Online analysis method of hardness distribution of coke layers in coke tower during hydraulic decoking

A technology of hydraulic decoking and hardness distribution, applied in the direction of testing material hardness, etc., can solve the problems of increasing decoking accidents such as sticking, major production and safety, low decoking efficiency, etc., to shorten the decoking operation time and reduce installation. Requirements, the effect of saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

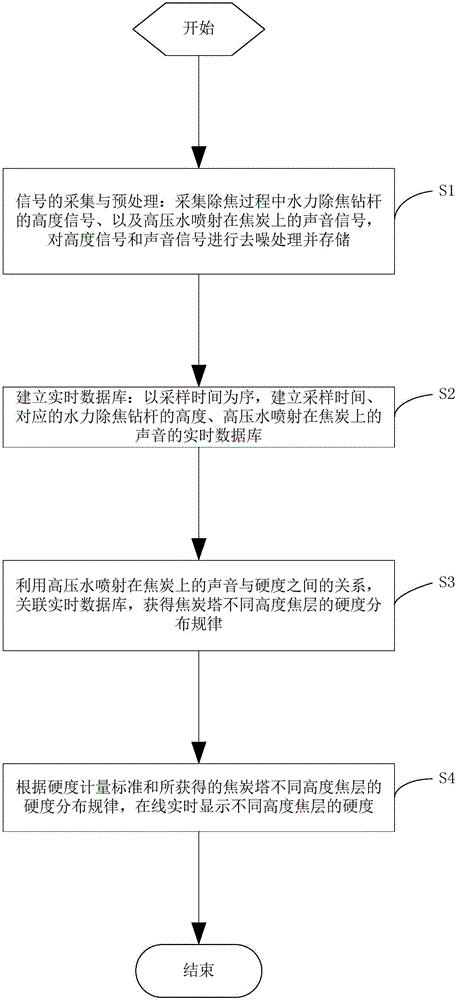

[0022] The invention provides an online analysis method for the hardness distribution of the coke layer in the coke tower in the hydraulic decoking process, such as figure 1 shown, including the following steps:

[0023] S1. Signal collection and preprocessing: collect the height signal of the hydraulic decoking drill pipe during the decoking process, and the sound signal of high-pressure water sprayed on the coke, and denoise the height signal and sound signal and store them; Coke refers to the coke on the inner wall of the coke tower.

[0024] S2. Establish a real-time database: in order of sampling time, establish a real-time database of sampling time, the height of the corresponding hydraulic decoking drill pipe, and the sound of high-pressure water spraying on the coke.

[0025] In this embodiment, a set of programs for managing real-time data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com