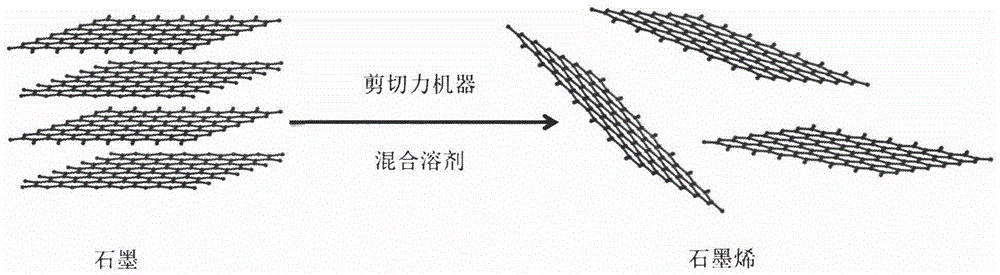

Method for peeling off graphite to obtain graphene based on shear force machine

A technology of exfoliating graphite and shear force, which is applied in the field of nanomaterial preparation, can solve the problems of high equipment requirements and high cost, and achieve the effect of simple raw materials and solvents, mild conditions, and no waste liquid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

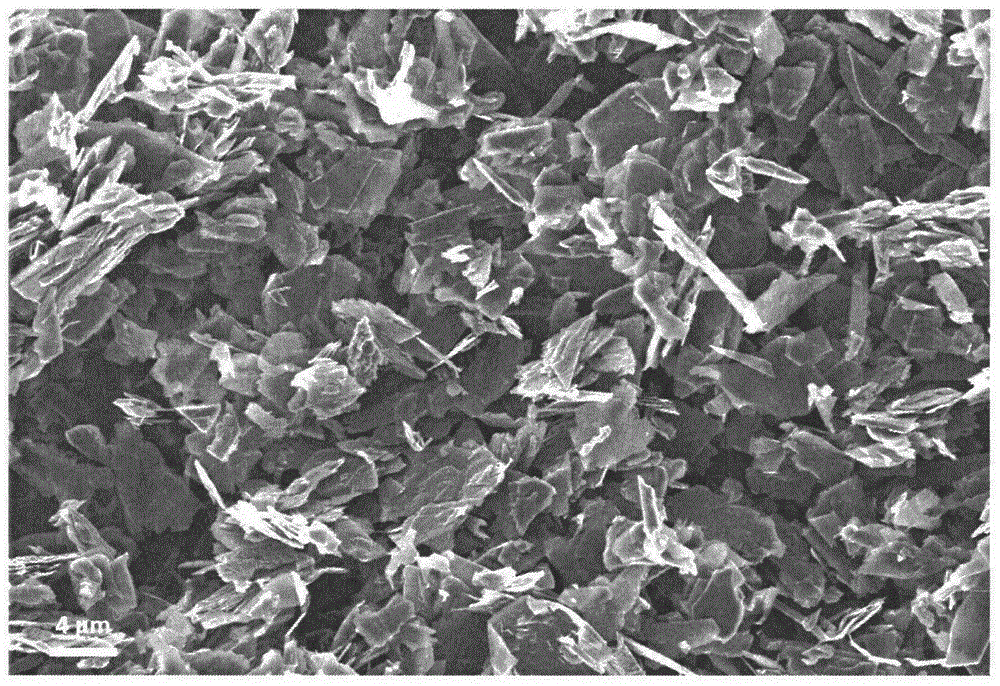

Examples

Embodiment 1

[0015] Step 1, weigh 50 mg of dense crystalline graphite and add it to 200 mL of water / ethanol (volume ratio 55:45):

[0016] In step 2, the uniformly mixed solution is placed in a shear force machine for 3 hours, and post-treatments such as standing still and centrifuging at 1000 rpm / min are performed to obtain graphene.

Embodiment 2

[0018] Step 1, weigh 50mg flake graphite and add in 200mL water / ethanol (volume ratio is 55:45);

[0019] In step 2, the uniformly mixed solution is placed in a shear force machine for 5 hours, and post-treatments such as standing still and centrifuging at 1000 rpm / min are performed to obtain graphene.

Embodiment 3

[0021] Step 1, weigh 50 mg of aphanitic graphite and add it to 200 mL of water / ethanol (volume ratio of 55:45);

[0022] In step 2, place the uniformly mixed solution in a shear force machine for 4 hours, and perform post-treatments such as standing still and centrifuging at 1000 rpm / min to obtain graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com