Viscous damping wall integrated supporting system and construction method

A viscous damping wall and support system technology, applied in the direction of walls, pillars, building components, etc., can solve various problems, difficult adjustment, difficult concrete pouring of damping walls, etc., to ensure the construction quality and reduce the difficulty of support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

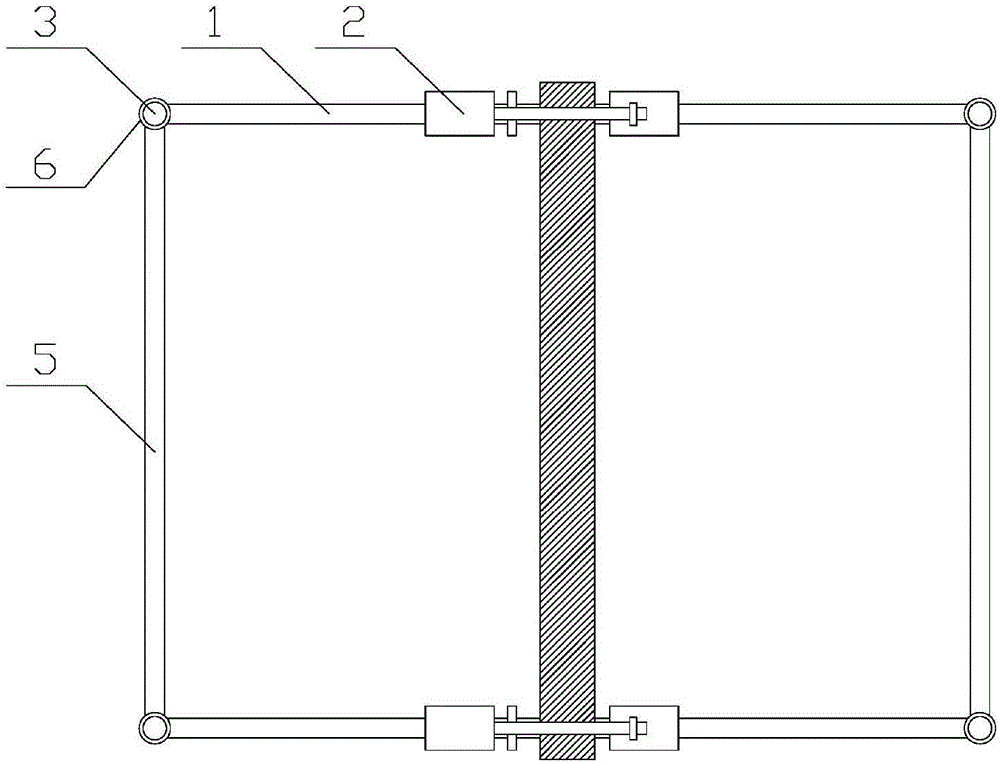

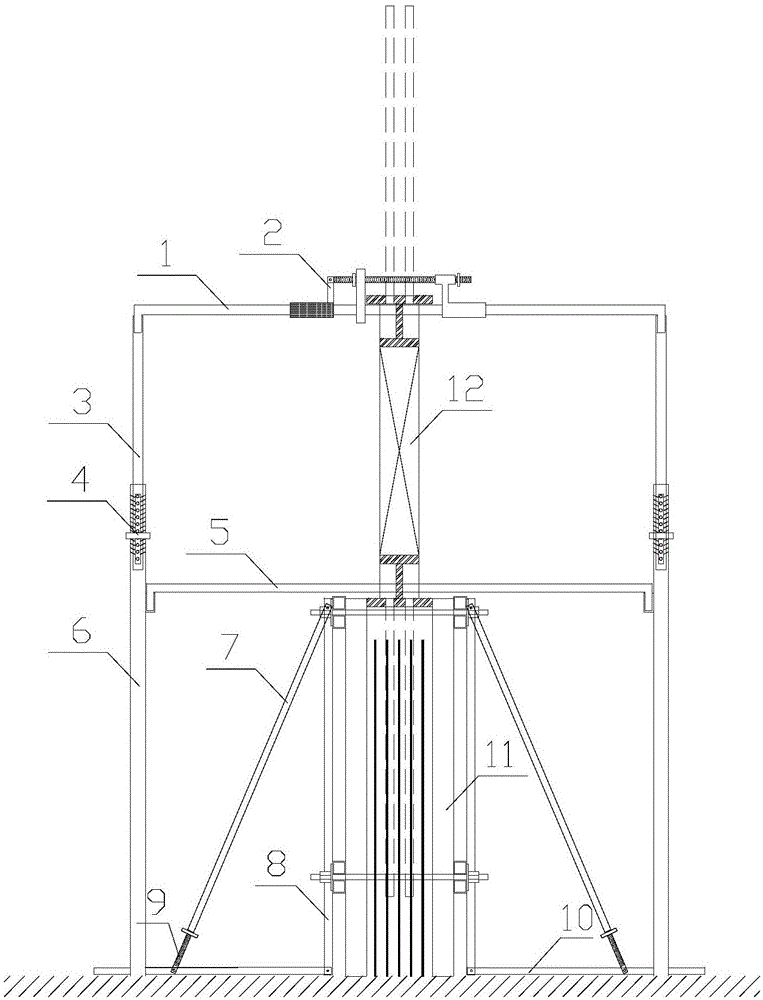

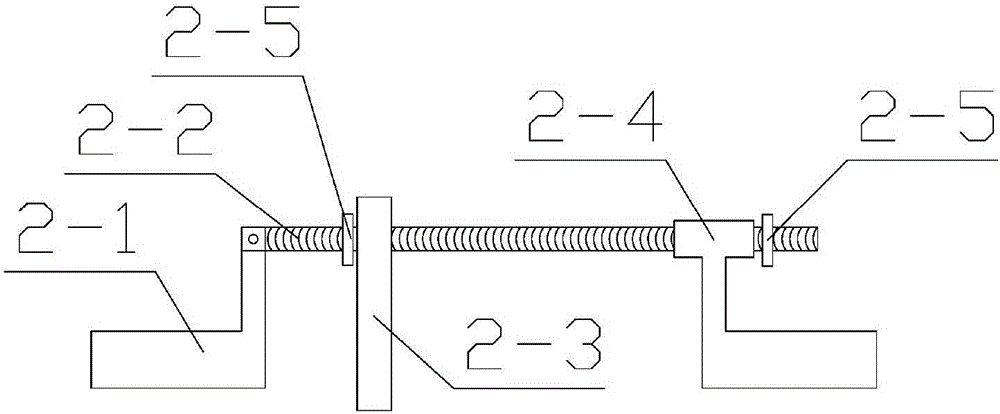

[0020] Such as figure 1 , figure 2 , image 3 As shown, the viscous damping wall integrated support system of the present invention includes four load-bearing vertical rods, two load-bearing horizontal rods 1, two adjustment devices 2, six horizontal tie rods 5, four diagonal braces 7, and four channel steel 8. Four bottom channel steels 10, characterized in that each load-bearing vertical rod is composed of an upper vertical rod 3, a lower vertical rod 6 and an adjusting nut 4, and the lower part of the upper vertical rod 3 is provided with equally spaced socket holes and supporting Latch, the lower end of the upper vertical rod 3 is placed in the lower vertical rod 6 and is fixed by a supporting latch. The upper part of the lower vertical rod 6 is provided with a thread opening and an adjusting nut 4, which can adjust the fixed position of the upper vertical rod 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com