Machine tool table exchange system for flexible line of gantry machining center

A machining center and exchange system technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as unstable and discontinuous transmission, achieve rapid exchange, and improve transmission accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

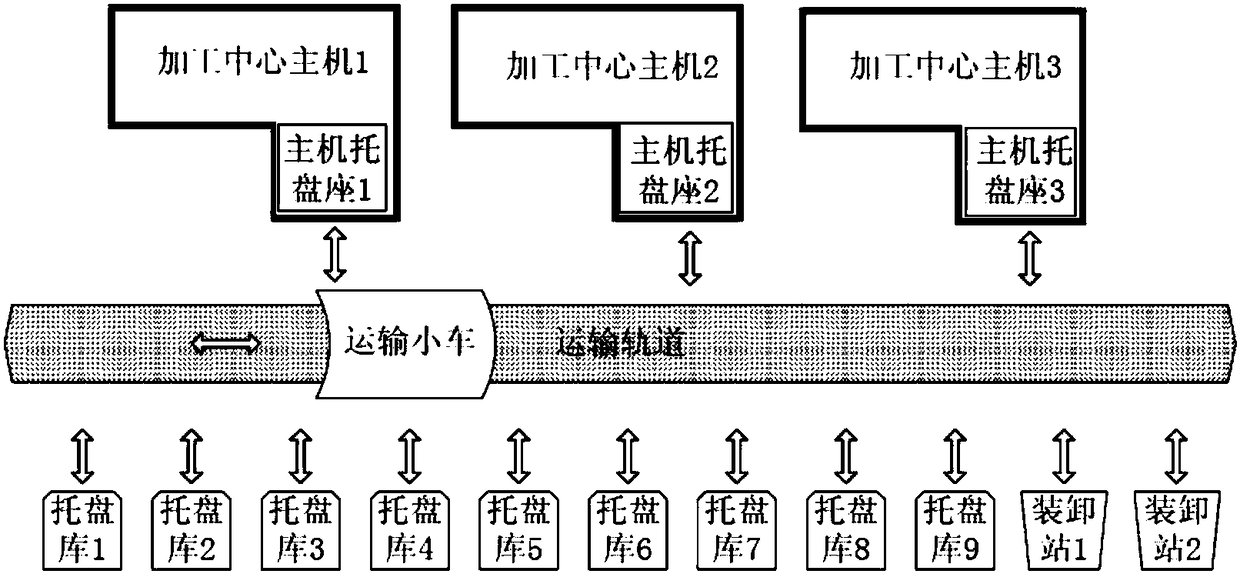

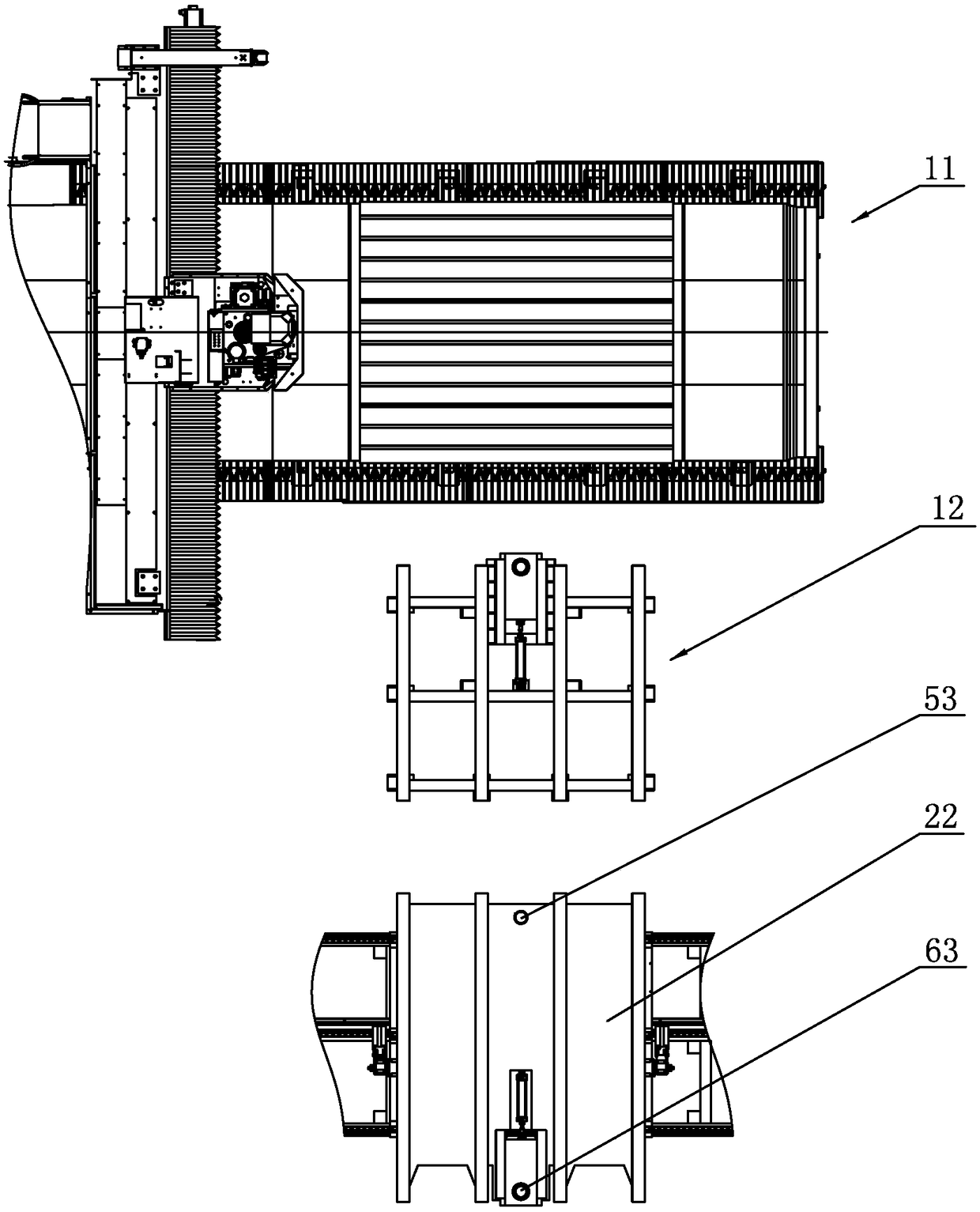

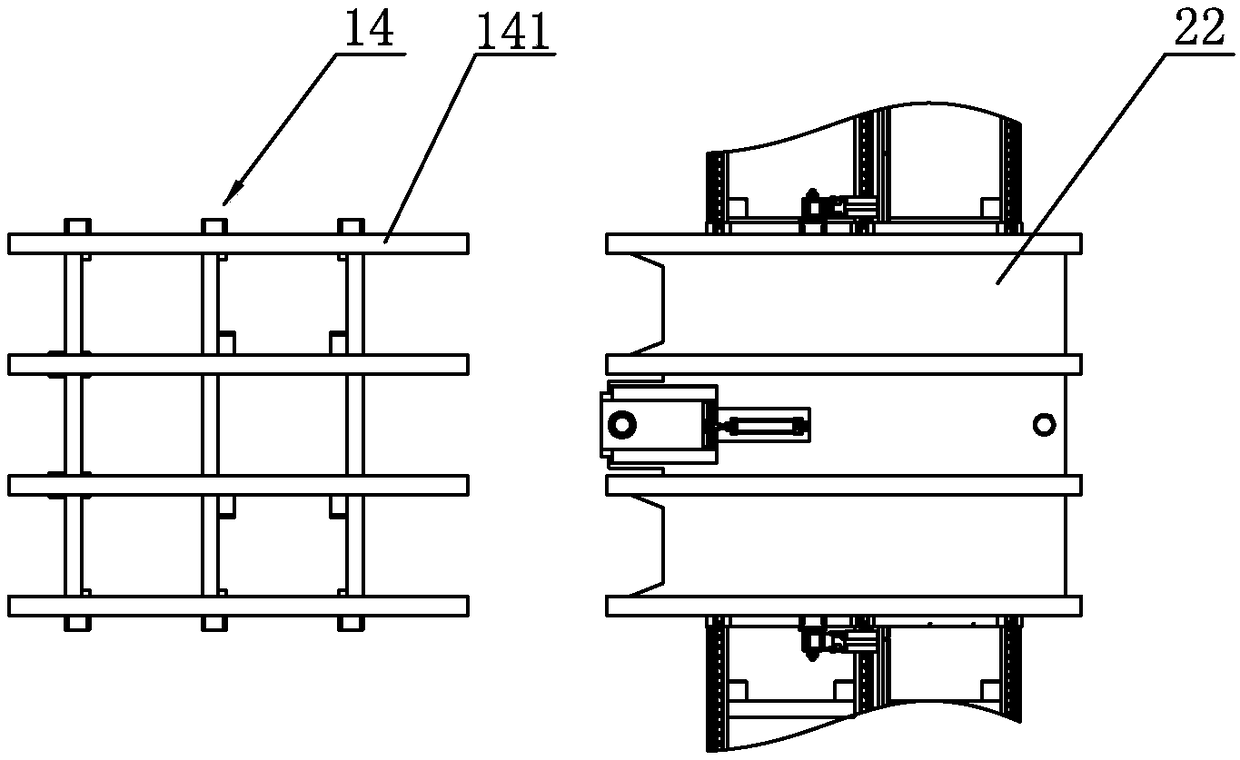

[0038] The machine tool table exchange system of the flexible line of the gantry machining center of the embodiment, as shown in the figure, includes multiple machining center hosts 11, multiple host tray seats 12, multiple pallet warehouses 13, multiple loading and unloading stations 14, and transport trolleys 2 and trolley track 15, figure 2 Shown in a machining center host 11, a host tray seat 12 and transport trolley 2, image 3 A loading and unloading station 14 and transport trolley 2 are shown in the figure; each main frame tray seat 12 is installed on the first support 121, each pallet warehouse 13 is installed on the second support 131, and each loading and unloading station 14 is installed on the third support (not shown in the figure), the transport trolley 2 is installed on the fourth bracket 21, and each machining center host 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com