Anti-mold paper packing box and producing process thereof

A packaging box, anti-mold technology, applied in packaging, wrapping paper, wrapping paper, etc., can solve the problems of the quality of the inner packaging, easy to be damp, moldy, etc., to extend the service life, good stability, good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

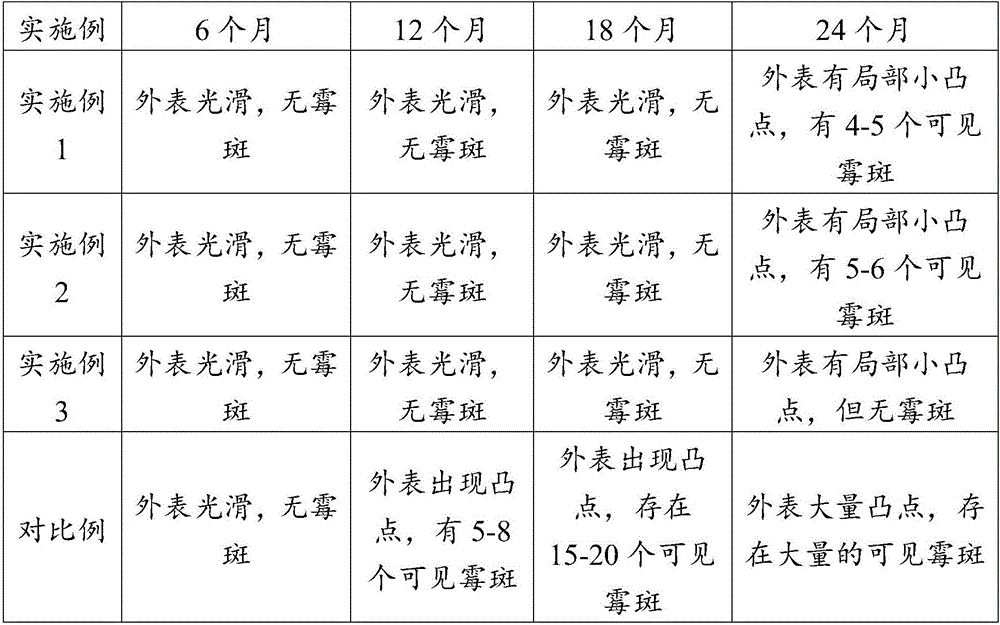

Embodiment 1

[0019] The anti-mildew paper packaging box includes the packaging box body, the outer surface of the packaging box body is provided with at least one layer of anti-mold coating layer, and the anti-mold coating layer is processed by the following raw materials in parts by weight: 50 parts of polyacrylic acid emulsion , 30 parts of PU resin copolymer emulsion, 4 parts of polyvinyl alcohol, 0.5 part of defoamer, 0.1 part of inorganic fungicide, 1 part of organic bentonite, 1 part of magnetic ordered mesoporous carbon;

[0020] The inorganic bactericide is a mixture of zinc chloride and cuprous chloride in a mass ratio of 1:2, and the preparation process of the anti-mildew paper packaging box is carried out as follows:

[0021] (1) Processing of semi-finished cardboard for packaging boxes, the moisture content of semi-finished cardboard is ≤2.5%;

[0022] (2) Pretreatment of the semi-finished cardboard of the packaging box: process the semi-finished product of the packaging box in...

Embodiment 2

[0027] The anti-mildew paper packaging box includes the packaging box body, the outer surface of the packaging box body is provided with at least one anti-mold coating layer, and the anti-mold coating layer is processed by the following raw materials in parts by weight: 60 parts of polyacrylic acid emulsion , 40 parts of PU resin copolymer emulsion, 6 parts of polyvinyl alcohol, 0.7 parts of defoamer, 0.3 parts of inorganic bactericide, 3 parts of organic bentonite, 3 parts of magnetic ordered mesoporous carbon;

[0028] The inorganic bactericide is a mixture of zinc chloride and cuprous chloride in a mass ratio of 2:3, and the preparation process of the anti-mildew paper packaging box is carried out as follows:

[0029] (1) Processing of semi-finished cardboard for packaging boxes, the moisture content of semi-finished cardboard is ≤2.5%;

[0030] (2) Pretreatment of the semi-finished cardboard of the packaging box: process the semi-finished product of the packaging box in a ...

Embodiment 3

[0035] The anti-mildew paper packaging box includes the packaging box body, the outer surface of the packaging box body is provided with at least one anti-mold coating layer, and the anti-mold coating layer is processed by the following raw materials in parts by weight: 55 parts of polyacrylic acid emulsion , 35 parts of PU resin copolymer emulsion, 5 parts of polyvinyl alcohol, 0.6 part of defoamer, 0.2 part of inorganic fungicide, 2 parts of organic bentonite, 2 parts of magnetic ordered mesoporous carbon;

[0036] The inorganic bactericide is a mixture of zinc chloride and cuprous chloride in a mass ratio of 1:2, and the preparation process of the anti-mildew paper packaging box is carried out as follows:

[0037] (1) Processing of semi-finished cardboard for packaging boxes, the moisture content of semi-finished cardboard is ≤2.5%;

[0038] (2) Pretreatment of the semi-finished cardboard of the packaging box: process the semi-finished product of the packaging box in a dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com