Wavy silkworm cocooning tool

A wavy, silkworm technology, applied in animal husbandry and other directions, can solve the problems of poor ventilation, short service life and high cost, and achieve the effects of cheap and easy-to-obtain materials, enhanced ventilation, and cheap materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

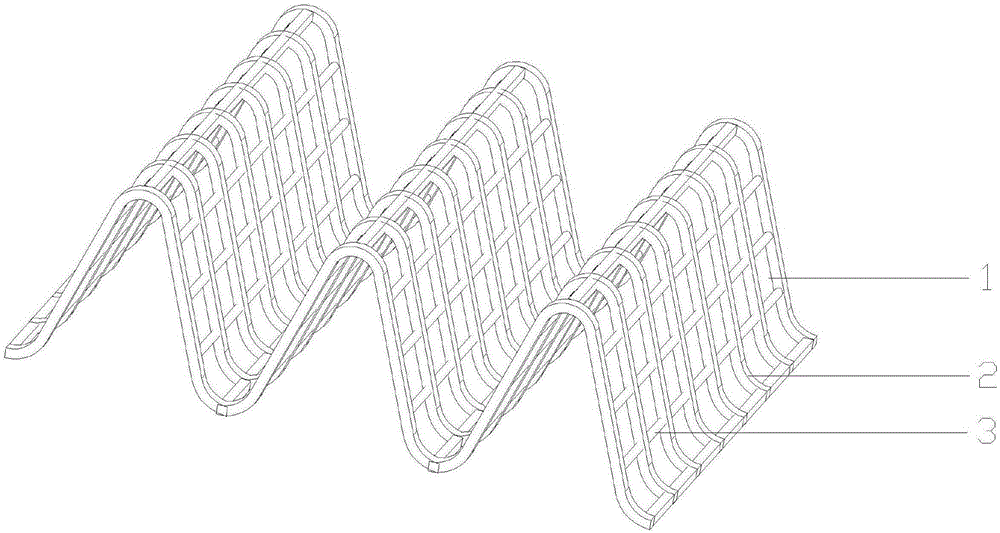

[0013] Such as figure 1 A wave-shaped cocooning tool for silkworms is shown, including: a frame made of plant biomass made by molding. Camp cocoon grid 1 of the same size, camp cocoon grid 1 is polygonal. At present, the camp cocoon lattice 1 is located on the same plane and the opening is upward, and most of the air circulates horizontally, so the ventilation of most products is extremely poor. However, the present invention adopts a wave-shaped structure, so that the air that circulates horizontally is also The energy flows into the cocoon grid 1 to ensure the appropriate temperature and humidity of the cocoon grid 1, which is conducive to improving the quality of the cocoon. The structure of the cocoon-making grid 1 of the present invention is reasonable, and the more commonly used ones such as rhombus-shaped or rectangular cocoon-making grids 1 are horizontal cocoons. As we all know, the quality of horizontal cocoons is better than that of other forms of cocoons. This str...

Embodiment 2

[0016] Such as figure 1 A wave-shaped cocooning tool for silkworms is shown, including: a frame body made of plant biomass material and molded. There are several cocoon grids 1 of the same size, and the cocoon grids 1 are polygonal. The invention is made by mold forming technology, which can be mass-produced and has low production cost.

[0017] In this embodiment, the partition is also made of plant biomass material.

[0018] In this embodiment, the separation strip includes several side strips 2 arranged along the direction of wave extension, and also includes several ribs 3 intersecting with the side strips 2 .

Embodiment 3

[0020] The material of a wavy silkworm cocooning tool comprises: plant biomass, adhesive, flame retardant and calcium carbonate. The material is inexpensive, low-carbon and environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com