Making method of expandable breakage-proof yellow mud stemming for coal mines

A production method and blasting technology, applied in blasting and other directions, can solve problems such as ineffective prevention, fragility of yellow mud blasting columns, and reduction of eye opening resistance of explosives in blast holes, so as to improve eye opening resistance and enhance Blast effects, effects that improve integrity and overall utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

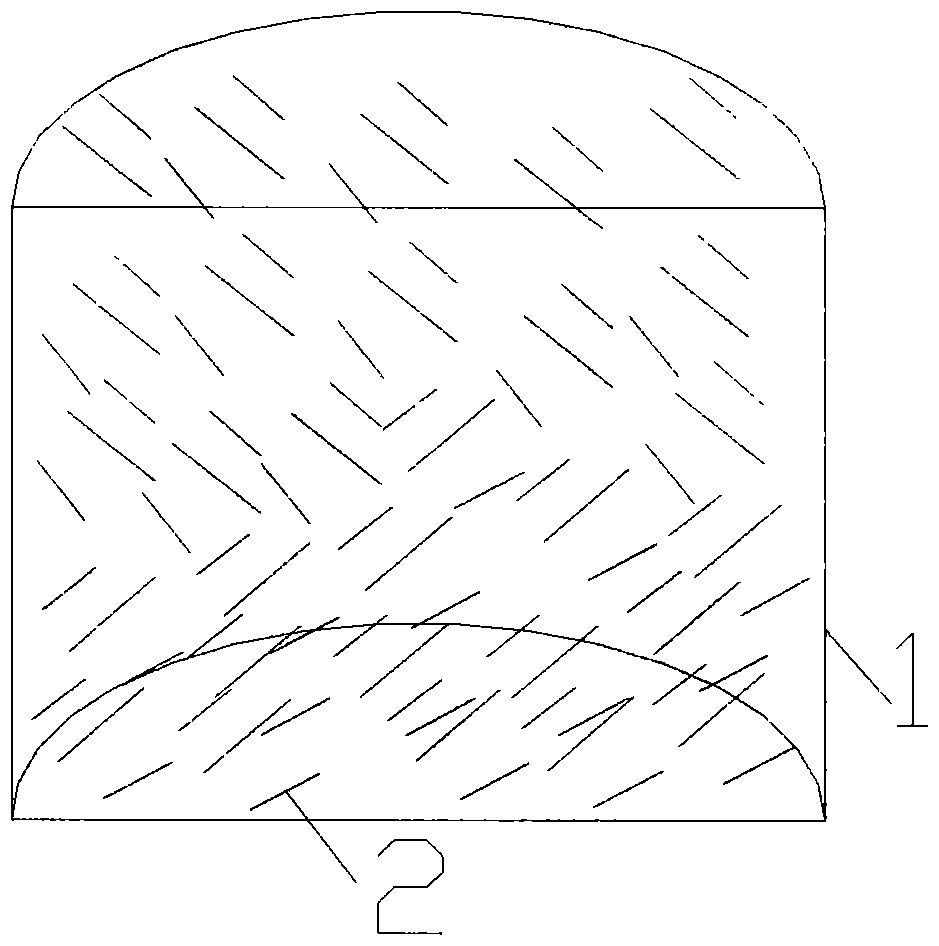

[0011] The described invention relates to a method for making expansion and anti-shattering yellow mud gun mud for coal mines, see attached figure 1 The above-mentioned gun mud is composed of asbestos fiber and yellow mud with expandable graphite flakes, and the amount of expandable graphite flakes added at the same time is not more than 30% of the total weight of the yellow mud gun mud; the asbestos fibers are cut into lengths Fibers larger than 30mm are stirred together with yellow mud and expandable graphite flakes. The length of the yellow mud column carved by the mold is not more than 30cm, and the diameter of the column is not more than 3cm. It is used after drying.

Embodiment 2

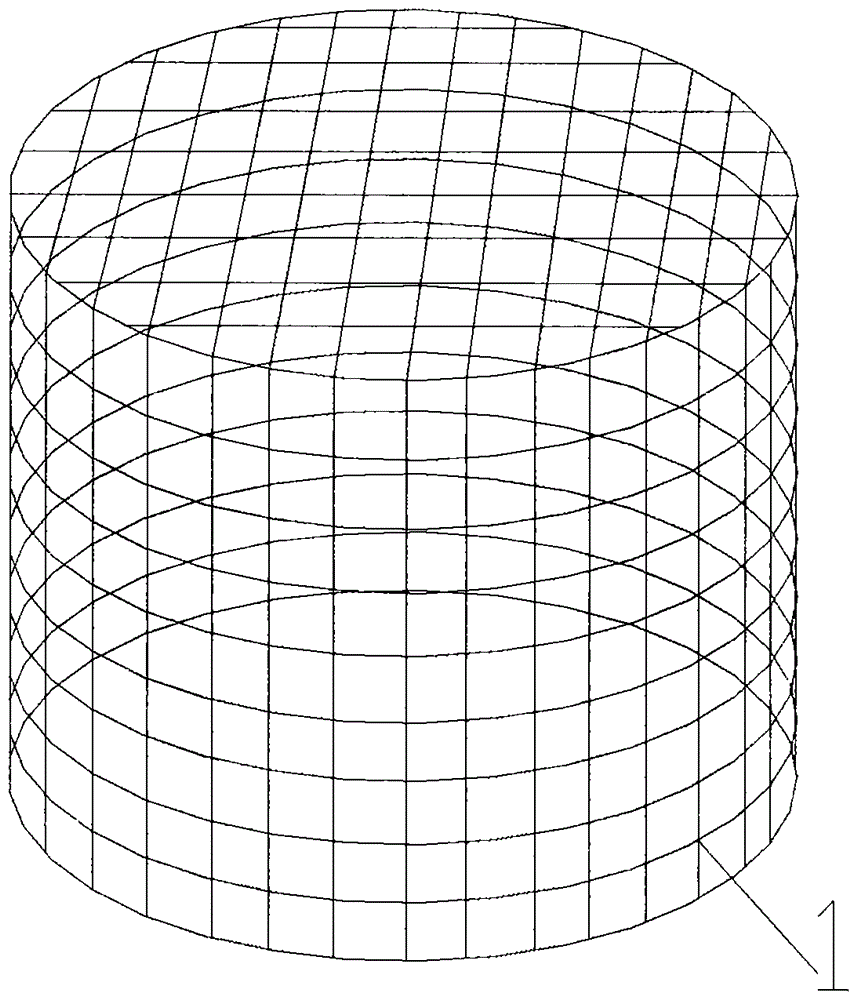

[0013] The described invention relates to a method for making expansion and anti-shattering yellow mud gun mud for coal mines, see attached figure 2 The above-mentioned gun mud is composed of asbestos fiber and yellow mud with expandable graphite flakes, and the amount of expandable graphite flakes added at the same time is not more than 30% of the total weight of the yellow mud gun mud; The asbestos net larger than 0.1mm and thickness not exceeding 1mm wraps the periphery of the engraved cylindrical yellow mud column. The length of each wrapped yellow mud column does not exceed 30cm, and the diameter of the column is not greater than 3cm. The bottom and top of the body are exposed and dried for use.

Embodiment 3

[0015] The described invention relates to a method for making expanded and anti-shattering yellow mud gun mud for coal mines, see accompanying drawing 3, the above-mentioned gun mud is composed of asbestos fibers and yellow mud with expandable graphite flakes, and the expandable graphite that joins in at the same time The amount of flakes is not more than 30% of the total weight of the yellow mud gun mud; the asbestos fiber is made into an asbestos net with a hole diameter of no more than 0.1mm and a thickness of no more than 1mm, and the yellow mud and expandable graphite flakes are rolled into the asbestos net. The mixture of mud and expandable graphite flakes is formed by wrapping layers of asbestos nets. The thickness of each layer of yellow mud and expandable graphite flakes is not more than 5mm, and the amount of expandable graphite flakes added is not more than yellow mud. The total weight is 30%, and the length of each yellow mud column is not more than 30cm, and the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com