Bending device of bending tester

A bending test and bending device technology, used in measuring devices, instruments, and testing the strength of materials by applying a stable bending force, can solve the problems that affect the measurement effect and the bending device is easy to rotate, and improve the test accuracy. , easy to replace, reduce the effect of variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

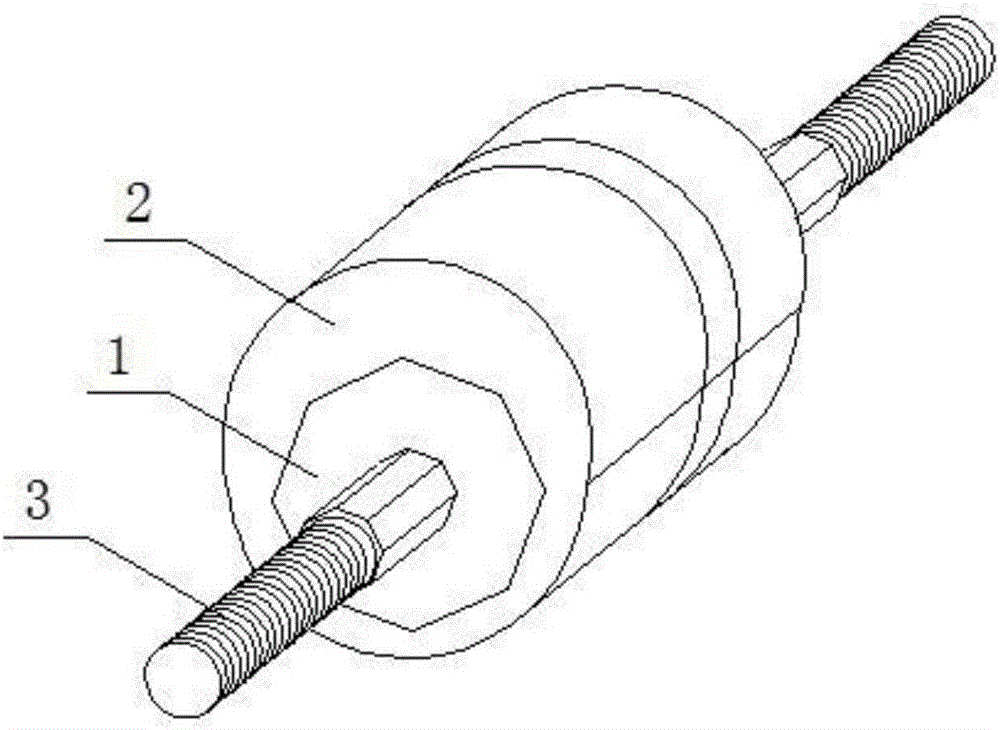

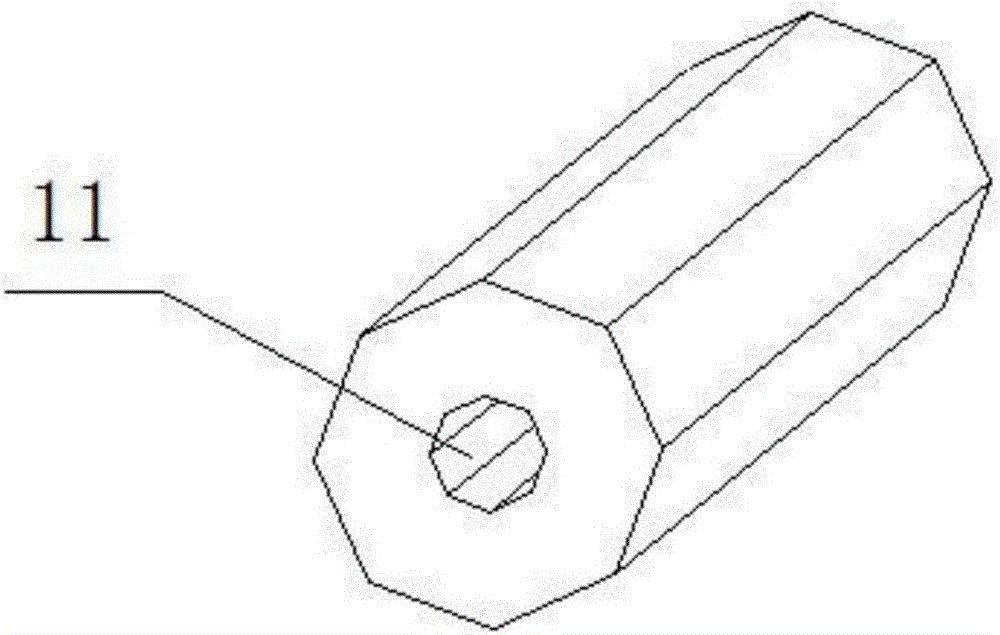

[0026] Such as Figure 1-Figure 3 As shown, a bending device of a bending tester is installed in the installation groove on the wire bending tester, and the two sides of the installation groove are provided with regular polygonal through holes, including a through hole column 1, and the through hole A fixed through hole 11 is arranged at the central axis of the hole post 1, and the axis of the fixed through hole 11 coincides with the through hole post 1. The fixed through hole 11 is provided with a regular polygonal fixed rod 3, and the two fixed rods 3 The end extends to the polygonal through holes on both sides of the installation groove; the through hole column 1 is covered with a wire bending sleeve 2, and the outer surface of the wire bending sleeve 2 is provided with a wire groove 22, and the through hole column 1. The length of the wire bending sleeve 2 is equal to the length of the installation groove.

[0027] The installation sequence of the bending device of a bend...

Embodiment 2

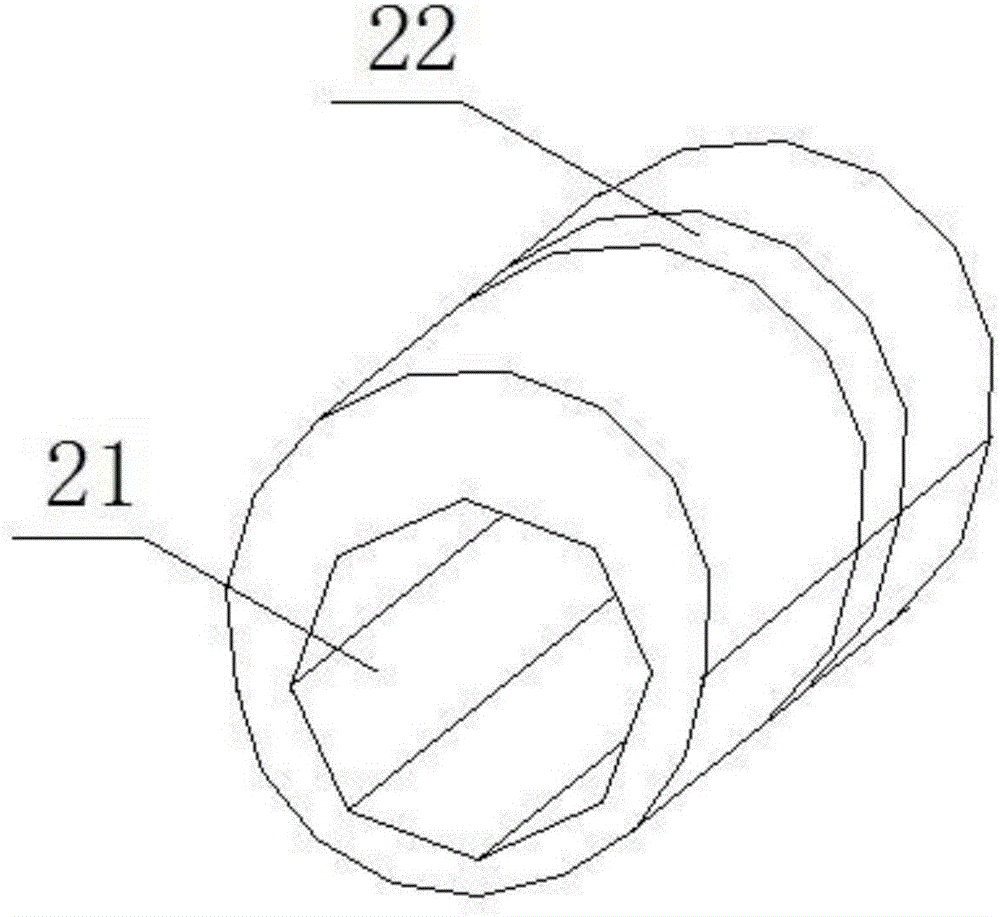

[0030] Further optimized on the basis of the bending device of a bending tester described in Example 1, the central axis of the wire bending sleeve 2 is provided with a connecting through hole 21, and the connecting through hole 21 is connected with the bending of the wire rod. The axis of the sleeve 2 coincides, and the through-hole column 1 is set in the connecting through-hole 21, and the shape and size of the connecting through-hole 21 and the through-hole column 1 are consistent. The setting of this embodiment makes the wire bending sleeve and the through-hole There are no gaps between the columns and no mutual movement occurs.

Embodiment 3

[0032] On the basis of the bending device of a kind of bending tester described in embodiment 1, it is further optimized. The cross-sections of the connecting through hole 21 and the fixing through hole 11 are all set as regular polygons. The setting of this embodiment can ensure that the through hole There is no relative sliding between the column, the wire bending sleeve and the fixed rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com