Water-saving spool and its fluid supply system

一种节水阀、阀芯的技术,应用在阀细节、阀装置、多通阀等方向,能够解决粗略控制出水温度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

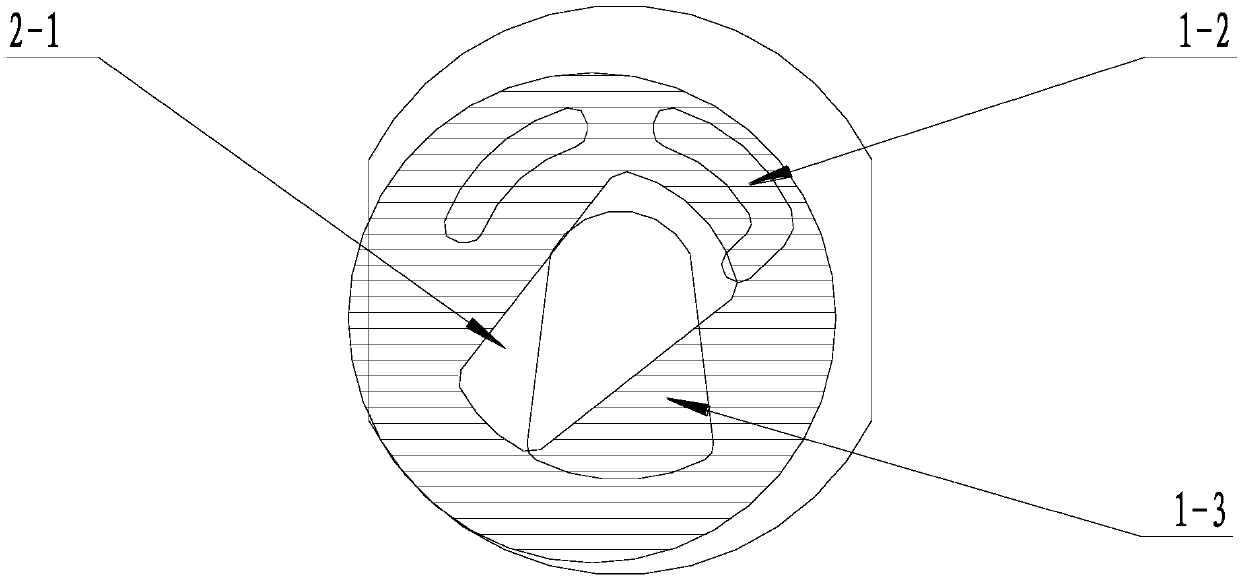

[0083] A valve device, comprising a valve device for controlling a fluid passing state when the fluid passes through, and an operating mechanism for realizing the aforementioned control by operating in its operating region, the valve device has a first fluid inlet port, a second fluid inlet port and a fluid At the outlet end, the operation area of the operating mechanism is divided into a mixing degree adjustment area for adjusting the mixing degree of the first fluid and the second fluid, and a flow adjustment area for adjusting the flow rate of the fluid outlet in the mixing degree adjustment area. The mixing degree adjustment area includes necessary The fluid outlet port exits only the first fluid region of the first fluid, and the fluid outlet port exits only the second fluid region of the second fluid, and there may be a fluid outlet port exiting the mixing region of the mixed fluid of the first fluid and the second fluid The flow rate of the operating mechanism at the m...

Embodiment 2

[0091] This embodiment is similar to Embodiment 1, except that in this embodiment, the critical state is set to the stop position in the heat-only mode, and the stop position in the cooling-only mode is the closed state of the spool.

[0092] The valve device of this embodiment, and the thermal fluid supply device (such as various water heaters) etc. which have a heating system for heating the fluid in it constitute a thermal fluid supply system, the thermal fluid outlet of the thermal fluid supply device and the first valve device A fluid inlet port (hot fluid inlet port, such as a hot water inlet hole) is connected, and is controlled by the operating mechanism of the valve device (including direct control or indirect control). The hot fluid supply device turns on or off its hot fluid supply, and the hot fluid supply device There is a minimum flow rate to close its heating system. When the flow rate of the first fluid inlet port (hot fluid inlet port, such as a hot water inlet...

Embodiment 3

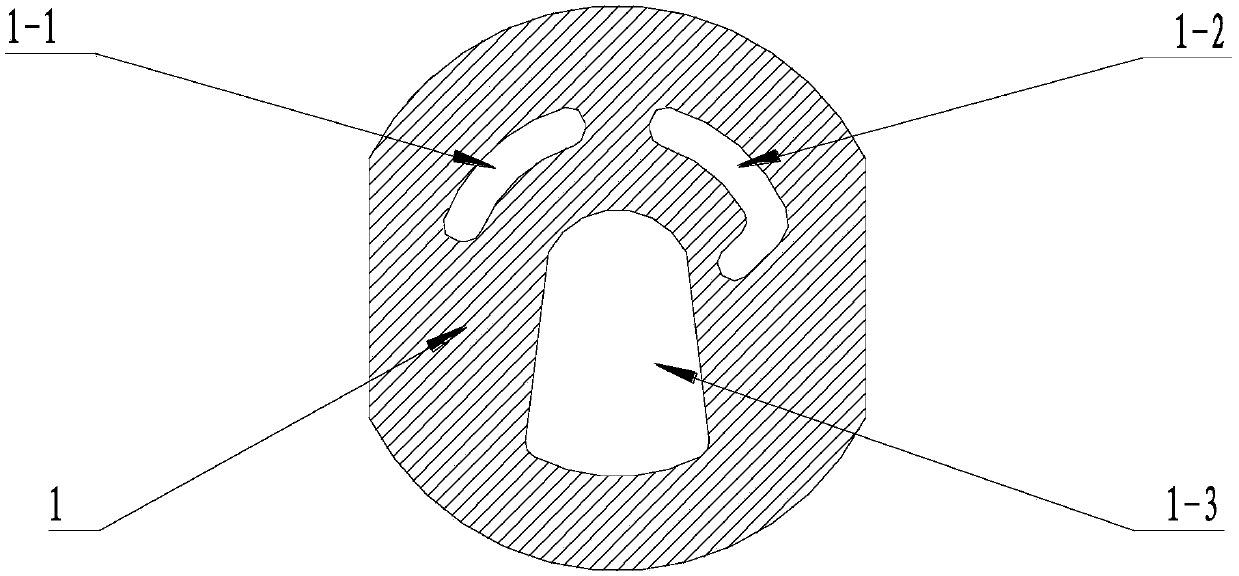

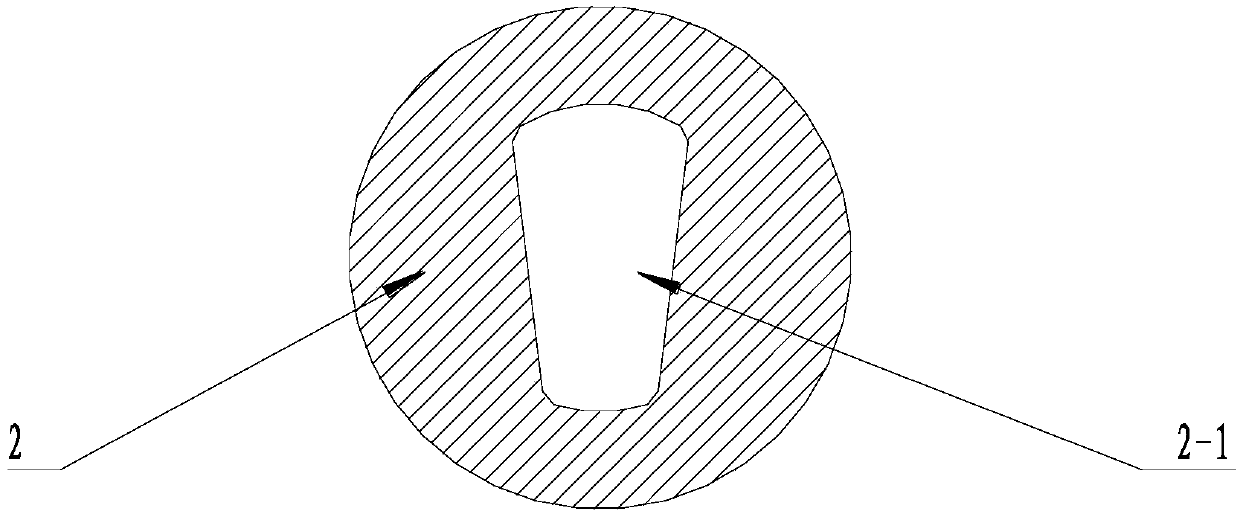

[0095] Such as Figure 1 to Figure 6 As shown, this embodiment is basically the same as Embodiment 1, more specifically, it is a ceramic single-handle double-connected water-saving valve core, the valve core mode has a single-heating mode and a single-cooling mode, and the control handle has an upper stop position , adjustment area and bottom stop position, the state of the spool has an open state and a closed state, when the control handle is placed at the bottom stop position of the single heat mode, the water-saving valve core is in the critical state of the single heat mode, and the control handle is placed in the only cooling mode The water-saving spool is in the closed state when it is in the stop position. From the bottom stop in the heat-only mode to the top stop in the heat-only mode is the large flow adjustment area of the water-saving spool in the heat-only mode. From the bottom stop in the heat-only mode to the cooling-only mode The stop position is the small flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com