Matching method of real-time three-dimensional visual virtual monitoring for intelligent manufacturing

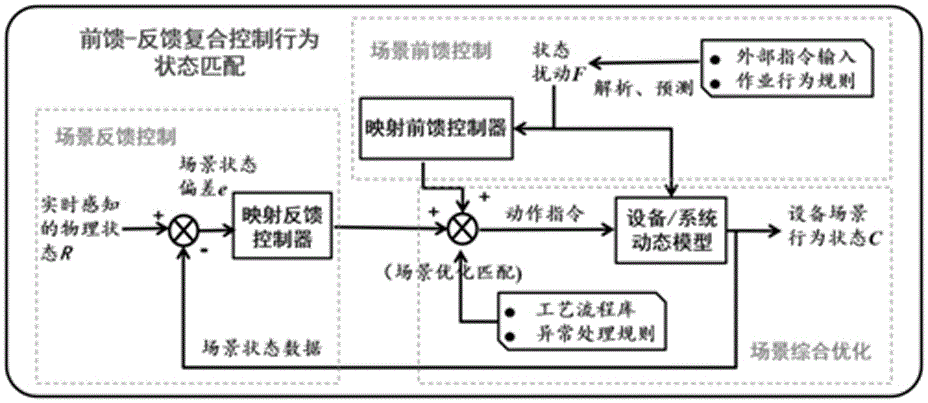

A real-time three-dimensional, intelligent manufacturing technology, applied in the field of control, can solve problems such as large delay, achieve the effect of optimizing virtual scenes and improving the real-time performance of actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

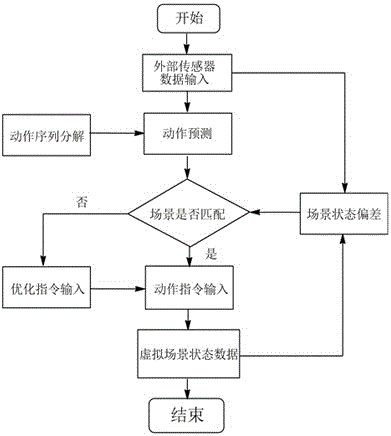

[0025] Such as figure 1 as well as figure 2 As shown, taking the AGV transportation task in the workshop as an example, the specific steps are as follows:

[0026] 1) The location information of the AGV is read through RFID technology. First, the AGV transportation path is divided into multiple small sections, and each small section is based on the RFID radio frequency card to ensure that there is a radio frequency card on each section; the current AGV transportation task is obtained through the host computer server The specific walking route of the AGV, so that the decomposed small path segments are sorted according to the task operation requirements; when the AGV reads the radio frequency card during operation, it predicts the next path that the AGV will take according to the current position information, and uses the radio frequency card number of the next path as Feedforward output;

[0027] 2) When the AGV reads the radio frequency card during operation, the AGV model ...

Embodiment 2

[0030] Taking the manipulator task in the workshop as an example, the specific steps are as follows:

[0031] 1) The manipulator is equipped with an angle sensor and a position sensor, which can accurately sense the current position and angle of the manipulator. Firstly, the action sequence of the manipulator is established according to the process requirements. During the operation of the manipulator, when the previous process action is about to end, it predicts the next action against the action sequence and outputs it as a feed-forward;

[0032] 2) When the last process action is about to end, the current position deviation is obtained according to the information of the real-time position sensor and angle sensor and the current coordinate position of the manipulator in the virtual scene, and the deviation is output as feedback;

[0033] 3) Combining the output of feedforward and feedback, the next action command of the manipulator model in the virtual scene is obtained. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com