Automatic pipeline roundness value detection method

A technology for automatic detection and roundness value, which is applied to measuring devices, instruments, and optical devices, etc. It can solve the problems of accidental errors in measurement accuracy and large random errors, and achieve the effect of accurate judgment, reducing interference and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

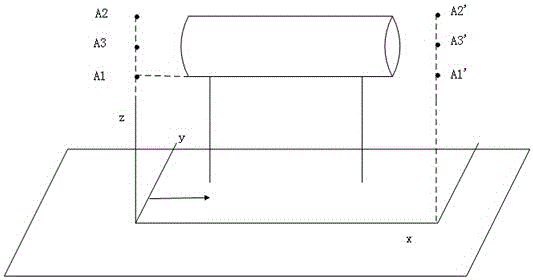

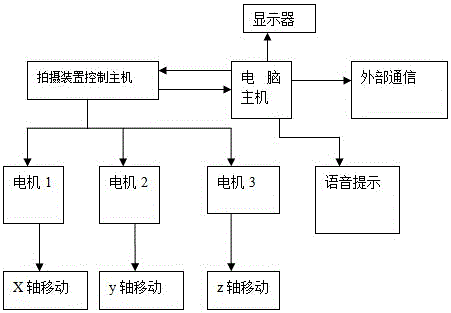

[0039] like figure 1 , figure 2 and image 3 As shown, the automatic detection method of pipe roundness value, the specific method is:

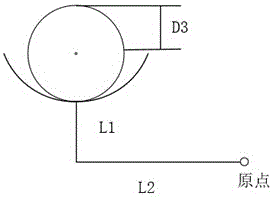

[0040] Adjust the horizontal distance between the image acquisition device (such as a camera or camera) and the end face of the pipe, so that the outer edge of the collected pipe end face in the diameter direction is the minimum distance from the image frame collected, which is less than or equal to the side length of the image frame parallel to the distance direction 5%; after adjusting the horizontal distance, image acquisition is performed on the end face of the pipeline, and the collected image is sent to the image processing system; the image processing system performs image processing on the collected end face image to extract the edge of the end face, and obtains the roundness value of each end face .

[0041] The image acquisition device collects the image of the end face of the pipeline. Before the image acquisition, the horizont...

specific Embodiment 2

[0043] On the basis of the specific embodiment 1, the method further includes using a laser ranging module to detect the horizontal distance between the image acquisition device and the end face of the pipeline. By detecting the horizontal distance between the image acquisition device and the end face of the pipeline, the specific position of the image acquisition focus of the image acquisition device is determined.

specific Embodiment 3

[0044] On the basis of the specific embodiment 1 or 2, the method further includes, using the image acquisition device to align with the center of the end surface of the pipeline to acquire images of the two end surfaces.

[0045] In addition to adjusting the horizontal distance between the image acquisition device and the end face of the pipeline, it also includes adjusting the position of the image acquisition device so that the image acquisition focus of the image acquisition device is aligned with the center of the end face of the pipeline for image acquisition, and then the end face of the pipeline is adjusted. Image Acquisition. Use an image acquisition device (such as a camera or camera) to align the center of the circle for image acquisition. Before image acquisition, adjust the position of the image acquisition device so that the focus of image acquisition is aligned with the center of the pipe end face, and the line connecting the focus of image acquisition and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com