Installation and lowering device for large penstock on high slope and penstock installation method

A pressure steel pipe and slope technology, which is applied in the directions of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., to achieve the effect of increasing safety, speeding up construction period and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

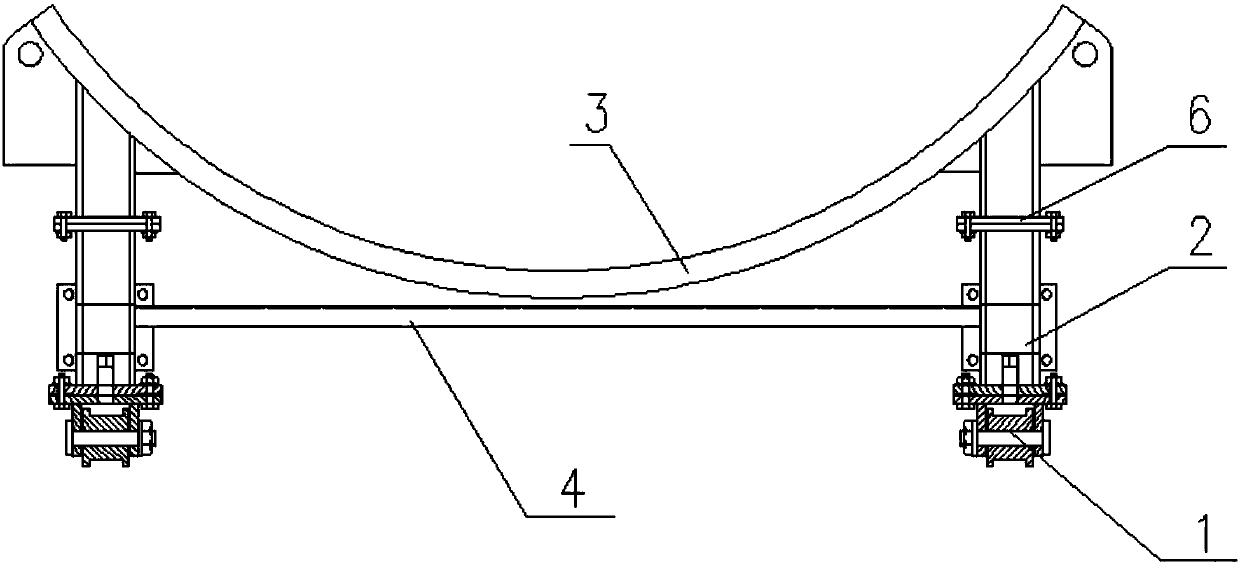

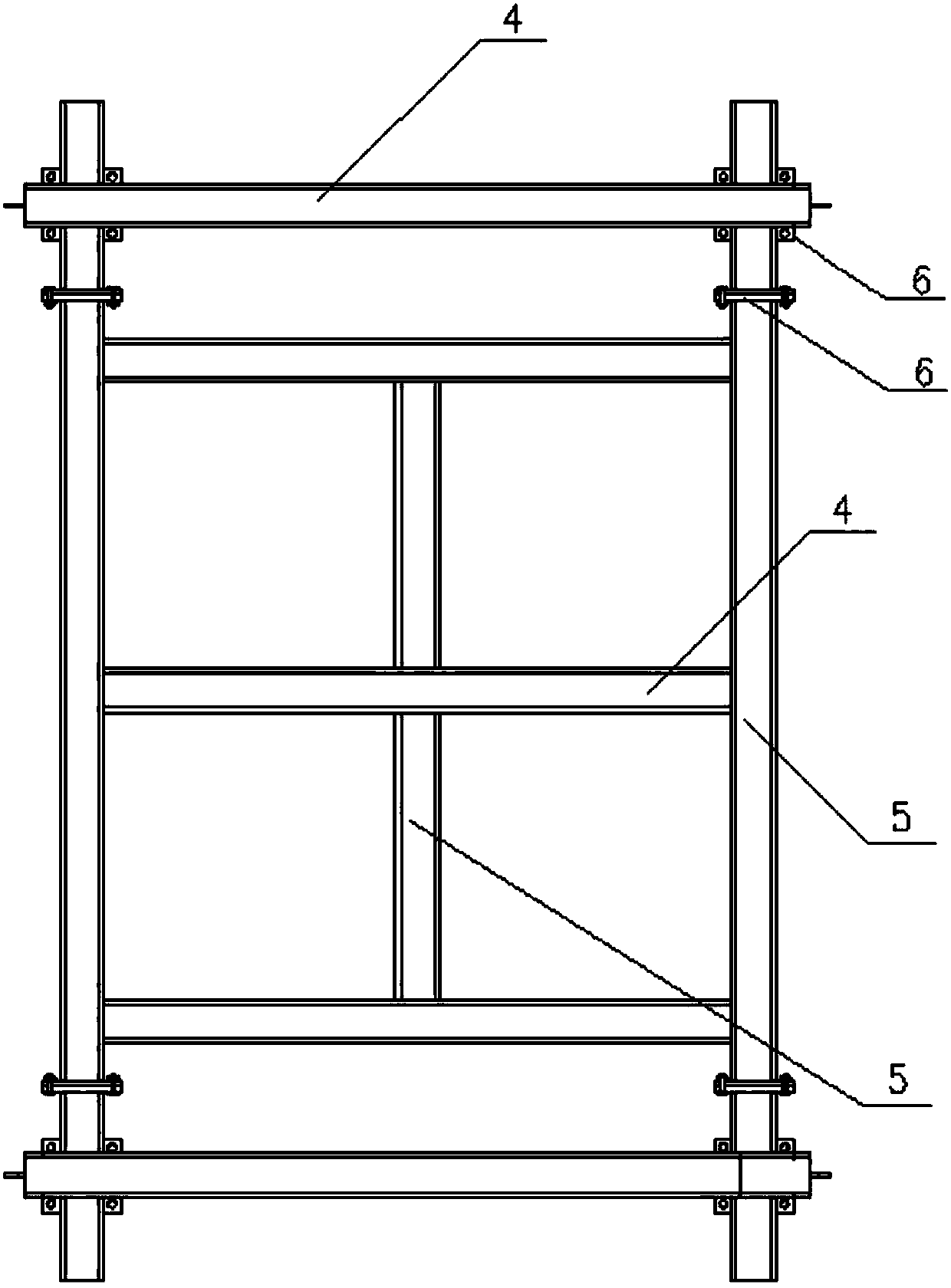

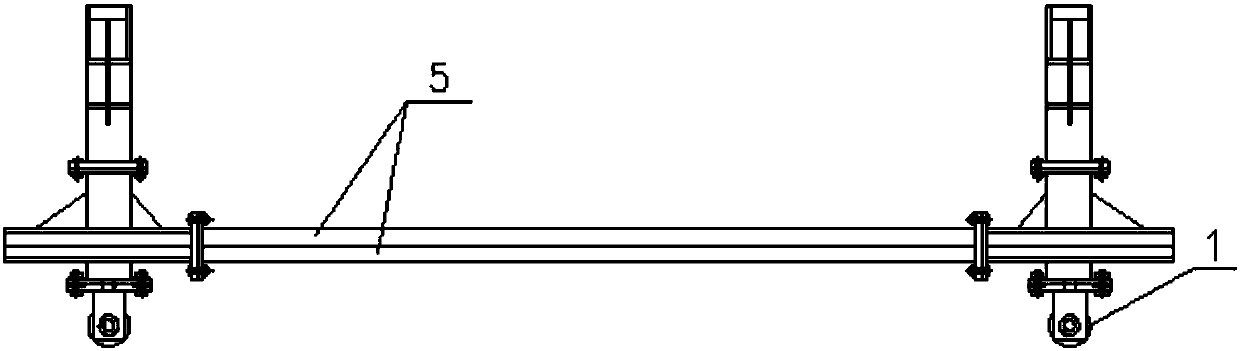

[0051] Such as Figure 1 to Figure 13 As shown, a descending passage is set on the side of the high slope, and the descending passage is composed of a horizontal section and a slope section, and the slope section includes a first steep slope section, a gentle slope section and a second slope section. The installation and release device for large-scale pressure steel pipes on high slopes includes trolleys 30 with rotating parts, rails and traction devices for traction trolleys 30; The support part, the support part includes a front support part, a middle support part and a rear support part, and the front support part and / or the rear support part are detachably connected with the steel pipe bracket 3; Set up the towing device.

[0052] Preferably, the concrete layer 16 is set under the track, if the original layer 18 (original foundation) is uneven, a filling layer 17 can be set between the original layer 18 and the concrete layer 16, and the filler of the filling layer 17 can...

Embodiment 2

[0080] Embodiment two: basically the same as embodiment one, the difference is:

[0081] Both the top plate 7 of the wheel set and the bottom plate 8 of the trolley bracket in Embodiment 1 adopt flanges, which can enhance the strength of the two components on the one hand, ensure the stable operation of the trolley 30, and ensure more precise connection of the two components on the other hand. .

[0082] Such as Figure 14 As shown, the penstock adopts two pipelines (line 1 and line 2) in the open pipe layout. According to the layout characteristics, in consideration of safety and construction progress, each line is equipped with a set of lowered traction devices. The advantages of this layout are Alternate lowering operations can be realized, which avoids cross operations in the construction of lowered parts, first of all, it is guaranteed in terms of safety, and secondly, it avoids the transfer of construction equipment caused by single-line operations, resulting in increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com