Grease gun capable of preventing flowing back of lubricating oil

A technology of grease gun and lubricating oil, applied in the direction of lubricating oil control valve, lubricating parts, manual supply of lubricant, etc., can solve the problems of affecting work efficiency, lubricating oil backflow, waste of resources, etc., to improve work efficiency and reasonable structure , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

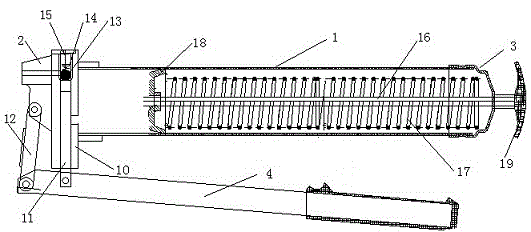

[0014] A grease gun capable of preventing lubricating oil from flowing back, comprising an oil barrel 1, a gun head 2 respectively placed on the head and bottom of the oil barrel, a rear cover 3, and a handle 4 placed on one side of the oil barrel, and a rubber handle is provided on the handle set.

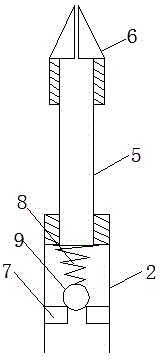

[0015] The end of the gun head is threadedly connected with an oil pipe 5, and one end of the oil pipe stretches into the inner chamber of the gun head and is threadedly connected with it, and the other end is threadedly connected with a tapered oil nozzle 6. The inner cavity of the gun head is provided with a perforated spacer 7, a spring 8, and a check ball 9. One end of the spring is against the oil pipe port placed in the inner cavity of the gun head, and the check ball is clamped on the other end of the spring and the perforated spacer. Between, the diameter of the non-return ball is larger than the hole diameter of the spacer with holes.

[0016] A pump body 10 and a mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com