Apparatus for cleaning reflective mask and method for cleaning reflective mask

一种清洗装置、反射型的技术,应用在清洁方法和用具、化学仪器和方法、图纹面的照相制版工艺等方向,能够解决反射型掩膜光学特性劣化、反射率降低等问题,达到抑制光学特性的劣化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments are illustrated below with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same component in each drawing, and detailed description is abbreviate|omitted suitably.

[0026] The object W to be cleaned may be an exposed layer including a material that is easily oxidized.

[0027] The object W to be cleaned may be, for example, a reflective mask having a coating layer containing ruthenium, a substrate having a coating layer containing ruthenium (a substrate in the process of manufacturing a reflective mask), or the like.

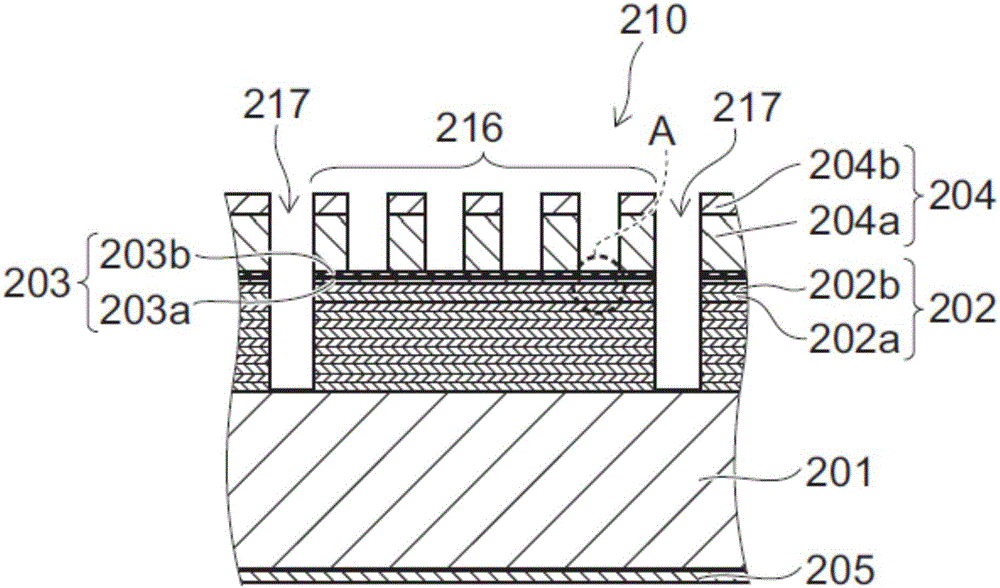

[0028] figure 1 It is a schematic cross-sectional view illustrating a reflective mask 210 as an object W to be cleaned.

[0029] Such as figure 1 As shown, a reflection layer 202 , a cover layer 203 , and an absorption layer 204 are stacked in this order on one main surface of a substrate 201 .

[0030] In addition, a conductive layer 205 is formed on the other main surface of the substrate 201 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com