Sealant dispersing system with circulating water temperature adjusting device

A technology of a temperature adjusting device and a dispersing system, applied in the field of dispersing machines, can solve the problems of inability to adjust the temperature of the sealant, low efficiency, and time-consuming dispersing operations of dispersing machines, so as to accelerate mutual dispersing, improve production efficiency, and shorten dispersing operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

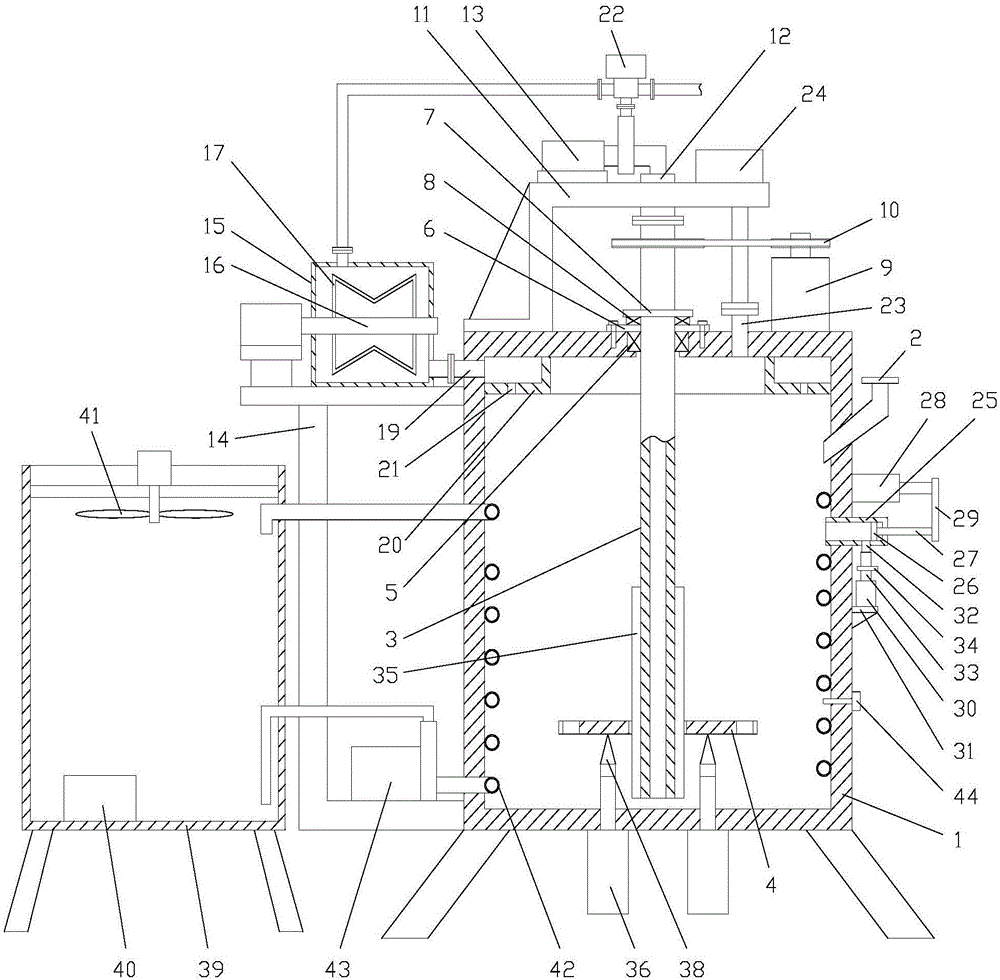

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] As shown in the figure, the sealant dispersing system with a circulating water temperature regulating device in this embodiment includes a cylindrical main container body 1 and a feed inlet 2 arranged on the main container body;

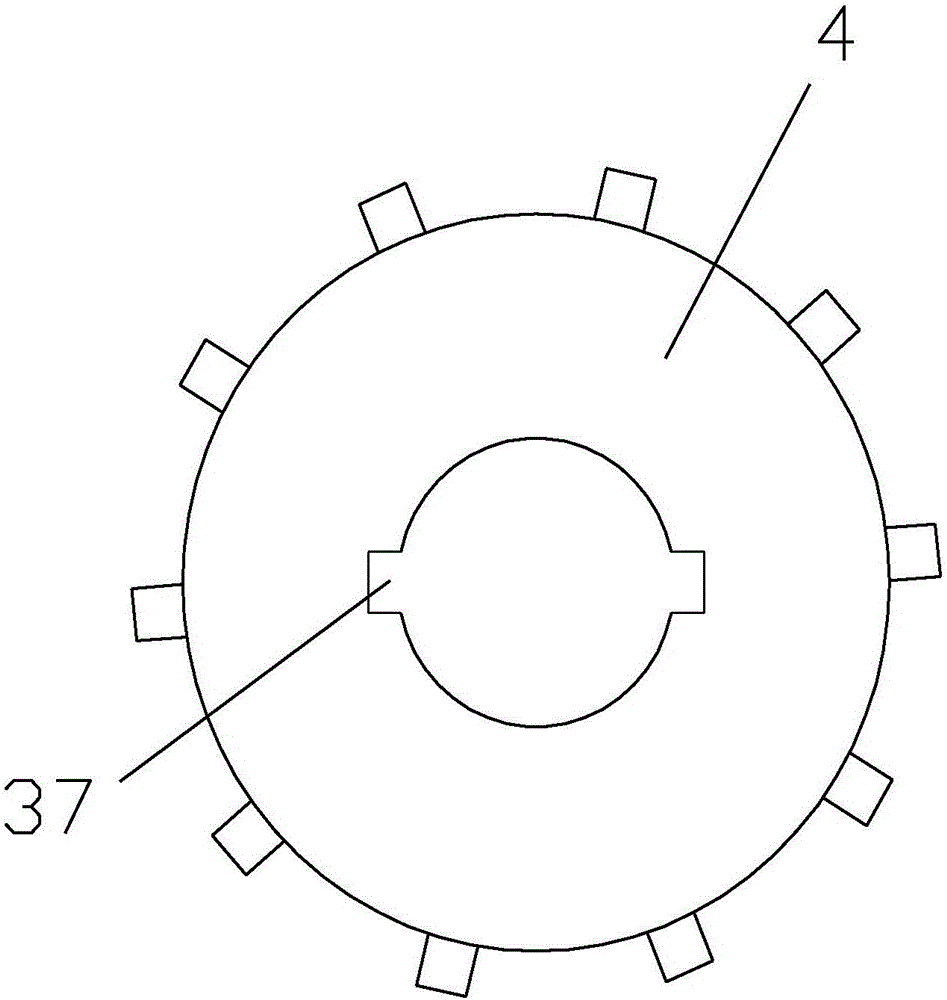

[0030] It also includes a vertical stirring shaft 3 arranged in the middle of the cylindrical main container body, the vertical stirring shaft is hollow tubular, and a stirring knife 4 is arranged on the vertical stirring shaft;

[0031] The main container body is provided with a rolling bearing 5 that rotates with the vertical stirring shaft and a bearing cap 6 that fixes the rolling bearing on the container. The vertical stirring shaft is provided with an annular flange 7, and the bearing cap is provided with a There is a planar thrust bearing 8 supported under the annular flange;

[0032] It also includes a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com