Welding pliers capable of protecting welded line joint

A wire joint, shielded welding technology, applied in the direction of electrode characteristics, electrode support devices, etc., can solve problems such as unstable contact and frequent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

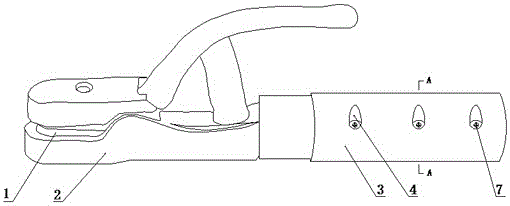

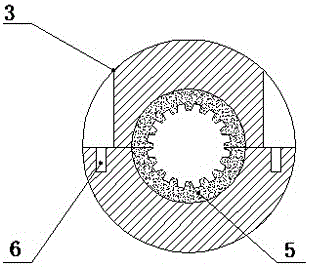

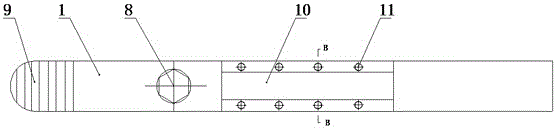

[0015] figure 1 It shows a welding tongs capable of protecting welding wire joints provided by the present invention, including a welding handle 3, a welding tongs body 2 and a terminal post 1 embedded in the welding tongs body 2, the welding tongs 3 are cylindrical, and the welding tongs 3 adopts an upper and lower split structure, and the appearance of the welding handle 3 is cylindrical, and the upper and lower split structure divides the welding handle 3 into two parts that are equal up and down. The structural shape is similar to a small cylindrical surface vertically intersecting with the welding handle 3, and the upper and lower parts of the welding handle 3 are fixedly connected by screws 7, and the screws 7 are arranged in the counterbore 4, such as figure 2 As shown, and cooperate with the screw hole 6 arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com