Automatic leveling orchard comprehensive operation platform for hilly area

A work platform, automatic leveling technology, used in agriculture, non-electric variable control, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

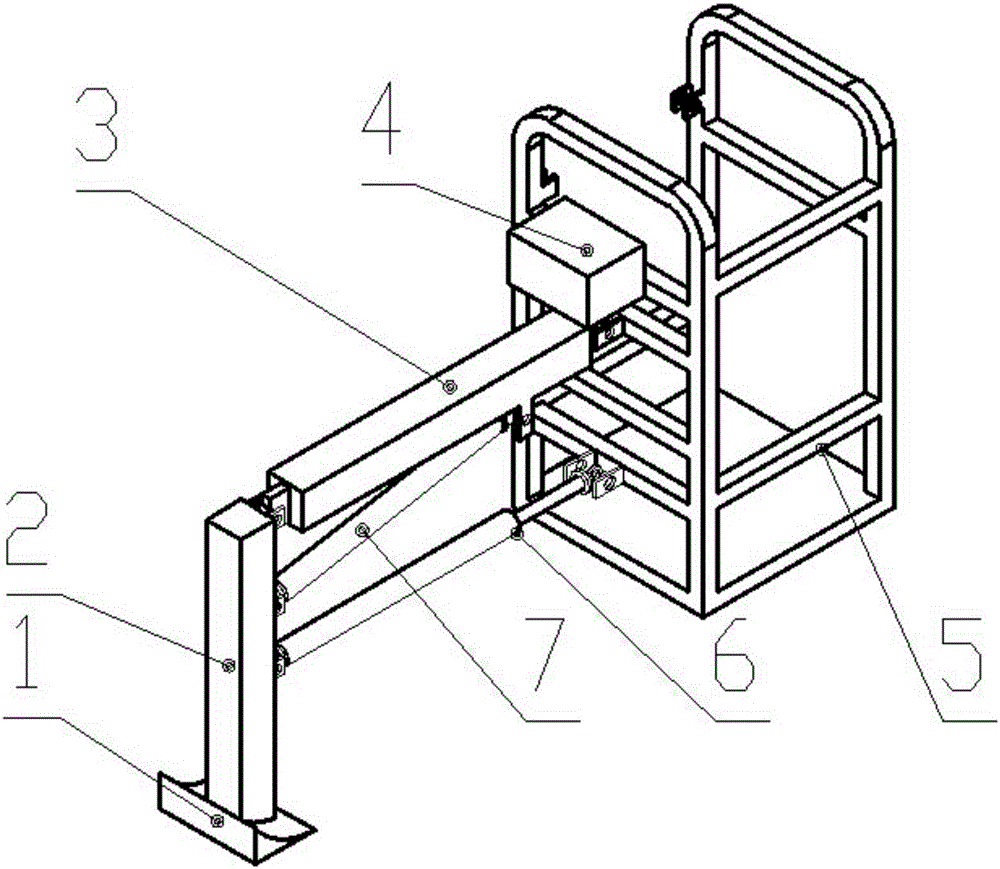

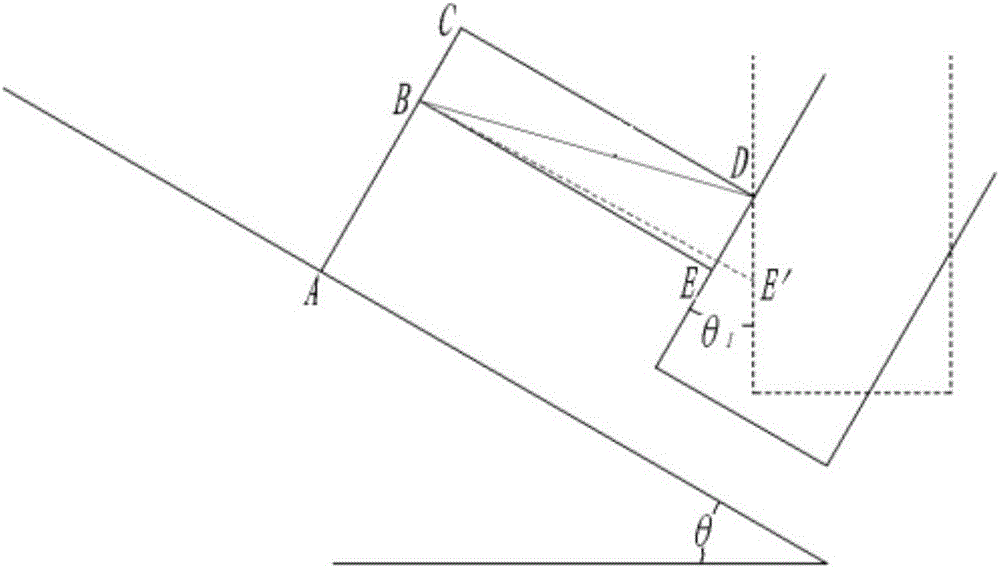

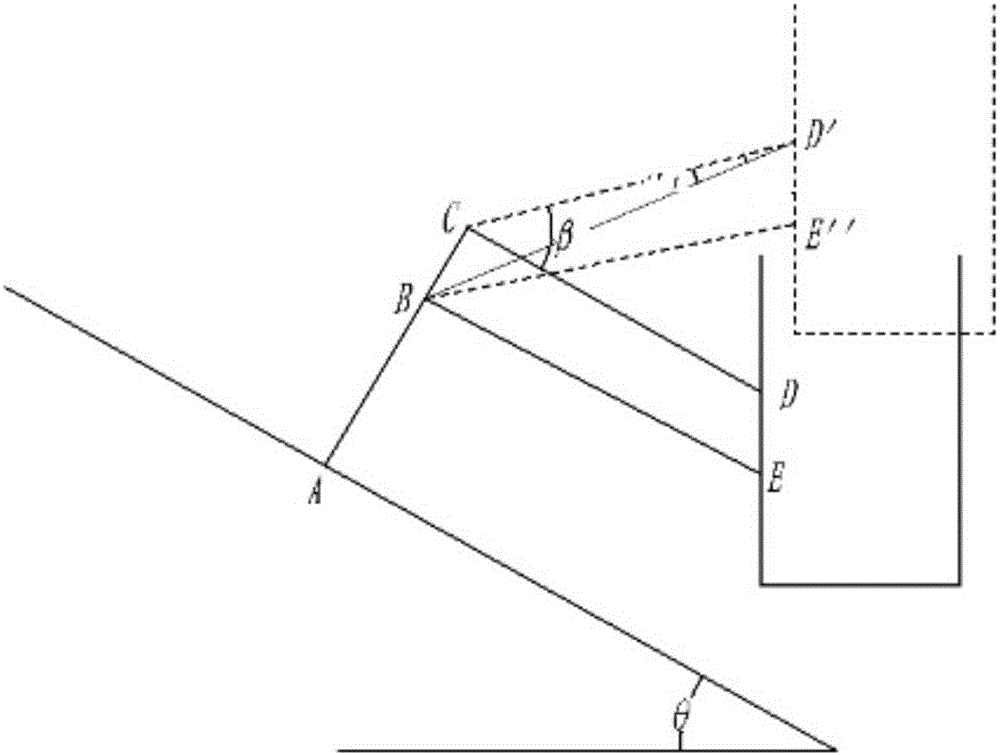

[0045] The angle sensor described in this embodiment is MPU6050; the displacement sensor module used is a BOSO cable displacement sensor module; the single-chip microcomputer system used is a STM32 single-chip microcomputer. The present invention connects and assembles the supporting mechanism, the leveling mechanism, the lifting mechanism, the working platform and the control system through a connecting ring, and the working platform 5 is in a horizontal position in the initial working state. When the working platform is picking apples on the flat ground, when the working platform 5 needs to be lifted according to the requirements of the operators, the control valve of the lifting cylinder 7 is adjusted to the upper position, and the lifting cylinder 7 moves, and the working platform 5 is lifted to the working position through the cross arm 3, and the lifting cylinder 7 is lifted to the working position. Adjust the control valve to the middle position and lock the lifting cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com