A traceable liquid sinusoidal pressure calibrating device

A technology for calibrating devices and pressures, applied in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems of unreliable traceability of dynamic pressure values, limited range, etc., to eliminate system errors, improve measurement accuracy, and increase frequency bandwidth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

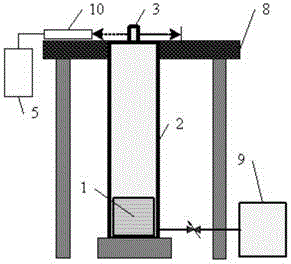

[0018] Such as figure 1 , figure 2 As shown, a traceable liquid sinusoidal pressure calibration device includes a liquid sinusoidal pressure generator, a liquid dynamic pressure laser interferometry system, a vibration isolation platform, a static pressure loading system, and a data acquisition and analysis system.

[0019] The liquid sinusoidal pressure generator includes a piezoelectric transducer 1, a main resonant lumen 2, a sub-resonant lumen 3, and a flexible connector 4; the main resonant lumen 2 and the sub-resonant lumen 3 are connected through a flexible connector 4; The resonant tube cavity 2 is used to generate the resonance of the water medium at a series of equally spaced resonance points, and its length is designed according to the first-order resonance frequency and the quarter-wavelength formula; the sub-resonant tube cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cavity length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com