Tea pan-frying device

A technology for frying green and equipment, applied in the field of tea frying equipment, can solve the problems of applicability and practicability, deformation or crushing of tea leaves, and easy sticking on the frying board, etc. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

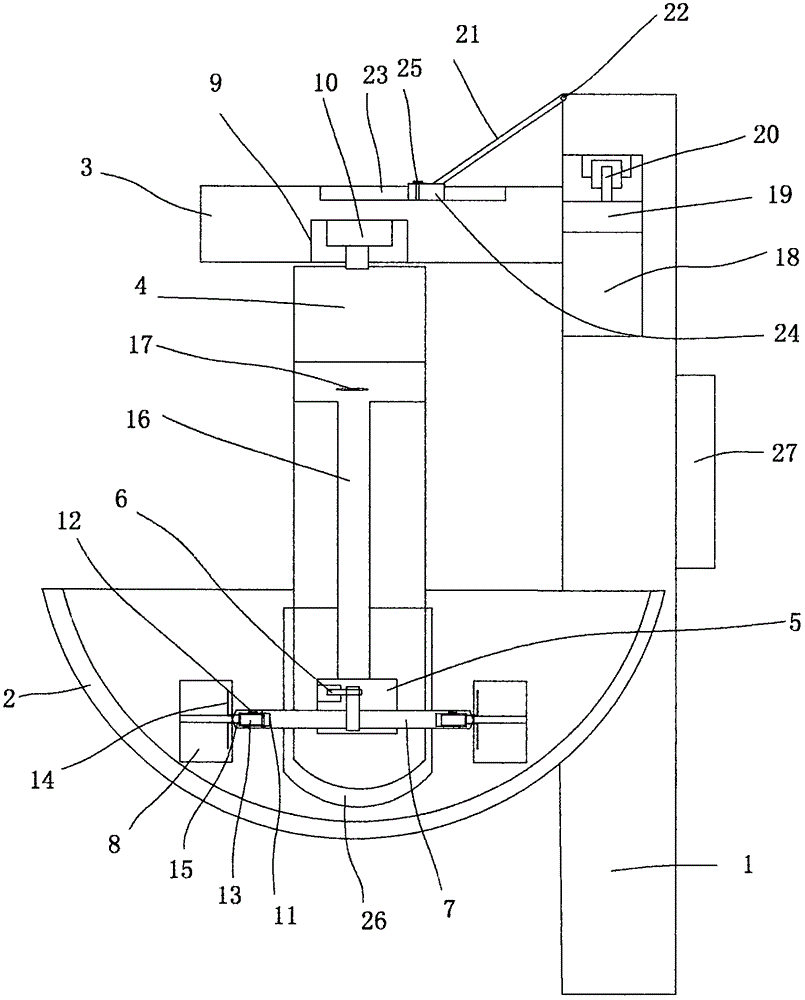

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a kind of equipment for frying green tea, comprising a support 1 and a frying pan 2 arranged on the support 1, a transverse strut 3 is also provided on the top of the support 1, and a direction to The pole 4 that extends down, the bottom end of described pole 4 stretches in the described frying pan 2, is also provided with cavity 5 at the bottom of described pole 4, is provided with turning over in described cavity 5 Stir-fry motor 6, also be provided with transverse axle bar 7 at the bottom end of described mast 4, described transverse axle bar 7 passes through described cavity 5 and the middle part of transverse axle bar 7 and the main shaft of described frying motor 6 connected, a cross-shaped frying plate 8 is provided at both ends of the transverse shaft 7, a rotating cavity 9 is provided in the transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com