Long platform digital printing machine

A digital printing machine and platform technology, applied in printing, typewriters, printing devices, etc., can solve the problems that the length of the screw rod cannot be achieved, the precision is difficult to meet the production requirements, and digital printing cannot be realized, so as to achieve low equipment cost and easy debugging. Flexible and Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

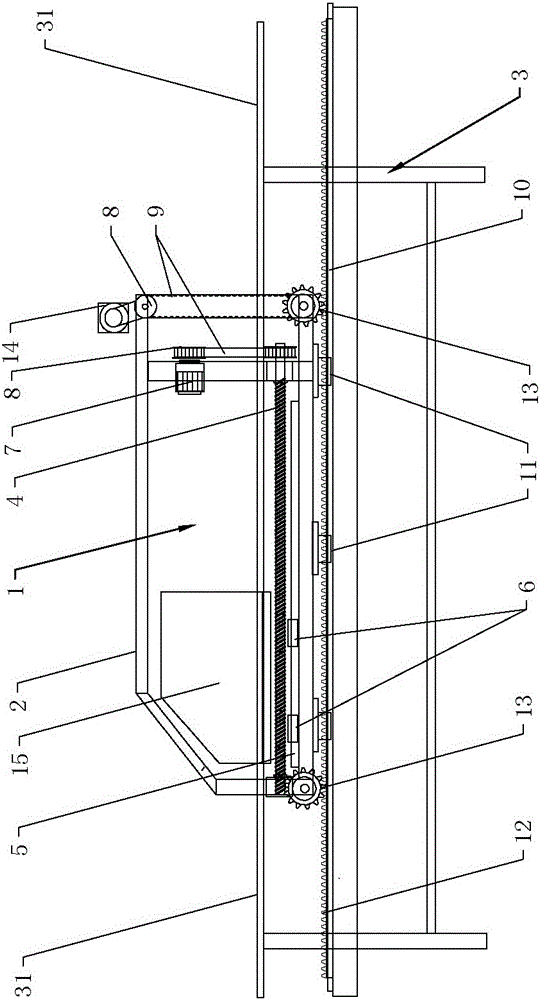

[0046] One of the embodiments of a long platform digital printing machine of the present invention, such as figure 1 It shows that it includes a stand 3 and a digital printer 15, wherein: a transmission trolley 1 and a trolley walking system are provided, and the transmission trolley 1 is provided with a transmission frame 2 and a first horizontal driving device, and the first horizontal driving device drives the digital printer 15 in the The drive frame 2 moves horizontally to and fro on the platform surface 31 parallel to the platform 3, and the trolley walking system is provided with a second horizontal driving device, which drives the transmission trolley 1 to reciprocate horizontally on the platform surface 31 parallel to the platform 3 move.

[0047] Thus, by setting the movable transmission trolley 1 and cooperating with the first horizontal driving device in the transmission trolley 1, the digital printer 15 will automatically return to the printing starting point on t...

Embodiment 2

[0061] One of the embodiments of a long platform digital printing machine of the present invention, such as figure 1 As shown, the main technical solution of this embodiment 2 is basically the same as that of embodiment 1, and the features not explained in this embodiment 2 are explained in embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that a controller is provided, and the controller is electrically connected to the first horizontal driving device, the second horizontal driving device and the digital printer respectively.

[0062] As mentioned above, the stand 3 and the transmission trolley 1 are respectively provided with mutually matching sensors, and the sensors are electrically connected to the controller.

[0063] The digital printer is driven by the transmission trolley 1 to print at each position on the platform surface 31 and is sensed to the end point by the sensor, and the transmission trolley 1 automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com