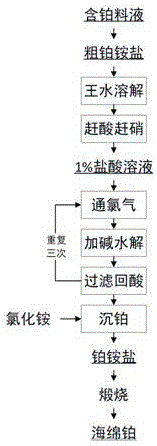

Platinum refining process

A technology of process and process steps, applied in the field of platinum refining process, to achieve the effect of reducing negative impact, being beneficial to production capacity, and improving direct yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The platinum-containing concentrate with a grade of more than 80% is filtered with a hydrochloric acid solution with a mass fraction of 1% after the primary dissolving liquid of aqua regia is driven by acid and nitrate; The filtrate of volume 900L controls the flow rate of chlorine gas to be 20L / min. The control temperature was 85℃, after measuring the potential of 1050mV, the color of the feed liquid became darker, and the chlorine gas was stopped; the pH value of the feed liquid was adjusted to 8 with liquid alkali, the temperature of the whole hydrolysis process was controlled at 85℃, and the stirring intensity during the alkali addition process was 80r / min , after the pH=8 was stabilized for 5 minutes, the filtrate was directly cooled and filtered, and the filtrate was orange-red; acidified to pH=1, and the above steps 2 and 3 were repeated three times. Return the obtained liquid after three hydrolysis to acid, control the acidity pH=1, add saturated ammonium chlori...

Embodiment 2

[0021] The platinum-containing concentrate with a grade of more than 80% is filtered with a hydrochloric acid solution with a mass fraction of 1% after the primary dissolving liquid of aqua regia is driven by acid and nitrate; The filtrate of volume 800L controls the flow rate of chlorine gas to be 10L / min. The control temperature is 75°C, after measuring the potential of 1000mV, the color of the feed liquid becomes darker, and the chlorine gas is stopped; the pH value of the feed liquid is adjusted to 9 with liquid caustic soda, the temperature of the whole hydrolysis process is controlled at 75°C, and the stirring rate is 120r / min, after pH=9 is stable for 7min, rapidly cool and filter, the filtrate is orange-red; return to acid to pH=1.5, repeat the above steps 2 and 3 three times. The obtained liquid after three hydrolysis is returned to acid, and the acidity is controlled between pH=0.5. After boiling, a saturated ammonium chloride solution with a volume ratio of 1:1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com