner sleeve 9 is along its A second polygonal through hole is opened in the axial direction. With this design, split inner sleeves 9 of corresponding sizes can be nested according to different sizes of threaded connectors (such as nuts) during use, so that the same ratchet wrench can be used to assemble and disassemble threaded connectors of different sizes, effectively reducing Tool kit storage space saves cost and improves work efficiency. The outline of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com