Automatic cloth delivering and collecting device

A technology of automatic material reclaiming and cloth, applied in the textile field, can solve the problem of inability to adjust the induction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

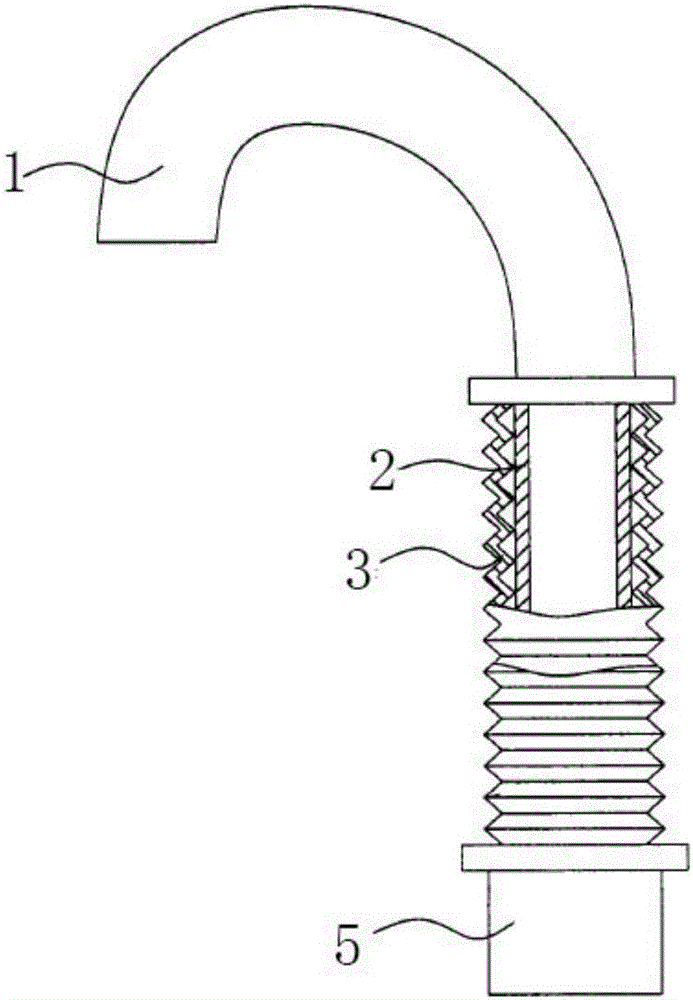

[0038] The device of the present invention includes an induction device body 1, a main induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the sensing device body 1 is detachably arranged on the main sensing device base 5, and the sub sensing device bases are installed in different positions, which is convenient for users to use. The base 5 of the total sensing device is connected to the cloth conveying roller. The base 5 of the total sensing device includes an optical receiving component, an infrared emitting component 22, a distance measuring component 13 and an infrared optical processing component 12. The bases of the sub-sensing devices are respectively provided with laser emitting components 6.

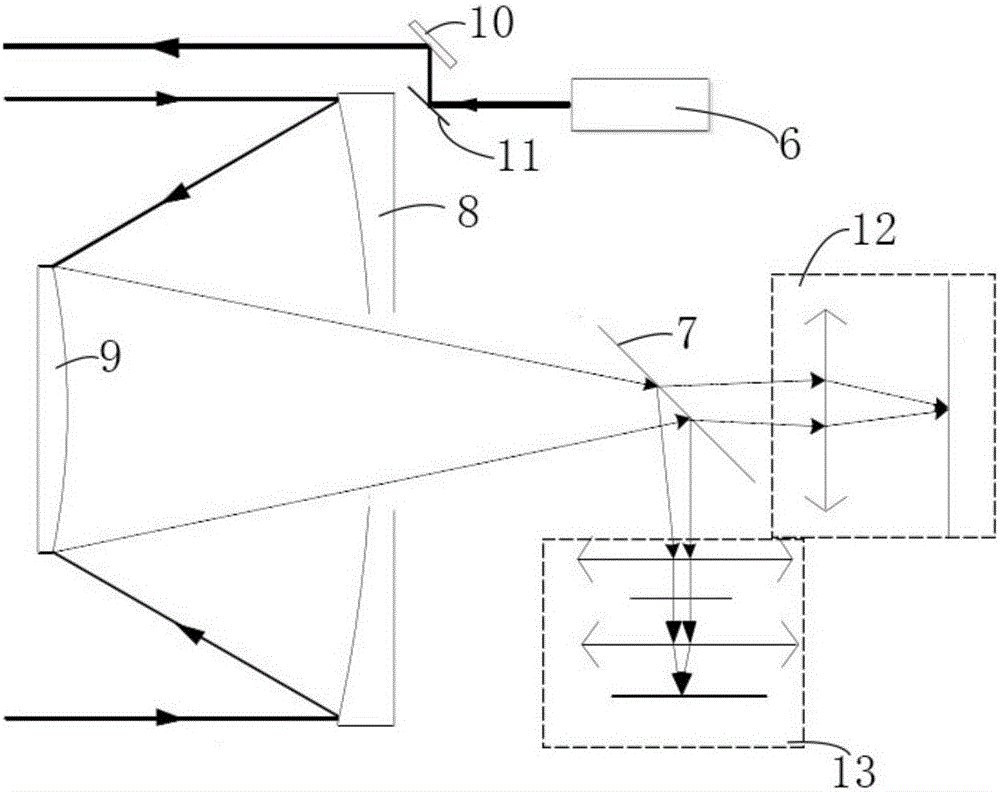

[0039] Such as figure 2 As shown, the optical receiving component can simultaneously receive laser and infrared rays, or receive laser or infrared rays separately. The optical receiving assembly includes a dichroic plate 7,...

Embodiment 2

[0075] The device of the present invention includes an induction device body 1, a main induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the sensing device body 1 is detachably arranged on the main sensing device base 5, and the sub sensing device bases are installed in different positions, which is convenient for users to use. The base 5 of the total sensing device is connected to the cloth conveying roller. The base 5 of the total sensing device includes an optical receiving component, an infrared emitting component 22, a distance measuring component 13 and an infrared optical processing component 12. The bases of the sub-sensing devices are respectively provided with laser emitting components 6.

[0076] Such as figure 2 As shown, the optical receiving component can simultaneously receive laser and infrared rays, or separately receive laser or infrared rays. The optical receiving assembly includes a dichroic plate 7,...

Embodiment 3

[0112] The device of the present invention includes an induction device body 1, a main induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the sensing device body 1 is detachably arranged on the main sensing device base 5, and the sub sensing device bases are installed in different positions, which is convenient for users to use. The base 5 of the total sensing device is connected to the cloth conveying roller. The base 5 of the total sensing device includes an optical receiving component, an infrared emitting component 22, a distance measuring component 13 and an infrared optical processing component 12. The bases of the sub-sensing devices are respectively provided with laser emitting components 6.

[0113] Such as figure 2 As shown, the optical receiving component can simultaneously receive laser and infrared rays, or separately receive laser or infrared rays. The optical receiving assembly includes a dichroic plate 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com